Operators Manual

13 Pages

Preview

Page 1

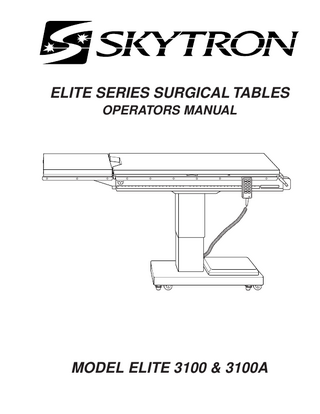

ELITE SERIES SURGICAL TABLES OPERATORS MANUAL

MODEL ELITE 3100 & 3100A 13

MODEL 3100 SKYTRON STANDARD LIMITED WARRANTY SKYTRON, a Division of the KMW Group, Inc. (SKYTRON) warrants all new products sold by it directly or through a dealer or other authorized representative, with exception to replacement parts, spares, bulbs (surgical lights), pads, and accessory items (surgical tables) to be free from defects in material or workmanship, under normal use and service, for a period of two (2) years. This warranty shall include the cost of repair or replacement of defective parts including the cost of service labor and travel time to the site of equipment use. Delays caused by the user in accessing the equipment for repair will be chargeable at the normal hourly rate for service by SKYTRON’s authorized service representative. The warranty period shall begin with the initial operation or one (1) year after receipt of the product, whichever shall occur first. Replacement parts, spares, bulbs (surgical lights), pads and accessory items (surgical tables) are warranted to be free from defects in material or workmanship, under normal use and service, for a period of ninety (90) days from receipt by the ultimate user, with exception to replacement parts supplied by SKYTRON, for products under warranty, which shall be covered for any remaining period of the original product warranty, or for 90 days, whichever is of greater benefit to the ultimate user. SKYTRON’s responsibility and liability shall be limited to the repair or replacement of any part which we, SKYTRON, determine to be defective within the applicable warranty period. Minor adjustments required as a result of normal wear during the use of the product within the warranty period are not covered under warranty. The labor portion of this warranty is covered by SKYTRON’s Authorized Service Agent. Repairs made by others are not authorized nor covered by SKYTRON with respect to labor costs. SKYTRON shall not be liable for any other expense, loss or damage, whether direct, incidental, consequential or exemplary arising in connection with the sale or use of or the inability to use SKYTRON products. NO EXPRESS WARRANTY IS GIVEN BY SKYTRON WITH RESPECT TO ITS PRODUCTS EXCEPT AS SPECIFICALLY SET FORTH HEREIN. ANY WARRANTY IMPLIED BY LAW, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, IS EXPRESSLY LIMITED TO THE TWO-YEAR AND 90-DAY TERMS SET FORTH ABOVE. THE FOREGOING STATEMENTS OF WARRANTY ARE EXCLUSIVE AND IN LIEU OF ALL OTHER REMEDIES. No dealer, agent, employee or other representative of SKYTRON is authorized to extend or enlarge this warranty.

4/00 Although current at the time of publication, SKYTRON’s policy of continuous development makes this manual subject to change without notice.

9

TABLE OF CONTENTS Title

Page

SPECIAL USER ATTENTION ...1 SECTION I INTRODUCTION ...2 1-1. General ...2 1-2. Power Requirements ...2 1-3. Pendant Control Unit ...3 1-4. Floor Lock / Brake System ...3 SECTION II OPERATION ...4 2-1. Electrical Power ...4 2-2. Pendant Control Unit ...4 2-3. Leg Section ...6 2-4. X-ray Cassette Tray . ...7 SECTION III MAINTENANCE ...8 3-1. Preventive Maintenance ...8 3-2. Service ...8

11

SPECIAL USER INFORMATION

The extreme positioning capabilities of the 3100 series tables requires special attention for possible interference points when using multiple function positioning. As with the operation of any surgical table, a certain amount of care should be exercised to position the patient safely. Although the thick pads and sheets substantially protect the patient, pinch points, located at the joints of the top section should always be considered. BE SURE THAT THE ARMS, HANDS AND FINGERS OF THE PATIENT, AND THOSE OF THE OPERATING ROOM PERSONNEL, ARE CLEAR OF ALL MOVING PARTS BEFORE MOVING THE TABLE. Proper restraints should always be used for patient safety.

NOTE In case of a power failure or an electrical problem within the table, the emergency brake release system can be used to move the table. The control lever for this function is located on the side of the table base and is identified by an EMERGENCY BRAKE RELEASE label. Turn the lever counterclockwise to release the brakes.

Certain accessories can be damaged when changing the position of the table top sections. Always look first to see if a desired movement is going to interfere with any accessories in use.

IMPORTANT •The Emergency Brake Release Valve must be tightened securely when not in use.

The operator has the ultimate responsibility of preventing damage or possible injury. In general, common sense will dictate when there is a potential hazard.

•If the Emergency Brake Release Valve has been operated, the BRAKE UNLOCK button on the pendant control will have to be pressed before brakes will lock again.

The following precautions should be reviewed by all personnel prior to operating the table. WARNING DO NOT use the table in the presence of FLAMABLE GASES.

NOTE The Emergency Brake Release Valve must be closed before any hydraulic function will operate.

NOTE The table will lift and articulate a patient weight of 500 pounds assuming normal positioning of the patient.

NOTE Activating any function button will activate the brake system. Using the TABLE UP function to set the brakes provides a visual assurance that the brakes are locked. As the brake cylinders are extending, the entire table will move slightly. When the table top begins to elevate, the brakes are fully locked. WARNING DO NOT unlock brakes when a patient is on the table. An uneven patient weight load may cause instability.

1

SECTION I INTRODUCTION LEG SECTION

X-RAY CASSETTE TRAVEL INDICATOR

CASSETTE TRAY POSITIONING GUIDE X-RAY CASSETTE POSITIONING CRANK

KIDNEY BRIDGE

PENDANT CONTROL

ELECTRICAL ENCLOSURE

Figure 1-1. Model 3100 Surgical Table 1-1. General SKYTRON’s Model 3100 and 3100A surgical tables are electro-hydraulically operated surgical tables with special x-ray equipment compatibility features. See figure 1-1.

Manual controls are provided for cassette tray positioning, emergency brake release, and leg section removal.

A longitudinal top slide capability of 23-1/2 inches allows clearance for C-arm coverage of 58-3/4 inches without the need to reposition the patient. Xray cassettes can be loaded into a movable tray from the head end of the table. A manual hand crank system allows cassette positioning throughout an unobstructed range of 65 inches. A travel indicator next to the hand crank indicates where the center of the cassette tray is located in relation to the positioning guide on the side of the table for precise x-ray positioning. The full radiographic table top allows clear sharp x-rays throughout the cassette travel range.

1-2. Power Requirements

The hydraulically-operated (built-in) kidney bridge on the Model 3100 is made up of movable table top sections. This allows total unobstructed radiographic capability with the kidney bridge in use. The kidney bridge is not available on Model 3100A. The push button, pendant control unit operates the kidney bridge function (Model 3100) as well as the trendelenburg, lateral tilt, top slide, elevation, and the floor lock/brake system functions.

2

The Elite 3100 series tables require a 120VAC, 60 Hz electrical power supply. The table is equipped with a 15 foot long, power cord with a standard three prong, hospital grade plug. The electrical protection fuses are located on the front edge of the base. See figure 1-2. The main power ON/ OFF switch is located on the electrical enclosure. ELECTRICAL ENCLOSURE

POWER CORD MAIN POWER SWITCH

COVER PLATE

FUSE

Figure 1-2. Power Switch and Fuse Location

1-3. Pendant Control Unit The hand-held pendant control unit (figure 1-3) has a non slip rubber cover which assures a positive grip during use. A spring clip hanger located on the back of the control allows it to be stored on the table side rails. CLIP

TRE . REV D N TRE

E SLID D HEA

E

* SFLOIDOT

NEY KID WN DO

NEY KID P U UR

PRE

SS

To unlock the brakes, press the BRAKE UNLOCK button and release. The brakes will retract automatically in approximately 7-8 seconds.

E AK BR OCK L UN

N

POW

*

FUNCTION BUTTONS

LE TABWN DO

LE TABP U

RET

ND

TILTT H RIG

TILTT LEF

NOTE Activating any function button will activate the brake system. Using the TABLE UP function to set the brakes provides a visual assurance that the brakes are locked. As the brake cylinders are extending, the entire table will move slightly. When the table top begins to elevate, the brakes are fully locked.

L TO

OC

KB

ER

RA

WARNING DO NOT unlock brakes when a patient is on the table. An uneven patient weight load may cause instability.

ON

KES

POWER INDICATOR

Figure 1-3. Pendant Control Unit The function push buttons are identified with abbreviated descriptions for all functions. See figure 1-4. The trendelenburg and table up buttons are red, the remaining buttons are all black. REVERSE TRENDELENBURG

REV. TREND.

TREND

TRENDELENBURG

LATERAL TILT LEFT

TILT LEFT

TILT RIGHT

LATERAL TILT RIGHT

TABLE UP

TABLE UP

TABLE DOWN

TABLE DOWN

SLIDE FOOT END

SLIDE FOOT

SLIDE LEG

SLIDE HEAD END

KIDNEY BRIDGE UP (3100) RETURN

KIDNEY UP

KIDNEY DOWN

RETURN

BRAKE UNLOCK

KIDNEY BRIDGE DOWN (3100) BRAKE RELEASE

NOTE In case of a power failure or an electrical problem within the table, the emergency brake release system can be used to move the table. The control lever for this function is located on the side of the table base and is identified by an EMERGENCY BRAKE RELEASE label. Turn the lever counterclockwise to release the brakes. NOTE The Emergency Brake Release Valve must be closed before any hydraulic function will operate. IMPORTANT •The Emergency Brake Release Valve must be tightened securely when not in use.

POWER ON

POWER ON INDICATOR * PRESS TO LOCK BRAKES

Figure 1-4. Function Push Buttons

•If the Emergency Brake Release Valve has been operated, the BRAKE UNLOCK button on the pendant control will have to be pressed before brakes will lock again.

1-4. Floor Lock/Brake System The floor lock/brake system consists of four selfleveling, hydraulic brake cylinders which raise and support the table base off from the casters. Press the TABLE UP button on the pendant control to set the table’s brakes. An electronic timer in the brake circuit will activate the brake system until the brakes are completely set, approximately 8-10 seconds.

3

SECTION II OPERATION

2-1. Electrical Power a. Check to be sure power cord is plugged into 120VAC outlet. IMPORTANT Prior to operating the table, review the SPECIAL USER ATTENTION section on page 1. b. Depress “Main Power ON/OFF” switch on the electrical enclosure. See figure 2-1. The green Power On indicator light on the pendant control unit should now be illuminated. POWER CORD

a. Floor Lock/Brake System. To activate the brakes without affecting table positioning, press the TABLE UP button. See figure 2-3. The elevation cylinder will not function until the brakes are completely extended. An electronic timer in the brake circuit will activate the brake system until the brakes are completely set, approximately 8-10 seconds.

REV. TREND.

TREND

TILT LEFT

TILT RIGHT

TABLE UP

TABLE DOWN

SLIDE FOOT

SLIDE HEAD

KIDNEY UP

KIDNEY DOWN

TABLE UP RETURN

BRAKE UNLOCK

POWER ON

BRAKE RELEASE

PRESS TO UNLOCK BRAKES

Figure 2-3. Brake System Activation

MAIN POWER SWITCH

ELECTRICAL ENCLOSURE

Figure 2-1. Main Power Switch 2-2. Pendant Control Unit The hand-held pendant control unit (figure 2-2) activates the following table functions:

REVERSE TRENDELENBURG

REV. TREND.

TREND

TRENDELENBURG

LATERAL TILT LEFT

TILT LEFT

TILT RIGHT

LATERAL TILT RIGHT

TABLE UP

TABLE UP

TABLE DOWN

TABLE DOWN

SLIDE FOOT END

SLIDE FOOT

SLIDE LEG

SLIDE HEAD END

KIDNEY BRIDGE UP (3100) RETURN

KIDNEY UP

KIDNEY DOWN

RETURN

BRAKE UNLOCK

KIDNEY BRIDGE DOWN (3100) BRAKE RELEASE

POWER ON

POWER ON INDICATOR * PRESS TO LOCK BRAKES

Figure 2-2. Pendant Control Unit

4

Press the BRAKE UNLOCK button on the pendant control to release the four self-leveling brake feet in order to move the table. See figure 2-3. The brake delay circuit automatically retracts the brake system with just one press of the BRAKE UNLOCK button. It takes approximately 7-8 seconds to totally release the system. WARNING DO NOT unlock brakes when a patient is on the table. An uneven patient weight load may cause instability. b. Emergency Brake Release. In case of a power failure or an electrical problem within the table, an emergency brake release system can be used to move the table. The control lever for this function is located on the side of the table base and is identified by an EMERGENCY BRAKE RELEASE label. Turn the lever counterclockwise to release the brakes. See figure 2-4.

d. Lateral Tilt. To achieve lateral tilt right (as viewed from the head end of the table), press the TILT RIGHT button (figure 2-6). Tilt of up to 20° may be obtained. To achieve lateral tilt left, press the TILT LEFT button. Tilt of up to 20° may be obtained.

REV. TREND.

LATERAL TILT LEFT

Figure 2-4. Emergency Brake Release NOTE The Emergency Brake Release Valve must be closed before any hydraulic function will operate.

TREND

TILT LEFT

TILT RIGHT

TABLE UP

TABLE DOWN

SLIDE FOOT

SLIDE HEAD

LATERAL TILT RIGHT

KIDNEY UP

KIDNEY DOWN

RETURN

BRAKE UNLOCK

POWER ON

PRESS TO UNLOCK BRAKES

20˚

20˚

IMPORTANT •The Emergency Brake Release Valve must be tightened securely when not in use. •If the Emergency Brake Release Valve has been operated, the BRAKE UNLOCK button on the pendant control will have to be pressed before brakes will lock again. c. Trendelenburg. To place the surgical table in a trendelenburg (head down) position, press the TREND button. See figure 2-5. Tilt of up to 20° may be obtained. To place the table in a reverse trendelenburg (head up) position, press the REV TREND button. Tilt of up to 20° may be obtained.

Figure 2-6. Lateral Tilt Positioning e. Elevation. To raise table top, press the TABLE UP button (figure 2-7.). The table will lift a patient weight of 500 pounds up to a maximum height of 40". To lower the table top, press the TABLE DOWN button. The table top will go down to a minimum height of 29".

REV. TREND.

REVERSE TRENDELENBURG

TRENDELENBURG

TREND

TILT LEFT

TILT RIGHT

TABLE UP

TABLE DOWN

REV. TREND.

TREND

SLIDE FOOT

SLIDE HEAD

TILT LEFT

TILT RIGHT

KIDNEY UP

KIDNEY DOWN

TABLE UP

TABLE DOWN

RETURN

SLIDE FOOT

SLIDE HEAD

KIDNEY UP

KIDNEY DOWN

RETURN

BRAKE UNLOCK

TABLE UP

TABLE DOWN

BRAKE UNLOCK

POWER ON

PRESS TO UNLOCK BRAKES

POWER ON

20˚

PRESS TO UNLOCK BRAKES

40" 20˚

Figure 2-5. Trendelenburg Positioning

29"

Figure 2-7. Elevation Function

5

f. Slide Function. To move the table top toward the foot end of the table, push the SLIDE-FOOT button. See figure 2-8.

To lower the kidney bridge, push the KIDNEYDOWN button. h. Return Function. Pushing the RETURN button will return the table top to a level position from lateral tilt and/or trendelenburg positions. See figure 2-11.

REV. TREND.

SLIDE FOOT END

TREND

TILT LEFT

TILT RIGHT

TABLE UP

TABLE DOWN

SLIDE FOOT

SLIDE HEAD

KIDNEY UP

RETURN

REV. TREND.

TREND

TILT LEFT

TILT RIGHT

TABLE UP

TABLE DOWN

KIDNEY DOWN

SLIDE FOOT

SLIDE HEAD

KIDNEY UP

KIDNEY DOWN

BRAKE UNLOCK

POWER ON

RETURN

RETURN

PRESS TO UNLOCK BRAKES

BRAKE UNLOCK

POWER ON

Figure 2-8. Slide-Foot Function The table top will move longitudinally up to 23-1/2 inches. To return the table top to normal position, push the SLIDE-HEAD button. See figure 2-9.

PRESS TO UNLOCK BRAKES

Figure 2-11. Return Function 2-3. Leg Section

REV. TREND.

For perineal access, the leg section can be easily removed from the table. To remove the section, rotate both locking handles outward and pull the leg section straight out. Reverse the procedure to install the section. See figure 2-12.

TREND

TILT LEFT

TILT RIGHT

TABLE UP

TABLE DOWN

SLIDE FOOT

SLIDE HEAD

KIDNEY UP

KIDNEY DOWN

RETURN

BRAKE UNLOCK

SLIDE HEAD END

POWER ON

PRESS TO UNLOCK BRAKES

Figure 2-9. Slide-Head Function g. Kidney Bridge (Model 3100). To raise the kidney bridge, push the KIDNEY-UP button. See figure 2-10.

REV. TREND.

KIDNEY BRIDGE UP

TREND

TILT LEFT

TILT RIGHT

TABLE UP

TABLE DOWN

SLIDE FOOT

SLIDE HEAD

KIDNEY UP

KIDNEY DOWN

RETURN

KIDNEY BRIDGE DOWN

BRAKE UNLOCK

POWER ON

PRESS TO UNLOCK BRAKES

Figure 2-10. Kidney Bridge-Up Function

6

LOCK HANDLE (2)

Figure 2-12. Leg Section Removal

2-4. X-ray Cassette Tray X-ray cassettes can be inserted into a positionable tray at the head end of the table. See figure 2-13. The cassette can be positioned for x-ray coverage of up to 65 inches from the head end of the table. The removable tray attaches to the drive mechanism with magnets. To position the cassette tray within the table, rotate the manual crank handle located on the side of the table. A positioning guide on the sides of the table corresponds with the travel indicator for precise cassette positioning. Use the positioning guide (if the guide is not visible due to table draping, a measuring tape can be used) to determine the desired location for the cassette. Insert the cassette into the tray and rotate the manual crank until the desired position is achieved on the travel indicator.

CASSETTE TRAY

TRAVEL INDICATOR

HEAD END OF TABLE POSITIONING GUIDE

MANUAL CRANK

Figure 2-13. X-ray Cassette Tray

7

SECTION III MAINTENANCE

3-1. Preventive Maintenance

3-2. Service

The following preventive maintenance checks and services are recommended to ensure the serviceability and proper operation of your SKYTRON surgical table.

Table maintenance can be performed by trained maintenance personnel using SKYTRON authorized replacement parts and service techniques. Service instructions and parts are available from SKYTRON.

a. During normal cleaning, a general visual examination should be made checking for leaks, loose bolts or parts, and cracked, chipped, or missing paint. Any necessary repairs should be made. b. Semi-annually the following checks and services should be performed: 1. Check all hydraulic fittings, mini valves and slave cylinders for proper operation and any signs of leaks. 2. Check the hydraulic speed controls and adjust if necessary. 3. Pressure check (with a gauge) the pressure relief valve. 4. Check all mechanical adjustments and adjust as necessary. 5. Check hydraulic fluid level. 6. Lubricate the slider assembly.

8

To obtain service instructions, replacement parts, factory service or preventive maintenance contracts, contact your nearest SKYTRON representative or write: SKYTRON 5000 36th Street S.E. Grand Rapids, MI 49512 1-800-SKYTRON

5000 36th Street S.E., Grand Rapids, MI 49512 1-800-SKYTRON or 1-616-957-0500 • FAX 1-616-957-5053

12