SensorMedics

Vyaire 3100A HFOV Operators Manual Ver A Jan 2020

Operators Manual

96 Pages

Preview

Page 1

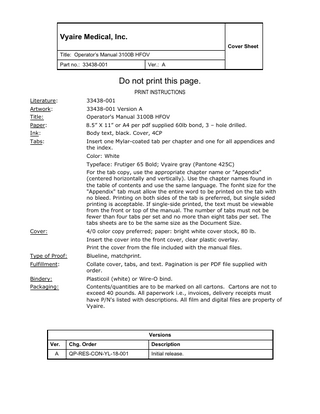

Vyaire Medical, Inc. Cover Sheet Title: Operator’s Manual 3100B HFOV Part no.: 33438-001

Ver.: A

Do not print this page. PRINT INSTRUCTIONS Literature:

33438-001

Artwork:

33438-001 Version A

Title:

Operator's Manual 3100B HFOV

Paper:

8.5” X 11” or A4 per pdf supplied 60lb bond, 3 – hole drilled.

Ink:

Body text, black. Cover, 4CP

Tabs:

Insert one Mylar-coated tab per chapter and one for all appendices and the index. Color: White Typeface: Frutiger 65 Bold; Vyaire gray (Pantone 425C) For the tab copy, use the appropriate chapter name or "Appendix" (centered horizontally and vertically). Use the chapter names found in the table of contents and use the same language. The fonht size for the "Appendix" tab must allow the entire word to be printed on the tab with no bleed. Printing on both sides of the tab is preferred, but single sided printing is acceptable. If single-side printed, the text must be viewable from the front or top of the manual. The number of tabs must not be fewer than four tabs per set and no more than eight tabs per set. The tabs sheets are to be the same size as the Document Size.

Cover:

4/0 color copy preferred; paper: bright white cover stock, 80 lb. Insert the cover into the front cover, clear plastic overlay. Print the cover from the file included with the manual files.

Type of Proof:

Blueline, matchprint.

Fulfillment:

Collate cover, tabs, and text. Pagination is per PDF file supplied with order.

Bindery:

Plasticoil (white) or Wire-O bind.

Packaging:

Contents/quantities are to be marked on all cartons. Cartons are not to exceed 40 pounds. All paperwork i.e., invoices, delivery receipts must have P/N's listed with descriptions. All film and digital files are property of Vyaire.

Versions Ver. A

Chg. Order

Description

QP-RES-CON-YL-18-001

Initial release.

3100B® High frequency oscillatory ventilator Operator’s manual

ii

3100B HFOV

This document is protected by United States and International Copyright laws. This document may not be copied, reproduced, translated, stored in a retrieval system, transmitted in any form, or reduced to any electronic medium or machine-readable form, in whole or in part, without the written permission of Vyaire. Information in this document is subject to change without notice. This document is for informational purposes only and should not be considered as replacing or supplementing the terms and conditions of the License Agreement. © 2019 Vyaire. Vyaire, the Vyaire logo, and all other trademarks or registered trademarks are property of Vyaire Medical, Inc., or one of its affiliates. US Vyaire Medical, Inc. 26125 North Riverwoods Blvd. Mettawa, IL 60045

EU Representative EMERGO EUROPE Prinsessegracht 20 2514 AP The Hague The Netherlands

1-833-327-3284

vyaire.com

Literature number: 33438-001 Revision A

33438-001 Rev. A

3100B HFOV

Notices Caution: Federal law restricts this device to sale by, or on the order of a physician Caution: Not suitable for use in the presence of flammable anesthetics Service of this instrument is restricted to factory-trained personnel only The benefit of treatment with medical respiratory support devices outweighs the remote possibility of exposure to phthalates.

33438-001 Rev. A

iii

3100B HFOV

iv

Contents Notices ... iii

Chapter 1 Introduction ... 1 Device Description... 1 Indications for Use... 1 Contraindications ... 1 Warnings ... 1 Cautions ... 3 Adverse Effects ... 5 Observed Adverse Events ... 5 Potential adverse events ... 5

Symbols ... 6 Exterior Labels ... 7 Patient Circuit Calibration ... 7 Ventilator Performance Checks ... 8 Blender/Cooling Gas Filter Replacement Record ... 9 Driver Replacement Record ... 9 Radio Frequency Interference (RFI) Warning ... 10 Name Rating Label ... 10 Battery Attachment ... 10 Battery Specification ... 10

Chapter 2 Clinical Study ...11 Inclusion and Exclusion Criteria ... 11 Methods ... 11 Hypothesis ... 12 Study Population ... 12 Results ... 14 Observed Treatment Failures ... 14 Causes of Death ... 15

33438-001 Rev. A

Operator’s Manual

Notices

v

Chapter 3 Specifications ... 17 Controls ... 17 Bias Flow ... 17 Mean Pressure Adjust ... 17 Mean Pressure Limit... 17 Power ... 17 Frequency ... 17 Inspiratory time ... 18 Start/Stop ... 18 Set Max Paw Alarm Thumbwheel ... 18 Set Min Paw Alarm Thumbwheel ... 18 45-Sec Silence ... 18 Reset ... 18 Patient Circuit Calibration ... 18 AC Power ... 18

Indicators ... 19 Pressure Measurement ... 19 Alarms ... 20 Safety Alarms ... 20 Warning Alarms ... 20 Caution Alarms ... 20

Electrical Specifications ... 21 Power Requirements ... 21 Leakage Current ... 21 Overload Protection ... 21 Power Line Connection ... 21

Regulatory Approvals ... 22 Pneumatic Connections ... 22 Inlet From Blender (Air/O2) ... 22 Air Cooling Inlet ... 22 Outlet To Humidifier... 22 Paw Control Valve ... 22 Paw Limit Valve ... 22 Dump Valve ... 22

33438-001 Rev. A

vi

3100B HFOV Paw Sensing... 22

Physical Specifications ... 23 Materials ... 23 Dimensions of Column & Control Package ... 23 Pedestal... 23 Required Operational & Environmental Conditions ... 23

3100B Performance Graphs ... 24 3–Ohm Driver Distal Tidal Volume vs. Frequency at Maximum Power ... 24 3–Ohm Driver Distal Tidal Volume vs. Power Setting at 33% I–Time ... 25 3–Ohm Driver Distal Tidal Volume vs. Frequency at Maximum Power and 33% I–Time ... 26 3–Ohm Driver Distal Tidal Volume vs. Frequency at Maximum Power and 50% I–Time ... 27 3–Ohm Driver Distal Tidal Volume vs. Power Setting at 50% I–Time ... 28

Chapter 4 Description of System & Safety Features ...29 Subsystems provided by the user... 29 Subsystems included with the ventilator ... 30

Chapter 5 Controls, Indicators and Connections ...41 Front and Side Panel – Control Package ... 41 Rear Panel – Control Package ... 46 System Column and Patient Circuit ... 48

Chapter 6 Assembly and Installation ...51 Unpacking the Instrument... 51 Assembly ... 51 Pre-use Cleaning and Disinfection ... 55

Chapter 7 Operational Verification and Start-up ...57 Start-up Procedures ... 57 Performance Verification ... 61

Chapter 8 Maintenance and Troubleshooting ...63 Exterior Cleaning ... 63 Operator Maintenance Procedures ... 63 Emptying the water trap ... 64 Changing the Gas Inlet Filter ... 64 Changing the Power Failure Alarm Battery ... 65 Clearing the Column Lint Filter ... 65

33438-001 Rev. A

Operator’s Manual

Notices

vii

Changing the Patient Circuit ... 65

Patient Circuit Calibration ... 66 Other Scheduled Periodic Calibration ... 66 DC Power Supply Calibration ... 67 Airway Pressure Monitor Transducer Calibration ... 68

Scheduled Periodic Maintenance ... 69 Troubleshooting ... 69 Special Environmental Considerations ... 69 Electrostatic Discharge ... 69 Electromagnetic Interference... 69 Troubleshooting Chart ... 70

Supplies and Replacements ... 75

Chapter 9 Clinical Guidelines ... 77 Treatment Strategies... 77 Adjusting the Controls to Execute the Treatment Strategies ... 77 Theraputic Objectives ... 79 General Aspects of Clinical Strategy ... 79 Special Considerations ... 80

Disease-Specific Variations to General Clinical Strategies ... 82 Homogeneous Lung Disease ... 82 Non-Homogeneous Lung Disease ... 82

Adverse Effects ... 82 Recommended Monitoring Frequency ... 83 Arterial Blood Gases... 83 Non-Invasive Blood Gas Monitoring (tcO2, tcCO2, SpO2) ... 83 Chest X-Ray ... 83

Suctioning Guidelines ... 83 Disconnection & Reconnection... 84

Index ... 85

33438-001 Rev. A

3100B HFOV

1

Chapter 1 Introduction Device Description This device is a high frequency oscillator ventilator. An earlier version of this device (the 3100A HFOV) has approval for treatment of respiratory failure in infants and children. This version of the device, the 3100B HFOV, now has increased power capability and other modifications to allow treatment of adults. In a simplified description the patient circuit of the ventilator is a high-flow CPAP system. Oscillations are superimposed on the gas in the patient circuit using an electrically-driven diaphragm, similar to an audio loudspeaker cone. The oscillation frequency and magnitude can be varied. The frequency can be set between 3 and 15 cycles per second. The mean airway pressure can be set from approximately 5 to 55 cmH2O and the bias flow (continuous sweep flow through the circuit) can be set from 0 to 60 liters per minute. The maximum pressure swing is approximately 140 cmH2O measured at the patient circuit. Corresponding pressure swings in the trachea would be in the range of 10% of this value because of attenuation in the tracheal tube. The maximum tidal volume will be approximately 250 ml depending on the ventilator settings, tracheal tube size and the patient's pulmonary compliance. Typical settings are considerably less than these maximum values. The tidal volumes typically used are similar to the volume of the anatomic dead space. Various mechanisms have been described to explain how these small volumes cause effective gas exchange (summarized in Krishnan and Brower, 2000). The Vyaire 3100 B includes alarms for overpressure and low pressures that will detect certain problems such as circuit disconnects, and some partial obstructions. The air-oxygen blender, oxygen monitor, and humidifier are connected before the gas inlet to the patient circuit; these elements are conventional and are provided by the user.

Indications for Use The Vyaire 3100B is indicated for use in the ventilatory support and treatment of selected patients 35 kilograms and greater with acute respiratory failure.

Contraindications The Vyaire 3100B Oscillatory Ventilator has no specific contraindications.

Warnings The following Warnings must be read and understood before an attempt is made to operate the Model 3100B HFOV: The Model 3100B was not studied for use in children. Similar devices, Vyaire 3100 and 3100A, are indicated for use in infant and children. Do not attempt to defeat the proper connection of the ground wire as it may cause damage to the device or interconnected equipment and could be injurious to the patient or to those associated with the device use. This device is factory equipped with a hospital-grade AC power plug. Grounding reliability can only be assured when connected to a tested receptacle labeled “Hospital Grade.” Do not operate radio transmitters within 20 feet of this instrument. This may result in erroneous pressure readings leading to false alarms and automatic shutdown. 33438-001 Rev. A

2

3100B HFOV Do not shorten the 30” bias flow tube provided with the patient circuit as this may reduce the maximum P by allowing the oscillatory pressures to be attenuated by closer proximity to the volume of the humidifier canister. Do not attempt to substitute a circuit configuration from any other instrument. Use of a non-3100B circuit can result in injury to the patient or to the operator, and it may cause damage to the equipment. The Patient Circuit described in this manual is specifically designed for patient use with the Model 3100B HFOV. There is no data to suggest that aerosols can be effectively delivered during high frequency oscillatory ventilation. Use of conventional aerosol therapy with the 3100B will probably be ineffective. Therefore, alternative vehicles for drug delivery should be considered for patients requiring this therapy. The operational verification and startup procedure (Chapter 7) must be followed before ventilation of a patient commences. If at any time during the operational verification and startup procedure any abnormal function of the Model 3100B HFOV is noted, do not proceed with patient ventilation as this could cause patient injury or death; immediately contact Vyaire Technical Support before proceeding any further. An audible alarm indicates the existence of a condition potentially harmful to the patient and should not go unattended. Failure to respond to alarms could result in injury (including death) to the patient and/or damage to the ventilator. Ensure that the cooling fan at the rear of the driver enclosure is operational. Under no circumstances should the ventilator be used in the presence of flammable anesthetics due to the possibility of explosion. Under no circumstances should a proximal airway gas temperature of 41°C be exceeded. This could result in injury to the patient's airway membranes. Do Not use the 3100B ventilator in environments where the ambient temperature is at or above 84F (28C). Use of the ventilator in these environments will result in extreme reduction in relative humidity in the patient’s airway and possible desiccation of the patient airways. Failure to comply with the recommended maintenance procedures described in Chapter 8 could result in injury to the patient or operator or could result in damage to the equipment. Severe COPD and asthma were exclusion criteria from the randomized controlled trial of the 3100B. The benefits and/or risks associated with use of the 3100B in these patients are unknown. High frequency oscillatory ventilation is known to be less effective in diseases with increased airway resistance and its use may potentially result in air trapping and hyperinflation. This should be taken into consideration if used in these patients.

33438-001 Rev. A

Operator’s Manual

3

Cautions The following Cautions must be read and understood before an attempt is made to operate the Model 3100B HFOV: Follow closely the recommendations contained in Chapter 9, Clinical Guidelines, regarding the use of chest radiographs to monitor patient condition. During HFOV, as with all ventilators, the relationship between improvement in lung compliance, inadvertent increases in lung volume, increased pleural pressure, and decreased venous return is a matter of concern, since it may result in decreased cardiac output. Patient size is an important guideline as to lung volume and anatomical dead space, as well as the metabolic demand placed on ventilation. While the maximum displacement volume of the 3100B is approximately 365 ml, the actual volume delivered to the patient is dependent on power setting, frequency, endotracheal tube size, and patient respiratory system compliance. It is recommended that the operator review Chapter 9 of this manual, “Clinical Guidelines.” The patient's tcPCO2 and tcPO2 or SpO2 should be monitored continuously to insure that blood gases are at the proper level. It is important that an unrestricted and unobstructed patient airway be maintained during HFOV. To insure a patent airway, always maintain proper suctioning procedures as described in the Suctioning Guidelines Section of Chapter 9, Clinical Guidelines. Since only proximal airway pressure is measured, no alarm will occur in the event of an obstruction or restriction. Ensure that the stopcock is closed prior to performing a Patient Circuit Calibration. If the Water Trap Stopcock is left open, Patient Circuit Calibration (39-43 cmH2O) may not be achievable, and the deliverable Paw will be reduced. Deviation from the assembly methods described in Chapter 6, Assembly and Installation, could damage the Model 3100B, render it mechanically unstable, or cause it to malfunction. If any questions arise regarding the assembly procedure, please contact Vyaire Technical Support immediately before proceeding. Care should be taken not to crimp or perforate any of the control or sensing lines (running to or from the Patient Circuit) during assembly, operating or cleaning of the ventilator as this will cause malfunction of the Safety Alarms, Warning Alarms, Caution Alarms, and/or Pressure Limit Controls. Before attaching the patient circuit to the ventilator, the driver diaphragm of the 3100B should be inspected for cuts and tears. If any damage is noted, do not proceed with patient ventilation as this could cause failure of the ventilator. Immediately contact Vyaire Technical Support for assistance. The driver diaphragm of the 3100B has been coated with a special lubricant during assembly. Please do not clean the driver diaphragm with cleaning solvents as it may degrade the materials causing premature wear of the driver diaphragm. When connecting the Patient Circuit, make certain that it is properly supported and oriented by the support arm as described in Chapter 6, Assembly and Installation. Failure to do so could result in inadvertent Patient Circuit disconnection due to oscillatory forces or could result in collection of humidifier condensate in the patient airway. If the temperature probe is wiped with alcohol, allow the alcohol to evaporate completely before inserting it into the circuit. A high residual of alcohol can weaken the acrylic adapter and cause fracturing.

33438-001 Rev. A

4

3100B HFOV Proper operation of the ventilator must be verified prior to each use. Refer to Chapter 7, Operational Verification and Startup Procedures. The alarm functions tested in this procedure verify the capability of the device to detect and indicate conditions that could have a harmful effect on the patient. Touch the outer metal cabinet of the instrument before touching any other component to avoid possible instrument component damage from Electrostatic Discharge. When the ventilator is connected to a patient, it is imperative that someone be in attendance at all times in order to react to any alarms and to detect other indications of a problem. The Inlet Filter Cartridges for the blended gas and the air inputs to the ventilator must be changed at least every 500 hours of operation as described in Chapter 8, Maintenance and Troubleshooting. Failure to replace a Filter Cartridge or substitution of an unauthorized cartridge could result in injury to the patient and/or damage to the equipment. Use only Vyaire Inlet Filter Cartridges. The filter cartridge body must be screwed back on securely. Cross-threaded or loose installation will result in leaks and possible dislodging of the cartridge body. If the cartridge body is dislodged, it will cause the ventilator to cease functioning. Covers enclosing the Control Package, Column, or any other portion of the ventilator, must not be removed by the user. To avoid electrical shock hazard, please refer all service requiring cover removal to a qualified biomedical equipment service technician. Recheck and readjust alarm levels after any parameter change has been made. Troubleshooting with the 3100B should be done “OFF PATIENT” to avoid any potentially dangerous situations such as abrupt changes in the Paw. Do not use extraneous ventilator circuit attachments (such as a suction port) without a secondary external alarm capable of detecting ventilator disconnection. Due to their inline pressure characteristics, such attachments could possibly keep the Paw alarm from detecting an accidental ventilator circuit disconnection. Fractional concentration of inspired oxygen should be verified with an oxygen monitor. Administration of excessive oxygen to a patient may be harmful. It is imperative that the prescribed gas mixture is delivered by the blending system. The Water Trap must be drained at intervals as described in Chapter 8, Maintenance and Troubleshooting. If the ventilator is operating, leave a small amount of water at the bottom of the Water Trap container to act as a flow and pressure seal between the ventilator and the output of the drain. To help prevent patient injury due to humidifier malfunction, the use of a humidifier with the following characteristics is strongly recommended: Thermally protected heater. Alarms on over-filled water reservoir. Alarms on under-filled water reservoir. Alarms when electrically open or shorted temperature probe detected. Alarms at probe temperatures > 41°C. Alarms when dislodged temperature probe detected. Do not place on the Control Package of the ventilator any fluid-containing accessories, accessories that weigh more than ten pounds, or accessories that extend more than six inches above the ventilator electronics package or beyond its sides. This could cause damage to the ventilator,

33438-001 Rev. A

Operator’s Manual

5

or could cause the ventilator to tip over, resulting in patient or user injuries and/or damage to the equipment. Do not overturn the Patient Circuit Calibration screw, as this may cause damage to the device. When it is nearing its adjustment limit, it will reach a mechanical stop. Do not allow liquids to penetrate the air vents of the ventilator as this may result in machine failure or malfunction. Do not use a liquid sterilization agent on the outside of the ventilator as this may cause damage.

Adverse Effects Observed Adverse Events A prospective clinical study of the Model 3100B in patients with acute respiratory distress syndrome (ARDS) was conducted at ten sites. The 148 patients enrolled in the study were randomly assigned to one of two groups: a treatment (i.e., “high-frequency”) group, in which patients were treated with the Model 3100B; or a control (i.e., “conventional”) group, in which patients were treated with a conventional ventilator. Treatment outcomes and adverse events were determined at one and six months. Table 1 summarizes the adverse events observed during the study. Table 1: Observed adverse events

Adverse event

# (%) of patient who had this event in the treatment group, N=75

Mucus-plugged ET tube

2 (3%)

Inadequate Oxygenation

4 (5%)

Respiratory acidosis

4 (5%)

New or worsening air leak syndrome

7 (9%)

Intractable hypotension

0 (0%)

Potential adverse events The adverse events associated with the use of high-frequency ventilation include: atelectasis, inadequate oxygenation, intractable hypotension, mucus-plugging of the tracheal tube, necrotizing tracheobronchitis, new or worsening air leak syndrome, over-humidification, under-humidification, overventilation, under-ventilation, pneumothorax, pneumopericardium, pneumomediastinum, pneumoperitoneum, pulmonary interstitial emphysema and respiratory acidosis.

33438-001 Rev. A

6

3100B HFOV

Symbols The following symbols are used on this device: Symbol

Compliance Symbol #03-02 IEC 60878

Symbol # 5333 IEC 60417 Symbol #02-03 IEC 60878

Symbol #5032 IEC 60417

Meaning Indicates ATTENTION, consult ACCOMPANYING DOCUMENTS

This symbol indicates TYPE B equipment, which indicates equipment that provides a particular degree of protection against electric shock, particularly with regards to allowable leakage current and reliability of the protective earth connection.

Symbol #01-14 IEC 30878

This symbol indicates the equipment is suitable for alternating current.

Symbol #5007 IEC 60417 Symbol #01-01 IEC 60878

Indicates circuit breaker ON (Power)

Symbol #5008 IEC 60417 Symbol #01-02 IEC 60878

Indicates circuit breaker OFF (Power)

Vyaire Symbol

Position Lock. Clockwise rotation locks instrument top. Counterclockwise rotation unlocks instrument top, allowing it to be swiveled for best view of front controls and displays.

Vyaire symbol

This symbol indicates the product contains phthalates.

Medical Device

Authorized Representative in the European Community

33438-001 Rev. A

Operator’s Manual

7

Exterior Labels This section identifies the labels attached to the exterior of the 3100B. All labels are shown at approximately their actual size. Your system may not have all of the labels listed.

Patient Circuit Calibration

PATIENT CIRCUIT CALIBRATION PROCEDURE OFF-PATIENT

IMPORTANT–Before use on a patient, each patient circuit must be calibrated to the Model 3100B by following this procedure: 1. Insert stopper in Patient Circuit “Y” and turn on Bias Flow gas. 2. Rotate Mean Pressure ADJUST control to “Max.” 3. Set Max Pa Alarm to 59 cm H2O. 4. Adjust Bias Flow to 20 LPM. 5. Depress and hold RESET (Oscillator OFF). 6. Observe Mean Pressure display and adjust Patient Circuit Calibration screw for a reading of 39–43 cm H2O. P/N 772754A

Figure 1.1. Patient Circuit Calibration Procedure Label.

The Patient Circuit Calibration Procedure Label describes the steps necessary to calibrate the patient circuit to the 3100B. This procedure is also explained in the Patient Circuit Calibration Section of Chapter 8, Maintenance and Troubleshooting.

33438-001 Rev. A

8

3100B HFOV

Ventilator Performance Checks

Figure 1.2. Ventilator Performance Checks Label.

The Ventilator Performance Checks Label assists in setting Power, Mean Pressure Adjust, and Bias flow controls to achieve specific ranges of P and Paw. These procedures are explained in the Performance Verification Section of Chapter 7, Operational Verification and Start-up Procedures.

33438-001 Rev. A

Operator’s Manual

9

Blender/Cooling Gas Filter Replacement Record

The Blender/Cooling Gas Filter Replacement Record Label provides a place to document the 500 hour gas filter changes. For more information, see the Operator Maintenance Procedures Section of Chapter 8, Maintenance and Troubleshooting.

Figure 1.3. Blender/Cooling Gas Filter Replacement Record Label

Driver Replacement Record

The Driver Replacement Record Label provides a place to document the 4,000 hours replacement of the Oscillator Subassembly. For more information, see the Scheduled Periodic Maintenance Section of Chapter 8, Maintenance and Troubleshooting.

Figure 1.4. Driver Replacement Record Label.

33438-001 Rev. A

10

3100B HFOV

Radio Frequency Interference (RFI) Warning The Radio Frequency Interference (RFI) Warning Label refers to the possible problems caused by interference from hand-held radio transmitters. The RFI warning is also discussed in the Troubleshooting Section of Chapter 8, Maintenance and Troubleshooting.

Figure 1.5. Radio Frequency Interference Warning Label.

Name Rating Label

Vyaire Medical, Inc. 26125 North Riverwoods Blvd. Mettawa, IL 60045 33606-001 USA

The Name Rating Label lists specific information on each individual instrument: the Model Name and Number, the Voltage and Current Rating, the Serial Number, and the instrument’s Catalog Part Number. (The example shown is for the 115V, 7.5A, 60Hz model; your instrument may have a different rating.)

Figure 1.6. Name Rating Label.

Battery Attachment The Battery Attachment Label indicates the correct position for the installed Power Failure Alarm Battery. For directions on changing the battery, see the Changing the Power Failure Alarm Battery Section of Chapter 8, Maintenance and Troubleshooting. Figure 1.7. Battery Attachment Label.

Battery Specification The Battery Specification Label indicates the type of Power Failure Alarm Battery (9V alkaline) that must be used. For directions on changing the battery, see the Changing the Power Failure Alarm Battery Section of Chapter 8, Maintenance and Troubleshooting. Figure 1.8. Battery Specification Label.

33438-001 Rev. A

3100B HFOV

11

Chapter 2 Clinical Study A prospective clinical study of the Model 3100B in patients with acute respiratory distress syndrome (ARDS) was conducted at ten sites. The 148 patients enrolled in the study were randomly assigned to one of two groups: a treatment (i.e., “high-frequency”) group, in which patients were treated with the Model 3100B; or a control (i.e., “conventional”) group, in which patients were treated with a conventional ventilator.

Inclusion and Exclusion Criteria Patients were eligible for inclusion in the study if they met the following criteria: at least 16 years of age; at least 35 kilograms; PaO2/FiO2 < 200; bilateral pulmonary infiltrates not resulting from left atrial hypertension; and positive end-expiratory pressure (PEEP) of at least 10 cm H2O. Patients were excluded if any of the following were true: informed consent could not be obtained; patient had been treated with FiO2 greater than 80% for at least 48 hours; patient had severe persistent air leak; patient had non-pulmonary terminal prognosis; patient had severe chronic obstructive pulmonary disease patient had asthma; or patient had been recently enrolled in another ARDS or septic shock investigation.

Methods The general treatment goal for the high-frequency group and the conventional group was the same: to maintain an O2 saturation of at least 88%; and to maintain a pH of greater than 7.15, while minimizing peak pressures and treating metabolic acidosis. The mean airway pressure was maintained until FiO2 had been reduced to less than 60%, after which mean airway pressure and FiO2 were given equal priority for reduction. In the high-frequency group, the Model 3100B was initially set to provide pressure oscillations at a frequency of 5 Hz, with the mean airway pressure set 5 cm H2O higher than the ventilator setting used before the patient was enrolled in the study, and with the oscillation amplitude (∆P) set for adequate chest wall vibration. If ventilation was inadequate, ∆P was increased. If ventilation was still inadequate with maximum ∆P, the frequency of pressure oscillations was reduced in 1 Hz steps. When mean airway pressure had been decreased to less than 30 cm H2O, or when there was no progress in weaning with the Model 3100B, ventilator weaning continued using a conventional ventilator. A patient assigned to the high-frequency group was treated with the Model 3100B protocol until: consent was

33438-001 Rev. A

12

3100B HFOV withdrawn; the patient had died or been weaned from mechanical ventilation; the patient had been ventilated for 30 days; or the patient met defined treatment failure criteria and would, in the opinion of their physician, benefit from conventional ventilation. In the conventional group, patients were treated with conventional pressure-control, volume-limited ventilation with an inspiratory to expiratory (I:E) ratio of approximately 1:2. Tidal volumes nominally between 6 and 10 mL/kg were used. (The average tidal volume delivered was 10.2 mL/kg of ideal body weight.) If oxygenation was inadequate, PEEP was increased in increments of up to 5 cm H2O to improve oxygenation. If oxygenation was still inadequate with PEEP greater than or equal to 18 cm H2O, the I:E ratio was increased incrementally. A patient assigned to the conventional ventilation was treated within the study with the conventional ventilator until: consent was withdrawn; the patient had died or been weaned from mechanical ventilation; or the patient had been ventilated for 30 days. Patient outcomes were determined after one month and six months. The possible outcomes were: death; survival with respiratory support; or survival without respiratory support. In this trial, “respiratory support” was defined to include mechanical ventilation, CPAP or supplemental oxygen. Only survival without respiratory support was considered a successful outcome. Outcome data were analyzed using an “intention to treat” analysis.

Hypothesis The primary hypothesis was that the proportions of patients in the high-frequency and conventional groups with unsuccessful one-month outcomes would be equivalent. Statistically stated, the hypothesis was that the proportion of patients with an unsuccessful one-month outcome, i.e., the proportion of patients who died or were still receiving respiratory support after one month, would be no more than 10% greater in the high-frequency group than in the conventional group, with 95% confidence.

Study Population In this trial, 75 patients were assigned to the high-frequency group, and 73 patients were assigned to the conventional group. The patient demographics, the pre-enrollment diagnoses, the pre-enrollment ventilator settings and the pre-enrollment clinical indicators were similar for the two groups (Table 3).

33438-001 Rev. A