Smith & Nephew

Dyonics POWER II Control System Operations and Service Manual Rev P

Operations and Service Manual

36 Pages

Preview

Page 1

Glossary of symbols

Follow instructions for use

Caution

Fragile, handle with care

CE mark

General warning sign

Keep Dry

LINK icon

Authorized representative in the European community

Manufacturer

Input/output

Catalog number

Date of manufacture

Atmospheric pressure limitation

Batch code

This way up

Consult instructions for use

Serial number

Fuse rating

TUV certification

1060hPa 500hPa 60°C

Temperature limitation

-20°C

90% T 10A 250V H

Humidity limitation 20%

Type B applied part

EU: Not for general waste

Equipotentiality

Watertight equipment per IEC 60529

Up and down buttons

USB port

On/Off indicator

Oscillate footswitch pedal

Serial interface

Yes

Footswitch window lock

L

Left footswitch pedal

No

Footswitch icon

R

Right footswitch pedal

Forward - clockwise direction of shaver rotation (distal view)

Footswitch icon

Pump icon

Reverse - counterclockwise direction of shaver rotation (distal view)

Drill icon

Saw icon

Oscillate - alternating forward/reverse direction of shaver rotation

Suction on - fluid flow through handpiece unrestricted

Blade window lock - adjustment of cutting window stop position

Blade window lock - blade rotation while setting blade window lock

Suction off - fluid flow through handpiece blocked

Handpiece icon

Lavage start/stop

Prescription Use Only

Unique Device Identifier

Medical Device

Non-sterile

Power Input

Environment-friendly use period.

European Importer

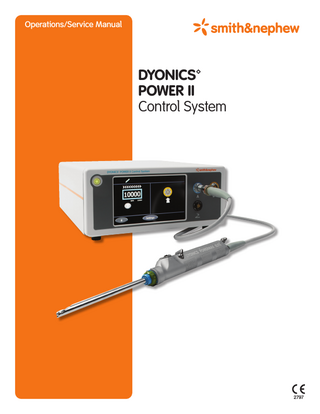

Operations/Service Manual DYONICS™ POWER II Control System

10600181 Rev. P 3

Preface

Preface This manual contains information needed to operate and maintain the Smith & Nephew DYONICS™ POWER II Control System. It is essential that all the information in this manual be read and understood before using or maintaining this system.

Table of Contents Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Device Motor Control... 22

Device Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Suction Control... 22

Intended Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Blade Selection... 23

Intended Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cleaning and Sterilization...25

Indications for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Control Unit... 25

Contraindications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Footswitch... 25

Target Patient Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Handpieces... 25

Expected Clinical Benefit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Service Information... 25

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Replace Rear Panel Fuses... 25

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Adverse Event Reporting...7

Preventive Maintenance... 26

System Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Expected Service Life. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Peripheral Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Handpieces... 8

Observed Problems... 27

Footswitches... 8

Warning Messages... 28

Unpacking and General Inspection . . . . . . . . . . . . . . . . . . . . . . 9

Fault Messages... 29

U.S. Control System (REF 72201030)... 9

Technical Specifications* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

International Control System (Country-specific)... 9

Environmental Conditions... 30

Control and Functions... 10

Ordering Information/Accessories. . . . . . . . . . . . . . . . . . . . . . 31

Control Screen (LCD Layout)... 12

Electromagnetic Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Other Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Recommended System Configuration . . . . . . . . . . . . . . . . . . . 13 Control Unit Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Blade Default Mode versus Blade Recall Mode... 17

Factory Defaults... 30

Guidance for Separation Distances. . . . . . . . . . . . . . . . . . . . . 32 Electromagnetic Immunity...33 Special Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 For Further Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Program Blade Settings... 18 Program Footswitch Settings... 20 Setting Pump Interface... 20 Change System Language... 21 Review System Information... 21

4 10600181 Rev. P

DYONICS™ POWER II Control System Operations/Service Manual

Device Description

Device Description

Intended Use

The Smith & Nephew DYONICS™ POWER II Control System consists of a main control unit and a country-specific power cord. A control system interface cable (optional) and a procedure cart (optional) may also be purchased.

The DYONICS POWER II Control System is intended for use, when used with appropriate procedure-specific blades, for resection of soft and osseous tissues including, but not limited to, use in large articular cavities, and small articular cavities.

The control system provides for variable speed operation of handpieces. The control unit has two instrument ports, allowing for simultaneous use of two handpieces. A footswitch connection port is also available and can be configured to drive the instrument connected to either Port A or Port B. The control unit displays user prompts and system diagnostic text. The control unit can be used with the following: the Smith & Nephew DYONICS 25 Fluid Management System. When the control unit is linked with either pump, the pump outflow regulation occurs, based on whether the blade is in use or idle. A variety of disposable straight and curved surgical blades and burrs can be inserted into the shaver handpiece for various surgical requirements. Blade action can be controlled by either the handpiece or a footswitch, selecting forward, reverse, or oscillate. The control unit provides settings for minimum and maximum blade speeds, preprogrammed for each blade type. This operations/service manual provides information about the DYONICS POWER II Control System and its proper use. For information regarding Smith & Nephew DYONICS Handpieces, refer to the Instructions for Use (REF 10600266). For information regarding the DYONICS Disposable Arthroscopic Blades, refer to Insert (REF 1060595) and Dyonics Handpieces Instructions for Use (REF 10600266). For information regarding the DYONICS 25 Fluid Management System, refer to the operations/service manual (REF 1061600). For information regarding the LINK, refer to the operations/service manual (REF 10601432). For information regarding the DYONICS POWER II Footswitch, refer to the instructions for use (REF 10600267).

Indications for Use The DYONICS POWER II Control System is indicated for use, when used with appropriate procedure-specific blades, for resection of soft and osseous tissues including, but not limited to, use in large articular cavities, and small articular cavities.

Contraindications Smith & Nephew DYONICS Handpieces and Blades should not be used with patients exhibiting ankylosis and also lacking adequate joint space or distention. Abrasion arthroplasty may not be effective in treating heavy patients or those with ankylosis, instability or expectations beyond the relief of pain. Varus or valgus deformity is not itself a contraindication in patients with a good range of motion and without gross instability or extreme malalignment (15° varus, 30° valgus). Intracortical abrasion arthroplasty may be contraindicated in patients who do not qualify for high tibial osteotomy or total knee replacement. Synovectomy is contraindicated when the disease has progressed beyond the phase of synovial proliferation and advanced rheumatoid arthritis, when erosion of the articular cartilage is present.

Target Patient Group The targeted patient population for the DYONICS POWER II Control System is patients requiring surgical procedures as determined to be necessary by the prescribing health care professionals.

Expected Clinical Benefit Facilitate successful resection of soft and osseous tissue.

Intended Users The Smith & Nephew DYONICS™ POWER II Control System is intended for use by health care professionals in accordance with these instructions for use. The use environment is a professional healthcare facility.

Operations/Service Manual DYONICS™ POWER II Control System

10600181 Rev. P 5

Warnings

Warnings • It is the health care professional’s responsibility to be familiar with the appropriate surgical techniques prior to use of this device. • Read these instructions completely prior to use. • The DYONICS™ 25 Fluid Management System and the LINK can be connected to the DYONICS POWER II Control System. The use of non-validated peripheral devices may damage the control unit and create electrical hazards. The use of non-validated peripheral devices will void the warranty. • When connecting peripheral and accessory devices to the DYONICS POWER II Control Unit, use only cables that have been validated for use with the control unit. Non-validated cables may damage the control unit and create electrical hazards. The use of non-validated cables will void the warranty. • Only Smith & Nephew DYONICS Disposable Arthroscopic Blades can be used with the DYONICS POWER II Control System. • DANGER: Risk of explosion if used in the presence of flammable anesthetics. This device is not suitable for use in the presence of a flammable anesthetic mixture with air, oxygen, or nitrous oxide. • To avoid patient burns, do not place the handpiece on the patient when the handpiece is not in use. • High voltage (1500 VAC) is present during dielectric strength testing. Exercise extreme caution while operating the dielectric strength tester to prevent personal injury from electrical shock or damage to the equipment. Ensure that only authorized personnel are in the test area during testing. Ensure that the cover is on the DYONICS POWER II Control Unit before beginning the tests. • Check that the electrical equipment is properly grounded (i.e., plugs contain a ground prong). Grounding reliability can be achieved only when the control unit is connected to an equivalent AC power receptacle marked “hospital only” or “hospital-grade.” • Dangerous voltages are present during leakage current testing. Do not touch the control unit while power is applied. • Do not use this device in oxygen rich environments (>25%). • If this unit is configured as part of a system, the entire system should be tested for compliance with IEC 60601-1.

• The use of accessory equipment not complying with the equivalent safety requirements of this equipment may lead to a reduced level of safety. Consideration relating to the choice of accessory devices shall include: – Use of the accessory in the patient vicinity. – Evidence that the safety certification of the accessory has been performed in accordance with IEC 60601-1. • The use of handpieces, cables, and other accessories, with this equipment, other than those specified or provided by the Smith & Nephew could result in increased electromagnetic emissions or decreased electromagnetic immunity and result in improper operation. • When using a footswitch, ensure that the footswitch is not accidentally activated while inserting the blade or burr, or while plugging the connector cable into the control unit. • Inadvertently depressing a footswitch while plugging in a handpiece will activate the handpiece. • Refer to the DYONICS 25 Fluid Management System Operations/Service Manual (REF 1061600) and LINK Operations/Service Manual (REF 10601432) for the warnings and precautions associated with those devices. • Refer to the Smith & Nephew DYONICS Handpieces Instructions for Use (REF 10600266) for the warnings and precautions associated with the handpieces. • Refer to the Smith & Nephew DYONICS Disposable Arthroscopic Blades Insert (REF 1060595) and DYONICS Handpieces Instructions for Use (REF 10600266) for the warnings and precautions associated with the blades and burrs. • Electrical Interference. This equipment is designed to be used as a stand-alone, in proximity too, or in a stacked configuration with other medical equipment. Although this equipment is designed and tested to minimize interference with, or by, other electrical equipment; interference may occur. If interference occurs with other equipment it may be corrected by one or more of the following measures: – Reorient or relocate this equipment, the other equipment, or both. – Increase the separation between the pieces of equipment. – Connect the pieces of equipment into different outlets or circuits. – Consult a biomedical engineer.

• If the leakage current of the configured system exceeds the limits of IEC 60601-1, install an appropriately rated IEC 60601-1 approved isolation transformer and retest the system. 6 10600181 Rev. P

DYONICS™ POWER II Control System Operations/Service Manual

Precautions

• Abnormal performance, due to Electromagnetic Disturbances, may be manifested by a failure to properly maintain the speed of operation of the hand pieces. If abnormal performance is observed, it may be corrected by one or more of the following measures. – Reorient or relocate this equipment, the other equipment, or both. – Increase the separation between the pieces of equipment. – Connect the pieces of equipment into different outlets or circuits. – Consult a biomedical engineer. • High Frequency (HF) Interference: This equipment was designed and tested to be used with HF Electrical Surgical Unit (ESU) equipment. If interference occurs with other equipment it may be corrected by one or more of the following measures: – Reorient or relocate this equipment, the other equipment, or both. – Increase the separation between the pieces of equipment. – Connect the pieces of equipment into different outlets or circuits. – Consult a biomedical engineer.

Precautions U.S. Federal law restricts this device to sale by or on the order of a physician. • Prior to each use, inspect the device to ensure it is functioning properly and not damaged. Do not use a damaged device. • In all cases, the judgment of the physician (in the best interest of the patient) may take precedence over the procedures described in this manual.

• Environmental Protection: This equipment contains electronic printed circuit assemblies. At the end of the useful life of the equipment it should be disposed of in accordance with any applicable national or institutional policy relating to obsolete electronic equipment. • Do not connect any equipment to the serial port unless it was designed by Smith & Nephew to communicate with the control unit via this port. • Check the Control screen to ensure that the proper settings are displayed prior to beginning any procedure. • Electrical safety testing should be performed by a biomedical engineer or other qualified person. • Excessive risk (leakage current) may result if this equipment is connected to a power distribution system other than the manufacturer’s recommended power distribution system. • This device has been tested and verified to comply with IEC 60601-1-2. This exceeds the requirements specified by FCC Part 18 for ISM equipment. This device is intended for operation in a medical facility only. Usage in a residential environment will likely cause unacceptable RF interference for which the user is held responsible. • Handle the unit with care. If the unit is dropped or damaged in any way, it must be returned immediately for service. • Use only one finger at a time when operating the LCD touch screen. Multiple, simultaneous finger presses can result in unintended changes to settings and erroneous control inputs. • Press the Power Up/Power Down button to turn off the control system. Failure to do so may result in lost custom settings. • Inspect all components regularly for wear. Pay particular attention to potential damage to insulation, especially with universal extension cables. • Do not sterilize or immerse the control unit in disinfectant. • This product contains Nickel (Ni) which may cause allergic reactions

• Use of shaver blades, saw blades, burrs or accessories from a manufacturer or supplier other than Smith & Nephew or its authorized representatives may permanently damage, impede performance, or cause failure of the DYONICS™ POWER II Control System. Use of such products will void the warranty.

Adverse Event Reporting

• Use of reprocessed, single-use shaver blades may permanently damage, impede performance, or cause failure of the DYONICS POWER II Control System. Use of such products will void the warranty.

complaints@smith-nephew.com

If, during the use of this device or as a result of its use, a serious incident has occurred, please report it to the manufacturer and to your national authority.

• To prevent damage to the control unit connector ports, do not plug in wet. Ensure that cleaned or sterilized cable connectors are completely dry prior to connecting to the control unit or handpiece.

Operations/Service Manual DYONICS™ POWER II Control System

10600181 Rev. P 7

System Components

System Components The DYONICS™ POWER II Control Unit includes a Power Up/ Power Down button, an LCD screen, two connection ports for handpieces, a footswitch connection port, and rear panel connections for a variety of peripheral devices. The control unit’s LCD screen displays all of the controls needed to set up and operate the control unit, including adjusting settings, adjusting set speed, selecting oscillation modes, operating window lock, saving settings, and restoring settings to system defaults. The control system has been designed to meet IEC 60601-1 safety and performance standards for medical equipment. The CE mark on the control unit signifies compliance with Regulation (EU) 2017/745.

Peripheral Devices Handpieces A variety of DYONICS handpieces can be used with the control unit. All handpieces can be connected to either the A or B connection port on the control unit front panel (Figure 1). The control unit automatically detects the type of handpiece connected. For information regarding handpieces that may be used with the control unit, refer to the DYONICS Handpieces Instructions for Use. Handpieces are sold separately from the control unit.

DYONICS POWER II Footswitch (REF 72201092) This footswitch communicates switch and pedal action to the control unit. It also supports the DYONICS 25 Fluid Management System’s lavage function and the blade window lock function. The footswitch operation can be modified using the Footswitch settings screen. Two modes are available: On/Off and Variable. Refer to the “Settings” section of this manual for more information. The footswitch has three control pedals and two switches. The pedals are labeled L, R, and <>. The L and R pedals default to reverse and forward, respectively. Depressing the left or right pedal causes the control unit to supply power to the handpiece to drive the blade in the direction indicated. The left and right pedals can be configured to run either forward or reverse. The center (<>) pedal is always oscillate. The two switches provide control for the blade window lock function and the DYONICS 25 Fluid Management System’s lavage function. The footswitch plugs into the footswitch connection port located on the front panel of the control unit (Figure 1). Note: The footswitch does not control the Forward or Reverse Speed Shift settings. The <> (Oscillate) pedal causes the control unit to send alternate forward and reverse commands to the handpiece. The control unit continues the alternating signals until the foot is removed from the <> pedal. For more information regarding the DYONICS POWER II Footswitch, refer to the instructions for use (REF 10600267). For information regarding the DYONICS 25 Fluid Management System, refer to the instructions for use.

Footswitches The control unit can use a wired footswitch to control blade action. Typical footswitches control forward, reverse, oscillate, and window lock modes of operation. A footswitch is required when using the POWERMAX™ ELITE Handpiece (REF 72200617) and the POWERMINI™ Handpiece (REF 72201503) . A footswitch also may be used with the handcontrol handpieces.

8 10600181 Rev. P

DYONICS™ POWER II Control System Operations/Service Manual

Unpacking and General Inspection

DYONICS™ Pedal-Style Footswitch (REF 7205396) The pedal-style footswitch features two foot pedals to control blade action.

Unpacking and General Inspection

This footswitch is comprised only of contact switches. They operate in the On/Off mode, in which each press of the FORWARD or REVERSE pedal starts or stops the handpiece. Press the FORWARD and REVERSE pedals simultaneously for Oscillate mode.

Carefully unpack and inspect all components shipped with the Smith & Nephew DYONICS™ POWER II Control System. If any parts are missing or damaged, contact your authorized Smith & Nephew representative. Save the carton and packing materials in the event a component must be returned for repair. The following parts should have been received:

Smith & Nephew Shaver Interface Cables (optional)

U.S. Control System (REF 72201030)

The DYONICS POWER II Control System is designed for use with the DYONICS 25 Fluid Management System to offer automatic suction control. The DYONICS 25 Shaver Interface Cable (REF 91000973) connects the DYONICS POWER II Control Unit to the DYONICS 25 System Control Unit. Note: The correct cable must be connected if the DYONICS 25 Control Unit automatic suction control feature is to be used.

Smith & Nephew LINK - DYONICS POWER II The LINK – DYONICS POWER II (REF 72205189) enables the DYONICS POWER II to communicate with approved Smith & Nephew devices on the LINK Connect Network.

1 ea Smith & Nephew DYONICS POWER II Control Unit (REF 72200873) 1 ea Smith & Nephew DYONICS 25 Shaver Interface Cable (REF 91000973) 1 ea Hospital-grade power cord (REF 605-0004) 1 ea Smith & Nephew DYONICS POWER II Control System Operations/Service Manual (REF 10600181) 1 ea Smith & Nephew DYONICS Handpieces Instructions for Use (REF 10600266)

International Control System (Country-specific) Each international Smith & Nephew DYONICS POWER II Control System contains the following: 1 ea Smith & Nephew DYONICS POWER II Control Unit (REF 72200873) 1 ea Smith & Nephew DYONICS 25 Shaver Interface Cable (REF 91000973) 1 ea Hospital-grade power cord, country-specific 1 ea Smith & Nephew DYONICS POWER II Control System Operations/Service Manual, country-specific version (REF 10600181) 1 ea Smith & Nephew DYONICS Handpieces Instructions for Use, country-specific version (REF 10600266)

Operations/Service Manual DYONICS™ POWER II Control System

10600181 Rev. P 9

Unpacking and General Inspection

Control and Functions Front Panel

Figure 1. DYONICS ™ POWER II Control Unit Front Panel

Control/Connection

Function

1

Power Up/Power Down Button

Initiates the power up/power down procedures.

2

LCD Touch/Display Screen

Displays system controls, system information, and procedure information. CAUTION: Use only one finger at a time when operating the LCD touch screen. Multiple, simultaneous finger presses can result in unintended changes to settings and erroneous control inputs.

3

Port A

Receptacle for handpiece.

4

Port B

Receptacle for handpiece.

5

Footswitch Connection Port

Receptacle for footswitch.

10 10600181 Rev. P

DYONICS™ POWER II Control System Operations/Service Manual

Unpacking and General Inspection

Rear Panel

T 10A 250V H

2020-07

DYONICS™ POWER II Control Unit

72200873

1

AAX

Endoscopy Smith & Nephew, Inc. 150 Minuteman Road Andover, MA 01810 USA T +1 978 749 1000 • F +1 978 749 1108 Customer Service +1 800 343 5717

2

™ Trademark of Smith & Nephew.

100-240V~, 50/60Hz, 560VA

USA

85002481 Rev. F 01/2021

Figure 2. DYONICS™ POWER II Control Unit Rear Panel (Connectors shown with covers removed) for units with serial numbers AAX-5001 or greater)

Controls/Connections

Function

1

Bidirectional Port 1

Serial communication connection to the LINK.

2

Bidirectional Port 2

Serial communication connection to the DYONICS 25 Fluid Management System.

3

USB Ports (1 and 2)

For authorized service use only.

4

Serial Ports A and B

Not currently used.

5

Bidirectional Port 3

Not currently used.

6

Equipotential Compensator Terminal (case ground)

Used to bring other equipment into the same case potential as the device.

7

Power Cord Connector

This receptacle is an integral part of the power input module and accommodates the hospital grade power cord accessory.

Operations/Service Manual DYONICS™ POWER II Control System

10600181 Rev. P 11

Unpacking and General Inspection

Control Screen (LCD Layout) The Control Screen, LCD layout in Figure 3 provides the user with a visual of the connected devices and the status on the Control Screen during operation. Please see the table below for a description of the functions. Port B

Port A Handpiece icon Pump icon

Drill icon

Footswitch icon

Directional arrows

Directional arrows

Current set speed

Current set speed

Oscillation mode

Unit of measure

Up/ down (increase/ decrease) buttons

Up/ down (increase/ decrease) buttons

Blade window lock button Change mode button

Unit of measure

Setting button

Figure 3. Control screen indicating attachment(s), directional arrows, speed settings, variable control buttons, change mode ( Mode) button, and blade window lock button.

Function

Description

Pump icon

Pump status - Port A appears in blue and Port B appears in yellow.

Handpiece icon

Displayed when a shaver handpiece is connected to either Port A or Port B.

Footswitch icon The footswitch icon indicates a footswitch is connected and assigned to either Port A or Port B. Directional arrows

Forward (>>) Note: If the attached device does not specify a Reverse or Oscillate operation, the direction of the arrows is determined by the attached device. Reverse (<<) Oscillate (<<>>)

Current set speed

Display the current set speed until the footswitch button is released.

Oscillation mode

Forward Reverse Oscillation mode 1 or Oscillation 2 Mode 1 is a based on a time period. Mode 2 is a set number of revolutions. Refer to Table 1 for which handpiece supports the mode of operation.

Unit of measure 12 10600181 Rev. P

The units for the rate of speed: revolutions per minute (RPM), Speed % - Percentage of Maximum speed, or RATE Oscillation Mode 2 rate. DYONICS™ POWER II Control System Operations/Service Manual

Other Indicators

Up (increase) buttons Down (decrease) button

Speed is increased by one increment. Note: Press and hold the Up button to quickly make a large adjustment to set speed. Speed is decreased by one increment. Note: Press and hold the Down button to quickly make a large adjustment to set speed.

Blade Window Lock

Activates Blade Window Lock. This function is available only when the DYONICS POWER II Footswitch is connected.

Change mode

When pressed changes the Oscillation mode between Mode 1 and Mode 2 on Port A or Port B.

Setting

When pressed brings up the Settings screen.

Other Indicators

Recommended System Configuration

Warning Messages

Figure 5 indicates a system configuration that complies with IEC 60601-1 requirements.

If the control unit detects a problem, it displays a yellow warning message box at the bottom of the Port window (Figure 4). Depending on the problem, the system may also beep. Touch the warning message box to open a full description of the error. Press the OK button to close the warning message box and return to the prior screen. A complete list of warning messages is listed in the Warning Message Table.

Fault Messages When the system encounters a system fault, it stops all shaver operation, sounds an audible notification, clears the current screen, and displays the fault message. A complete list of fault messages is listed in the Fault Message Table.

WARNING: If this unit is configured as part of a system, the entire system should be tested for compliance with IEC 60601-1. • If the leakage current of the configured system exceeds the limits of IEC 60601-1, install an appropriately rated IEC 60601-1 approved isolation transformer and retest the system. • The use of accessory equipment not complying with the equivalent safety requirements of this equipment may lead to a reduced level of safety. Consideration relating to the choice of accessory devices shall include: – Use of the accessory in the patient vicinity. – Evidence that the safety certification of the accessory has been performed in accordance with the appropriate IEC 60601-1

Figure 4. Warning message

Operations/Service Manual DYONICS™ POWER II Control System

10600181 Rev. P 13

Control Unit Setup

Wired/Wireless Remote Wired/Wireless RemoteControl Control

Smith & & Nephew Nephew Smith DYONICS™ 25 Fluid Management System DYONICS™ 25 Fluid Management System Control Unit Control Unit REF 7211010 REF 7211010

VAC VAC

RFHandpiece Handpiece RF Wall receptacle

Smith & Nephew VULCAN™ Generator

VAC VAC

Smith & Nephew VULCAN™ Generator REF 7210812 REF 7210812

Wall receptacle 100-240 VAC 100-240 VAC 15 A 15 A 50/60Hz 50/60Hz

Footswitch Footswitch

Handpiece or Handpiece Powered Instrument

Handpiece or Handpiece Powered Instrument Wall receptacle

DYONICS POWER II Shaver System

VAC VAC

DYONICS POWER II Shaver System REF 72200873 REF 72200873

Shaver Shaver Connection Port

Connection Port

Wall receptacle 100-240 VAC 100-240 15 A VAC 15 A 50/60Hz 50/60Hz

Footswitch Footswitch

Figure 5. Recommended configuration for DYONICS™ POWER II Control SystemControl Unit Setup

Control Unit Setup WARNING: The DYONICS™ 25 and the LINK can be connected to the DYONICS POWER II Control System. The use of non-validated peripheral devices may damage the control unit and create electrical hazards. The use of non-validated peripheral devices will void the warranty.

1. Plug the control unit power cord into the rear panel power cord connection port and a grounded AC power source. Note: Accessory devices such as handpieces, pumps, etc. may be plugged into the front and rear panels either before or after powering up the control unit.

WARNING: When connecting peripheral and accessory devices to the DYONICS POWER II Control Unit, use only cables that have been validated for use with the control unit. Non-validated cables may damage the control unit and create electrical hazards. The use of non-validated cables will void the warranty. CAUTION: Use only one finger at a time when operating the LCD touch screen. Multiple, simultaneous finger presses can result in unintended changes to settings and erroneous control inputs. CAUTION: To prevent damage to the control unit connector ports, do not plug in wet. Ensure that cleaned or sterilized cable connectors are completely dry prior to connecting to the control unit or handpiece. 14 10600181 Rev. P

DYONICS™ POWER II Control System Operations/Service Manual

WARNING: Check that the electrical equipment is properly grounded (i.e., plugs contain a ground prong). Grounding reliability can be achieved only when the control unit is connected to an equivalent AC power receptacle marked “hospital only” or “hospital-grade.”

Control Unit Setup

Check the Control screen (Figure 7) to confirm connections and device recognition. The icon for the device connected to Port A appears in the icon bar above the Port A window on the left side of the screen. Icons associated with Port A appear in blue.

2. Press the Power Up/Power Down button to turn the control unit on.

Figure 6. Smith & Nephew splash screen

3. The system will briefly display the Smith & Nephew splash screen (Figure 6) before displaying the Control screen (Figure 7). The Control screen displays connected devices and their status in the Port A and Port B windows. The icon bar across the top of the Control screen displays icons for the pump status, footswitch status, and type of device connected. 4. Connect the device cable to the desired device connection port. A single device can be connected to either Port A or Port B, or two devices can be connected to Port A and Port B respectively. Each port will accept a handpiece. Devices connected to Port A and Port B can be used simultaneously. WARNING: Inadvertently depressing a footswitch while plugging in a handpiece will activate the handpiece.

Figure 7. Control screen

The icon for the device connected to Port B appears in the icon bar above the Port B window on the right side of the screen. Icons associated with Port B appear in yellow. If there is no device connected to a port, the corresponding port window displays a connector icon. 5. Press the Forward button for the device attached to Port A to confirm operation. Press the Forward button for the device attached to Port B to confirm operation. If a device does not have a Forward button, press the equivalent (i.e., a footswitch pedal) to confirm that device’s operation.

Note: Avoid pressing the hand controls while attaching the instrument cable. If this occurs, the instrument will not run until the button is released for one second and then activated.

– When confirming operation, directional arrows immediately above the colored boxes animate and turn green. The directional arrows indicate forward rotation (>>). If the attached device does not specify forward operation, the direction of the arrows is determined by that device.

Note: The system automatically recognizes which type of device is connected to each port.

– The handpiece motor action can be observed inside the distal end of the handpiece.

Note: When a handpiece is connected to the control unit for the first time, the Control screen will display the speed controls for Oscillate Mode 1 for that port. Refer to the “Settings” section of this manual for more information. – Push-on connectors: Handpiece cable connectors have a locking sleeve, which holds a protective cap. Pull the sleeve back to remove the cap. Orient the cable connector plug by aligning the red dots on the plug and the panel. Push the plug into the connection port and release the locking sleeve. The cable is fully engaged when the red dots are aligned.

6. Verify Reverse (<<) and Oscillate (<<>>) modes. The directional arrows indicate Reverse rotation (<<) and Oscillation (<<>>). If the attached device does not specify Reverse or Oscillate operation, the direction of the arrows is determined by that device. 7. Connect the footswitch to the footswitch connection port on the front panel of the control unit. The footswitch connection port is located below the Port A connection port. A black ring designates the footswitch connection port. Check the Control screen to confirm the connection and footswitch recognition. The footswitch icon appears in the icon bar. The footswitch controls the device connected to Port A by default. The footswitch can be set to control the device connected to Port B. Refer to the “Settings” section of this manual for information on adjusting the footswitch settings. 8. Repeat Steps 5 and 6 for the footswitch controls to confirm proper operation of the footswitch-controlled device.

Operations/Service Manual DYONICS™ POWER II Control System

10600181 Rev. P 15

Settings

9. Optional: Connect the suction by sliding the suction tubing onto the outflow portal on the proximal end of the handpiece. 10. Optional: Connect the pump and any other peripheral devices to the appropriate rear panel connection. Refer to the “Rear Panel Layout” section of this manual and the documentation supplied with the device being connected for more information.

Control Unit Integration If the DYONICS™ POWER II Control Unit is connected to a DYONICS 25 Fluid Management System, a pump icon is displayed automatically in the icon bar above the Port A window. The pump defaults to the Port A device. The pump can be set to integrate with the Port B device by selecting the Port B button on the Pump Interface screen located in Settings. Note: A connected pump integrated with Port A responds to commands only from the device and footswitch connected to Port A. A connected pump integrated with Port B responds to commands only from the device and footswitch connected to Port B.

5. Set the shaver suction settings. a. The DYONICS 25 Control Unit shaver suction settings are factory preset to 100% outflow while the handpiece is on and to 50% outflow when the handpiece is idle. Refer to the “Inflow/Outflow Tube Set, Shaver Detected Mode” section of the DYONICS 25 Control Unit Operations/Service Manual for more information. Note: To adjust the DYONICS 25 Control Unit custom shaver suction levels, refer to the “Settings” section of the DYONICS 25 Control Unit Operations/Service Manual for instructions. To integrate the DYONICS POWER II Control Unit with LINK. 1. Ensure the LINK was installed per the LINK MNL (REF 10601432). 2. Ensure the communications cable is connected into the bidirectional port 1 (Figure 2) on the rear panel of the DYONICS POWER II Control Unit.

Notes:

Settings

• The DYONICS POWER II Footswitch lavage start/stop button works only when the footswitch and pump are assigned to the same port.

CAUTION: Use only one finger at a time when operating the LCD touch screen. Multiple simultaneous finger presses can result in unintended changes to settings and erroneous control inputs.

• The DYONICS POWER II Footswitch lavage start/stop button works only with the DYONICS 25 pump.

Once all handpieces and other devices to be used during the procedure have been connected to the control unit and system operation has been verified, press the Settings button at the bottom of the Control screen to view the Settings screen (Figure 8). The Settings button is active whenever the handpieces are not running.

• The pump icon on the Control screen animates only when the control unit is connected to the DYONICS 25 Pump and the pump is pumping. To integrate the DYONICS POWER II Control Unit with a DYONICS 25 Control Unit: 1. Ensure that the fluid management system has been set up per the setup procedures in the Smith & Nephew DYONICS 25 Fluid Management System Operations/Service Manual. 2. Ensure that the communications cable is connected into bidirectional port 2 (Figure 2) on the rear panel of the DYONICS POWER II Control Unit. Note: If the bidirectional port has a cover attached, use a screwdriver to remove the cover before connecting the cable. a. Use the DYONICS 25 Shaver Interface Cable to connect the DYONICS POWER II Control Unit to the DYONICS 25 Control Unit. 3. Connect the shaver interface cable to the fluid management system control unit.

Figure 8. Settings screen

The Settings screen enables users to specify preferences for Oscillate Mode, Footswitch, Pump Interface, and Language. Selecting the System Information button displays system software versions and the System Reset button.

a. For the DYONICS 25 Control Unit, connect the cable to the shaver port on the rear panel of the control unit. 4. Set the suction lever on the handpiece to the MAX (fully open) position.

16 10600181 Rev. P

DYONICS™ POWER II Control System Operations/Service Manual

Settings

The Settings screen enables users to select the blade mode using the Select Blade Default button or the Select Blade Recall button. Footswitch, Pump Interface, and Language settings are automatically saved between each power down and power up. Blade settings are saved only when the control unit is set in Blade Recall mode.

Blade Default Mode versus Blade Recall Mode

The Blade Reset function appears on the Settings screen only if a handpiece is connected to either Port A or Port B. The Blade Reset buttons reset the blade connected to the selected port to the factory default settings. Blade Reset does not change the oscillation mode previously selected for that port.

When in Blade Recall mode, the control unit can be programmed with custom settings for blade forward speed, reverse speed, oscillate speed (Oscillate Mode 1), and oscillate rate (Oscillate Mode 2). If blade settings are changed while the control unit is in Blade Recall, they will be saved until they are changed in Blade Recall or the system is restored to default factory settings (See “Review System Information”).

Press Done to close the Settings screen and return to the Control screen.

The DYONICS™ POWER II Control Unit can be operated in either the Blade Recall mode or the Blade Default mode.

When operating the control unit in Blade Default mode, changes to blade settings will be saved until the control unit is powered down or the system is reset to Blade Recall. Press the Done button to return to the Control screen.

Supported Modes of Operation Handpiece

Maximum (Speed) RPM

Saved Setting

DYONICS POWERMAX™ ELITE (REF 72200616, 72200617, 72200872)

3000

Oscillate Mode 1 (RPM), Oscillate Mode 2 (RATE)

5000

Oscillate Mode 1 (RPM), Oscillate Mode 2 (RATE)

8000

Oscillate Mode 1 (RPM), Oscillate Mode 2 (RATE)

10000

Oscillate Mode 1 (RPM), Oscillate Mode 2 (RATE)

3000

Oscillate Mode 1 (RPM), Oscillate Mode 2 (RATE)

5000

Oscillate Mode 1 (RPM), Oscillate Mode 2 (RATE)

6000

Oscillate Mode 1 (RPM), Oscillate Mode 2 (RATE)

DYONICS POWERMINI™ (REF 72201500, 72201503)

Table 1. Supported Modes of Operation

Operations/Service Manual DYONICS™ POWER II Control System

10600181 Rev. P 17

Settings

Program Blade Settings Press the Settings button to open the Settings screen. To customize and save blade settings, press the Select Blade Recall button on the Settings screen (Figure 9) to set the control unit to the Blade Recall mode. The message in the box above the button changes to read “In Blade Recall” and the selection button name changes to Select Blade Default. Changes made to blade settings while in Blade Recall are saved after the unit is powered down. If the control unit is powered down in Blade Recall, it powers up in Blade Recall, and customized blade settings are retained. The control unit remains in Blade Recall mode until it is reset to Blade Default mode. To change blade settings in Blade Default mode, press the Select Blade Default button on the Settings screen to set the control unit to Blade Default mode. The message box above the button changes to read “In Blade Default” and the selection button name changes to Select Blade Recall. Changes made to blade settings while in Blade Default are not saved after the unit is powered down. If the control unit is powered down in Blade Default, it powers up in Blade Default. Initial blade settings automatically reset to the factory defaults. The control unit remains in Blade Default mode until set to Blade Recall mode.

Setting Oscillate Mode 1 Oscillate Mode 1 is based on a time interval. The time interval determines the length of time it takes for one forward/reverse period of oscillation. Oscillate Mode 1 defaults to a 0.30 second time interval. The time period can be set from 0.30 to 1.0 seconds, in increments of 0.10 seconds. 1. Press the Settings button to open the Settings screen. 2. Press the Oscillate Mode button to open the Oscillate Mode screen (Figure 10). 3. Select the Port A or Port B controls by pressing the Adjust button under the desired port. The settings change only for the port selected. If settings adjustments for both ports are needed, repeat steps 3 and 4 for each port.

Oscillate Mode Settings Oscillation can be based on a desired time period (Mode 1) or a set number of revolutions (Mode 2). Table 1 indicates which handpieces support which modes of operation. All DYONICS™ handpieces support Mode 1 operation. Certain newer devices support Mode 2 operation as well. When the control unit is set to either Blade Default or Blade Recall and a handpiece is connected to Port A or Port B, the Control screen (Figure 10) displays the speed controls for the oscillation mode last used for that port. The directional arrows above the blue or yellow box switch to Oscillate Mode (Figure 10). Use the Up and Down arrows to set the desired speed.

Figure 10. Oscillate Mode screen

4. If the device attached to the selected port can be run only in Mode 1, the Oscillate Mode 1 screen opens (Figure 11). This screen displays the length of time it takes for one forward/ reverse period of oscillation. Use the Up and Down arrows to adjust the oscillation period.

If the handpiece supports both Mode 1 and Mode 2 operation, the Change Mode button is displayed on the Control screen. To view speed controls for the mode not displayed on the Port A or Port B screen, press the Change Mode button for that port (Figure 12).

Figure 11. Oscillate Mode 1 screen

If the device attached to the selected port runs in either Mode 1 or Mode 2, either the Oscillate Mode 1 or the Oscillate Mode 2 screen opens, depending upon which mode was last used for that port. Figure 9. Control screen, Port A, Mode 1 speed control.

18 10600181 Rev. P

DYONICS™ POWER II Control System Operations/Service Manual

Settings

To change from the Oscillate Mode 2 screen to the Oscillate Mode 1 screen: a. Return to the Control screen. b. Press the Mode button at the bottom of the screen (Figure 12). The mode text under the colored box on the Control screen changes to read Mode 1.

4. If the device attached to the selected port runs in either Mode 1 or Mode 2, either the Oscillate Mode 1 or the Oscillate Mode 2 screen (Figure 13) opens, depending upon which mode was last used for that port.

c. Press the Settings button to return to the Settings screen. d. Press the Oscillate Mode button to return to the Oscillate Mode screen. e. Press the Oscillate Mode Adjust button to access the Oscillate Mode 1 screen.

Figure 13. Oscillate Mode 2 screen

To change from the Oscillate Mode 1 screen to the Oscillate Mode 2 screen: a. Return to the Control screen (Figure 7). b. Press the appropriate Mode button at the bottom of the screen (Figure 12). The mode text under the colored box on the Control screen changes to read Mode 2. Figure 12.

Mode buttons on the Control screen

5. On the Oscillate Mode 1 screen, use the Up and Down arrows to adjust the oscillation period. The oscillation period can be set from 0.30 to 1.0 seconds, in increments of 0.10 seconds. 6. Press the Set button to save the setting and return to the Oscillate Mode screen. Press the Cancel button to return to the Oscillate Mode screen without saving changes. Press the Restore Default button to restore factory default settings for the attached device.

Setting Oscillate Mode 2 Oscillate Mode 2 is based on the number of revolutions a blade completes before reversing direction. The Oscillate Mode 2 revolutions can be set at 1 or 2 revolutions. Oscillate Mode 2 defaults to 2 revolutions. 1. Press the Settings button on the Control screen (Figure 7) to open the Settings screen. 2. Press the Oscillate Mode button to open the Oscillate Mode screen (Figure 10).

Note: If the device connected does not support Mode 2 operation, the Mode button does not appear on the Control screen. c. Press the Settings button to return to the Settings screen. d. Press the Oscillate Mode button to return to the Oscillate Mode screen. e. Press the Oscillate Mode Adjust button to access the Oscillate Mode 2 screen. 5. On the Oscillate Mode 2 screen, use the Up and Down arrows to adjust the number of revolutions the blade completes in one direction before reversing during oscillation. The number of revolutions per period cannot be set lower than 1 or higher than 2. 6. Press the Set button to save the setting and return to the Oscillate Mode screen. Press the Cancel button to return to the Oscillate Mode screen without saving changes. Press the Restore Default button to restore factory default settings for the attached device.

3. Select the Port A or Port B controls by pressing the Adjust button under the appropriate port. The settings change only for the selected port. If settings adjustments for both ports are needed, repeat steps 4 and 5 for each port.

Operations/Service Manual DYONICS™ POWER II Control System

10600181 Rev. P 19

Settings

Program Footswitch Settings The Footswitch (Figure 14) screen provides controls for assigning the footswitch to either Port A or Port B, enabling the Hand Control Override feature, setting the footswitch Mode, and changing the forward and reverse pedal assignments. Note: The footswitch lavage function is available only when the DYONICS™ POWER II Footswitch and the DYONICS 25 Fluid Management System are connected. Note: The footswitch Blade Window Lock function is available only when the DYONICS POWER II Footswitch is connected. 1. Press the Footswitch button on the Settings screen to open the Footswitch screen (Figure 14). If the control unit detects a DYONICS POWER II Footswitch it can operate in either Variable or On/Off mode. If the control unit detects a Pedal-Style footswitch, the Mode buttons will not appear on the screen, and the footswitch will operate in On/Off mode only.

4. Use the Hand Control Override buttons to set the primary controls for a connected device. The green button indicates the current Hand Control Override setting. When the Hand Control Override is set to On, only the footswitch operates the handpiece. The hand controls for that handpiece do not operate. When the Hand Control Override is set to Off, either the hand controls or the footswitch can be used to operate the device. However, only one source of control can be used at one time. The handpiece controls and the footswitch cannot be used simultaneously. 5. Use the Forward buttons to assign forward action to the left or right pedal on the DYONICS ™ POWER II Footswitch. The Forward option appears only when the system detects the footswitch. 6. Press Set to save the footswitch settings and return to the Settings screen. Press Cancel to return to the Settings screen without saving any changes.

Setting Pump Interface Press the Pump Interface button on the Settings screen to open the Pump Interface screen (Figure 15). The pump interface operates only for the handpiece connected to the port to which the pump is assigned. For example, Port A must be selected in the Port Control box for the pump to work with the handpiece connected to Port A.

Figure 14. Footswitch screen for analog footswitch (Mode buttons available)

2. With an analog footswitch such as the DYONICS POWER II Footswitch use the Mode buttons to select either the On/Off or Variable Mode. The green button indicates the current Mode setting. The On/Off mode button sets the footswitch pedals to digital switch operation. Depressing the pedal causes the handpiece to operate at full set speed. Releasing the pedal turns the handpiece off. The Variable mode button sets the footswitch pedals to adjust the handpiece speed based on pedal pressure. 3. Use the Port Control buttons to assign the footswitch to a preferred port. Press the Port A or Port B button to assign the footswitch to either Port A or Port B. The green button indicates the current Port Control setting. The footswitch drives the device connected to the selected port.

20 10600181 Rev. P

Figure 15. Pump Interface screen

1. Press the Pump Interface button on the Settings screen to open the Pump Interface screen. 2. Press the Port A button in the Port Control box to assign the pump interface to Port A. Press the Port B button in the Port Control box to assign the pump interface to Port B. The green button indicates the Pump Interface setting. 3. Press Set to save the Pump Interface setting to memory and return to the Settings screen. Press the Cancel button to return to the Settings screen without making any changes.

DYONICS™ POWER II Control System Operations/Service Manual

Settings

Change System Language

Review System Information

Press the Settings button to open the Settings screen. Press the Language button to open the Language screen (Figure 16).

Press the Settings button on the Control screen to open the Settings screen. Press the System Information button to open the System Information screen (Figure 18). The System Information screen displays the product name, product reference number, software version, application version, and motor controller version. If a DYONICS™ POWER II Footswitch is connected to the control unit, this screen displays the footswitch software version. If the DYONICS POWERMINI™ Handpiece is connected to the control unit, this screen displays the handpiece software version.

Figure 16. Language screen

Select the desired language by pressing the corresponding button. The control unit displays a confirmation message “Are you sure that you want to change the displayed language to {selected language}?” in that language (Figure 17). Press the button to confirm and change the control unit language. To cancel and leave the control unit language unchanged, press the x button. Press the Done button to return to the Settings screen.

Press the System Reset button to reset all system settings, including blade settings, to the original factory default settings. The selected language does not change. When the System Reset button is pressed, a confirmation screen asking “Are you sure you want to reset all saved settings?” is displayed (Figure 19). Press Yes to return the system to the factory default settings. Press No to return to the System Information screen without making any changes. Refer to the “Technical Specifications” section of this manual for system default settings. Note: Applies to system Serial Numbers above 5001.

Figure 18. System Information screen Figure 17. Language Selection pop-up

Figure 19. System Reset prompt

Operations/Service Manual DYONICS™ POWER II Control System

10600181 Rev. P 21

Operation

Operation

DYONICS™ POWER II Footswitch

CAUTION: Use only one finger at a time when operating the LCD touch screen. Multiple, simultaneous finger presses can result in unintended changes to settings and erroneous control inputs.

The Smith & Nephew DYONICS POWER II Footswitch operation can be modified using the Footswitch screen. Refer to the “Footswitch Settings” section of this manual for more information.

Adjustable speed control buttons for the handpiece connected to Port A appear below the blue box on the left side of the screen. The blue box color corresponds to the blue ring on the Port A connector. During operation, use these Up and Down buttons to adjust handpiece speed. Changes take effect immediately. If no device is connected to Port A, a cable connector icon is displayed in the blue box.

The left, right and oscillate pedals each vary set speed between 0–100%, depending upon the pressure applied to the pedal. Maximum pressure provides 100% of set speed. Zero pressure stops the device.

Adjustable speed controls for the handpiece connected to Port B appear in the yellow box on the right side of the screen. The yellow box color corresponds to the yellow ring on the Port B connector. During operation, use these Up and Down buttons to adjust handpiece speed. Changes take effect immediately. If no device is connected to Port B, a cable connector icon is displayed in the yellow box.

In addition, the DYONICS POWER II Footswitch provides button controls for lavage and blade window lock. For more information regarding the DYONICS POWER II Footswitch, refer to the Instructions for Use for that product.

DYONICS Pedal-Style Footswitch With the pedal-style footswitch, depressing the FORWARD or REVERSE pedal starts the handpiece. Releasing the pedal stops the handpiece. Press the FORWARD and REVERSE pedals simultaneously for Oscillate mode.

Device Motor Control

Suction Control

Device motors can be operated using either the device controls or footswitch controls. A device with hand controls allows the surgeon to control shaver operation without the need for a footswitch.

The suction flow control lever on the distal end of the handpiece enables manual suction control. The lever can be set anywhere between the fully open and fully closed positions. For more information about shaver handpieces, refer to the Smith & Nephew DYONICS Handpieces Instructions for Use.

To activate the handpiece using the hand controls, press and release the Forward, Reverse or Oscillate button. The device operates in the selected mode until any button is pressed and released again, which stops the motor. Press and release the desired button to restart or change direction. Note: If a footswitch is assigned to the same port as the handpiece, ensure that the hand control override setting on the Footswitch screen is set to Off. To activate a no-hand controls handpiece, ensure that the footswitch is assigned to the same port as the handpiece. If a handpiece without hand controls is connected to a port without a footswitch assigned, a warning message is displayed on the screen for that port. The message disappears when a footswitch is connected. The button or pedal controls on the footswitch allow selection of three cutting actions: Forward, Reverse, and Oscillate. Note: On the three-pedal footswitches, if the Forward and Oscillate pedals are depressed simultaneously, the Oscillate pedal takes priority. If the Reverse and Oscillate pedals are depressed simultaneously, the Oscillate pedal takes priority.

22 10600181 Rev. P

DYONICS™ POWER II Control System Operations/Service Manual