Smith & Nephew

VULCAN Generator Operations Service Manual Rev A

Operations Service Manual

36 Pages

Preview

Page 1

Operations/Service Manual

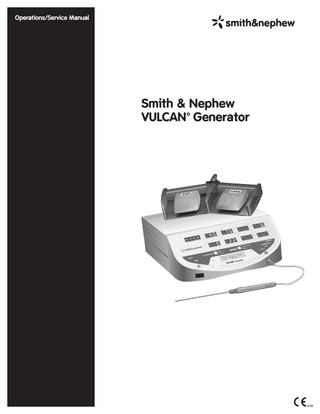

Smith & Nephew VULCAN™ Generator

Glossary of Symbols

Non-Sterile

Fuse

CAUTION: See Instructions for Use

Amplitude Control

Dangerous Voltage: Danger of electric shock

ON

CAUTION: U.S. Federal law restricts this device to sale by or on the order of a physician.

OFF

Fragile; handle with care

Up and Down buttons

This Way Up

Temperature Range

Keep Dry

Humidity

Neutral (return) Electrode

Catalog Number

Defibrillator Proof Type BF Equipment

Serial Number

Equipotentiality

Date of Manufacture

Alternating Current

European Representative

Non-ionizing Electromagnetic Radiation

CE Mark

Protective Earth (ground)

UL Classification

Footswitch

EU: Not for general waste

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

1061526 Rev. A

1

Preface / Table of Contents

Preface This manual provides the information you need to operate and maintain the Smith & Nephew VULCAN™ Generator as part of the ELECTROTHERMAL™ Arthroscopy System (EAS™). It is essential that you read and understand all the information in this manual and on the generator label before using or maintaining the equipment.

Table of Contents Glossary of Symbols...1 Preface...2 Introduction Device Description...3 How Supplied...3 Indications for Use...3 Contraindications...3 Warnings...4 Precautions...5 Adverse Reactions...5 Controls and Functions Front Panel Layout...6–7 Rear Panel Layout...8 Preoperative Setup...9 Operation Operational Modes...10 Power Delivery Modes...10 Controls and Functions...11–12 Instructions for Use...12–13 Cleaning and Sterilization...14 Service and Maintenance Service Philosophy...15 Electrical Interference...15 Environmental Protection...15 Replacing Fuses...15 Software Upgrades...16 Replacing/Returning Worn or Defective Equipment or Parts...16 Preventative Maintenance...16 Calibration of Temperature Measurement Circuit...16

2

1061526 Rev. A

Troubleshooting Generator Control Unit...17 Alarm and Fault Messages...17–20 Observed Problems...21–23 Technical Specifications...24 Ordering Information...25 Output Charts Output Voltage vs. Output Control...26 Power Output vs. Output Control, Cut Mode...26 Power Output vs. Output Control, Coag Mode...27 Power Output vs. Load Resistance...27 Guidance and Manufacturer’s Declaration Electromagnetic Emissions...28 Electromagnetic Immunity...29–30 Guidance for Separation Distances...31 Warranty...Back Cover Service Replacement Units Warranty...Back Cover Service Replacement Program...Back Cover Repair Service Program...Back Cover Figures 1 Control unit front panel...6 2 Control unit rear panel...8 3 AC receptacle with fuses...15

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

Introduction

As part of the Smith & Nephew ELECTROTHERMAL™ Arthroscopy System (EAS™), the Smith & Nephew VULCAN™ Generator is designed to provide finelycontrolled radiofrequency (RF) energy for the coagulation, cutting, ablation and hemostasis of soft tissue during a variety of surgical procedures. The generator control unit is specifically designed for use with Smith & Nephew temperature-controlled and cutting/ablation probes. Temperature and impedance monitoring assist the surgeon by automatically adjusting energy delivery to maintain effective tissue heating during temperature-controlled applications.

How Supplied The Smith & Nephew VULCAN Generator (REF 7210812) is supplied NON-STERILE. The Smith & Nephew VULCAN Footswitch (REF 7209692), hospital-grade power cord and Operations/Service Manual are included with the Smith & Nephew VULCAN Generator. The Smith & Nephew VULCAN Extension Cable (REF 7209693) is available as an accessory for use with probes that do not include an integrated cable.

Indications for Use

Device Description The generator control unit is a line-voltage powered, radiofrequency generator capable of delivering up to 200 watts of power. The generator control unit includes a neutral electrode monitor (NEM™) to monitor split grounding pad contact quality. It is designed to be used only with Smith & Nephew temperature-controlled, cutting, and ablation probes and includes the following features: • Two RF output modes: Temperature Control Mode, where the output power is softwarecontrolled to maintain a specified tissue temperature; and Power Control Mode, used for cutting/ablation and hemostasis. • Numerical displays for impedance, set power, delivered power, set temperature, actual temperature, set cut, set coagulation, preset selections and set blend.

The Smith & Nephew VULCAN Generator is indicated for general surgical purposes, including orthopedic and arthroscopic applications, for coagulation, ablation, and hemostasis of soft tissues, in combination with Smith & Nephew temperaturecontrolled, cutting, and ablation probes.

Contraindications There are no known absolute contraindications to the use of electrosurgery. The use of the Smith & Nephew VULCAN Generator and accessories is contraindicated, when, in the judgment of the physician, an electrosurgical procedure would be contrary to the best interests of the patient.

• Message display for text messages. • Indicators for electrode type (monopolar or bipolar), mode (Temperature Control or Power Control), stand-by, RF power on, RF output type (cut or coagulation), fault, and neutral electrode monitoring. NEM continuously monitors the neutral electrode grounding pad connection during surgery, discontinuing RF delivery if a fault in the NEM monitor circuit is detected. • A probe recognition system: the generator control unit automatically selects the appropriate mode and preset settings for the probe type. The Smith & Nephew VULCAN Generator software can be upgraded at the customer’s location with a Smith & Nephew supplied PCMCIA card. An authorized Smith & Nephew representative will perform the software upgrade.

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

1061526 Rev. A

3

Warnings

Warnings • It is the surgeon’s responsibility to be familiar with the appropriate surgical techniques prior to use of this device. • Read these instructions completely prior to use. Failure to do so may result in patient or staff injury. • DANGER–Risk of explosion if used in the presence of flammable anesthetics, skin preparation agents, or biointestinal gases. • Hazardous electrical output. This equipment should be used only by qualified medical personnel trained in the use of electrosurgery devices. • This device has been tested and verified to comply with the IEC 60601-2-2 (2001). This exceeds the requirements specified by FCC part 18 for ISM equipment. This device is intended for operation in a medical facility only. Usage in a residential environment will likely cause unacceptable RF interference for which the user is held responsible. • The generator control unit must be powered from a properly grounded 120–240 VAC, single-phase supply. Excessive risk (leakage current) may result if this equipment is connected to other than the manufacturer's recommended power distribution system. • RISK OF BURNS OR FIRE. Do not use near conductive materials such as metal bed parts, inner-spring mattresses, etc. • Check that the electrical equipment is properly grounded (i.e. plugs contain a ground prong). The generator control unit must be plugged into a hospital-grade AC outlet. • Safe use of monopolar electrosurgery demands proper grounding of the patient and proper insulation between the patient and any metal surfaces. A split grounding pad with a surface area of at least 20 square inches (130 cm 2) is required. Valleylab T REM T pads meet this dimensional requirement and may be ordered through Smith & Nephew (REF 7209687). • Improper pad selection, improper pad placement, or improper probe usage may result in patient burns at the return pad. To avoid this, follow the manufacturer's Instructions for Use.

4

1061526 Rev. A

• Failure of the radiofrequency surgical equipment could result in unintended increase of output power. • Burns to the surgeon’s hands may be possible if a probe comes into contact with a metal instrument or surface. • Use of electrosurgery in patients with internal or external pacemakers, implantable defibrillators or monitoring equipment may require special considerations. The attending cardiologist and/or the pacemaker manufacturer should be consulted prior to surgery. • During monopolar electrosurgery the patient should not come into contact with any metal parts which are grounded or which have appreciable capacitance to earth (operating tables, supports, etc.). The use of anti-static sheeting is recommended for this purpose. • During monopolar electrosurgery skin-to-skin contact (i.e., between the arms and body of the patient) should be avoided. Insertion of dry gauze or its equivalent is recommended. • The probe cables and extension cable should be positioned in such a way that contact with the patient or other leads is avoided. Probes not in use should be stored isolated from the patient. • Incorrect actual temperature readings may result in improper treatment. Verify that the TEMPERATURE display reads the expected value (room temperature or body temperature) prior to treatment. If the TEMPERATURE reading is not accurate, check the device and connectors for damage, moisture, or contamination. Clean or replace as needed. • If desired tissue effect is not being achieved, do not increase power beyond the normal range without first inspecting the integrity of the probe and neutral (return) electrode. • To prevent electric shock, unplug the control unit from the electrical outlet before attempting to replace the fuses. • To avoid fire hazard, use only fuses of the correct type, voltage rating, and current rating. • To prevent electric shock, do not remove the control unit cover. There are no userserviceable components inside. Dismantling the equipment will void the warranty. Refer servicing to qualified Smith & Nephew personnel.

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

Precautions / Adverse Reactions

Precautions U.S. Federal law restricts this device to sale by or on the order of a physician. • Prior to use, inspect the product package for signs of damage or tampering. If damaged, do not use. • Prior to use, examine the device(s) for possible damage to assure proper functioning. If damaged, do not use. • The Smith & Nephew VULCAN™ Generator is designed specifically for use only with Smith & Nephew arthroscopic radiofrequency probes. Do not use other devices with the generator control unit. • Check the probe and extension cable connections for the presence of liquid before use or whenever a probe is connected or disconnected during a procedure. Liquid may enter the connection during a procedure. ANY liquid can cause the connections to short, resulting in erroneous probe recognition or damage to the probe, cable or generator control unit. • Check the generator control unit’s LCD message display to ensure that the proper probe identification and settings are displayed prior to beginning any procedure. • Use the lowest RF power setting necessary to achieve the desired tissue effect. • This equipment is designed and tested to minimize interference with other electrical equipment. However, if interference occurs with other equipment it may be corrected by one or more of the following measures: Reorient or relocate this equipment, the other equipment, or both. Increase the separation between the pieces of equipment.

• Inspect all components, including extension cables and power cord, regularly for wear. Pay particular attention to extension cable insulation. Replace if evidence of deterioration is noted. • Use only Smith & Nephew arthroscopic RF probes with the Smith & Nephew VULCAN Generator. Do not use other devices with the generator control unit. • Apparent low output or failure of the generator control unit to function properly at normal operating settings may indicate faulty application of the neutral (return) electrode. • Grounding reliability can only be achieved when the generator control unit is connected to an equivalent AC power receptacle marked “hospital only” or “hospital–grade.” • When the generator control unit is used simultaneously with physiological monitoring equipment on the same patient, any monitoring electrodes should be placed as far from the surgical electrodes as possible. Needle monitoring electrodes are not recommended. Monitoring systems using high frequency currentlimiting devices are recommended. • Use only the power cord and connector specified for this unit. • Electrical safety testing should be performed by a biomedical engineer or other qualified person.

Adverse Reactions • Fire • Explosion • Burns • Electric shock • Patient and/or staff injury

Connect the pieces of equipment into different outlets or circuits. Consult a biomedical engineer. • This equipment contains electronic printed circuit assemblies. At the end of the useful life of the equipment it should be disposed of in accordance with any applicable national or institutional related policy relating to obsolete electronic equipment.

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

1061526 Rev. A

5

Controls and Functions

Front Panel Layout

Figure 1. Control unit front panel

Impedance Display IMPEDANCE displays the impedance in ohms, measured at the tip of the probe. Active in both Temperature Control and Power Control Modes. Set Power Display with Up/Down Arrows SET POWER displays the maximum probe power output in watts, increased or decreased using the SET POWER up/down arrows. Active only in Temperature Control Mode.

Preset Display with Up/Down Arrows PRESET displays the preset temperature and/or power combination chosen and is adjustable using the PRESET up/down arrows. Settings are displayed as 1, 2, 3, etc. Active in Temperature Control and Power Control Modes. Actual Power Display ACTUAL PWR displays the actual power in watts delivered to the probe. Active only in Temperature Control Mode.

Set Temperature Display and Up/Down Arrows SET TEMP displays the target tissue temperature in degrees Celsius (° C), increased or decreased using the SET TEMP up/down arrows. Active only in Temperature Control Mode. Set Cut Display with Up/Down Arrows SET CUT displays the maximum probe power output in watts, increased or decreased using the SET CUT up/down arrows. Active only in Power Control Mode.

6

1061526 Rev. A

Actual Temperature Display TEMPERATURE displays the actual temperature in degrees Celsius (° C), measured at the tip of the probe. Active only in Temperature Control Mode. Set Coag Display with Up/Down Arrows SET COAG displays the maximum probe power output in watts, increased or decreased using the SET COAG up/down arrows. Active only in Power Control Mode.

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

Controls and Functions (continued)

Front Panel Layout (continued) Set Blend Display with Up/Down Arrows SET BLEND displays the blend combination, selected using the SET BLEND up/down arrows. Active only in Power Control Mode. Fault Indicator (Red Light)

Coag Indicator (Blue Light) COAG illuminates when the generator control unit is delivering RF power and when the blue COAG (right) footswitch is pressed. Cut Indicator (Yellow Light)

FAULT illuminates when a fault condition is detected. NEM™ Indicator (Green or Red Lights) NEM illuminates with a green light when the NEM circuit is correctly connected and with a red light when the NEM circuit is incorrectly connected. NEM will only illuminate when a monopolar probe is being used.

CUT illuminates when the generator control unit is delivering RF power and when the yellow CUT (left) footswitch is pressed. RF Power On Indicator (Green Light) RF POWER ON illuminates when the generator control unit is delivering RF power. Stand-By Indicator (Green Light)

Bi/Monopolar Button The BI/MONOPOLAR button selects the appropriate RF energy mode (monopolar or bipolar). The generator selects the appropriate mode automatically based on the probe type. Bi/Monopolar Indicator Either MONO (monopolar) or BIPOLAR is illuminated to identify the appropriate probe type. Mode Button The MODE button selects the appropriate RF energy delivery mode (Temperature Control or Power Control). Mode Indicator

STAND-BY illuminates when the generator control unit is in Stand-By Mode. Neutral (Return) Electrode Connector Accepts a dual–pin connector specifically designed for neutral electrode monitoring (NEM). Message Display Displays modes, probe type, alarms, warnings, or fault messages. Probe Connector Accepts 8-pin Smith & Nephew probes. The Smith & Nephew VULCAN™ Extension Cable (REF 7209693) may be used with the generator control unit.

Either TEMPERATURE (Temperature Control Mode) or POWER (Power Control Mode) is illuminated to identify the appropriate generator mode.

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

1061526 Rev. A

7

Controls and Functions (continued)

Rear Panel Layout

Figure 2. Control unit rear panel

Footswitch Connector Accommodates the generator footswitch cable supplied with the Smith & Nephew VULCAN™ Generator.

Power Cord Connector The power cord connector is part of the power input module, and accommodates the hospital-grade power cord supplied with the Smith & Nephew VULCAN Generator.

Volume Control This knob adjusts the volume of the energy delivery tone. Fan Outlet Carrying Handle Equipotential Compensator Terminal This terminal can be used to bring other equipment to the same case potential as the generator control unit.

8

1061526 Rev. A

Fuse Access Door The fuse access door is part of the power input module. See the “Replacing Fuses” section for instructions on fuse replacement. To avoid hazards, use appropriate fuses as specified in the “Technical Specifications” section. On/Off Switch Rocker-type main power switch.

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

Preoperative Setup

WARNINGS: • DANGER–Risk of explosion if used in the presence of flammable anesthetics, skin preparation agents, or biointestinal gases. • Hazardous electrical output. This equipment should be used only by qualified medical personnel trained in the use of electrosurgery devices. • This device has been tested and verified to comply with the IEC 60601-2-2 (2001). This exceeds the requirements specified by FCC part 18 for ISM equipment. This device is intended for operation in a medical facility only. Usage in a residential environment will likely cause unacceptable RF interference for which the user is held responsible. • The generator control unit must be powered from a properly grounded 120–240 VAC, single-phase supply. Excessive risk (leakage current) may result if this equipment is connected to other than the manufacturer's recommended power distribution system. • RISK OF BURNS OR FIRE. Do not use near conductive materials such as metal bed parts, inner-spring mattresses, etc. 1. Plug the power cord into the rear panel power cord connector and a grounded AC power source. WARNING: Check that the electrical equipment is properly grounded (i.e., plugs contain a ground prong). The generator control unit must be plugged into a hospital-grade AC outlet.

4. Affix the split grounding pad to the patient according to the instructions found in the pad packaging. Select a well-vascularized application site in close proximity to the surgical site. Avoid bony or hairy prominences. Shave, clean, and dry the application site as needed. Apply the pad firmly, assuring full adhesion and contact with the patient’s skin. After the pad is properly applied to the patient, connect the pad to the NEM connector on the control unit front panel. Note: It is important that the split grounding pad be connected to the generator control unit after the pad is properly placed on the patient. This allows the generator control unit to determine an accurate baseline split grounding pad contact quality measurement for a particular patient and will allow the system the greatest resolution in determining if a loss of split grounding pad contact occurs during the procedure. WARNING: Safe use of monopolar electrosurgery demands proper grounding of the patient and proper insulation between the patient and any metal surfaces. A split grounding pad with a surface area of at least 20 square inches (130 cm 2) is required. Valleylab REM pads meet this dimensional requirement and may be ordered through Smith & Nephew (REF 7209687). WARNING: Improper pad selection, improper pad placement, or improper probe usage may result in patient burns at the return pad. To avoid this, follow the manufacturer's Instructions for Use.

2. Inspect the footswitch for any obvious defects. Connect the footswitch cable to the appropriate connector on the rear of the generator control unit. 3. Prepare the patient using standard technique for electrosurgical procedures. The patient’s entire body, including extremities, must be insulated against contact with grounded metal parts. The operating table itself should be grounded, and sufficient layers of electrically insulating sheets should be placed underneath the patient. A waterproof cover should be placed over the insulating sheets, with absorbent sheets placed between the patient and the waterproof cover to absorb any moisture.

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

1061526 Rev. A

9

Operation

Operational Modes

Power Delivery Modes

Power Up

Temperature Control Mode

When the AC power to the generator control unit is turned on using the power switch on the rear panel, the generator performs a series of system self-tests to determine if it is performing properly. The selftests include:

If the MODE button is pressed once while the generator is in Stand-By Mode or if a temperature controlled probe is connected to the generator, the generator will enter the Temperature Control Mode. In Temperature Control Mode, the Smith & Nephew VULCAN™ Generator software automatically adjusts energy delivery to maintain the tissue temperature indicated in the SET TEMP display. Only monopolar temperature-controlled probes may be used in Temperature Control Mode.

ROM checksum RAM test Temperature measurement calibration test RF system test Display segments and indicators test If any of the system self-tests fail, the FAULT indicator on the front panel is illuminated and a continuous tone sounds. Contact Smith & Nephew if any system self-test fails. WARNING: Failure of the radiofrequency surgical equipment could result in unintended increase of output power.

Stand-By Mode Immediately after performing the Self-Test, the generator will default to Stand-By Mode. All of the displays on the front panel will be blanked, and the generator control unit will not be able to deliver RF power while it is in Stand-By Mode.

Fault Mode If a fault is detected at any time during the generator control unit’s operation, the FAULT indicator light will illuminate, an alarm will sound, an error code and text message will be displayed in the message display, and the generator will enter the Fault Mode. RF energy cannot be delivered and the control unit must be powered down then powered up again to exit from Fault Mode.

10

1061526 Rev. A

All Smith & Nephew probes are equipped with a sensor that enables the generator control unit to detect the type of probe connected. When a probe is connected, the Smith & Nephew VULCAN Generator software will read the sensor and automatically adjust power output and temperature parameters to the pre-programmed PRESET settings for the probe type. If a probe is not detected, the generator control unit will default to PRESET “1”, and the SET POWER and SET TEMP displays will show the power and temperature values corresponding to this setting. Either SET POWER or SET TEMP may be changed from their default values.

Power Control Mode (Cutting and Ablation) The generator enters Power Control Mode if the MODE button is pressed once while the unit is in Temperature Control Mode, or twice while in Stand-By Mode, or if a cutting or ablation probe is connected to the control unit. The user may change the type and amount of power delivered by adjusting SET CUT, SET COAG, or SET BLEND levels.

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

Operation (continued)

Controls and Functions Set Power SET POWER may be changed by pressing the up/down arrows located next to the SET POWER display. Power may be adjusted from 1–50 watts. Pressing the appropriate button repeatedly will adjust the power in increments of 1 watt; holding the button down will scroll through the power settings automatically.

Set Temperature SET TEMP may be changed by pressing the up/down arrows located next to the SET TEMP display. Temperature may be set from 15–99° C. Pressing the appropriate button repeatedly will adjust the temperature in increments of 1° C; holding the button down will scroll through the temperature settings automatically.

Set Cut SET CUT may be adjusted by pressing the up/down arrows located next to the SET CUT display. Power may be adjusted from 1–200 watts or up to the preprogrammed limit for the probe type used. Pressing the appropriate button repeatedly will adjust the power in increments of 5 watts; holding the button down will scroll through the power settings automatically.

Preset (Temperature Control Mode) Commonly used temperature and power combinations are pre-programmed into the Smith & Nephew VULCAN™ Generator software to allow the operator to quickly configure the generator control unit in Temperature Control Mode. Use the PRESET up/down arrows on the control unit front panel to select the desired setting. The selected setting will be displayed in the front panel PRESET display, and the corresponding temperature and power settings will be displayed in the SET TEMP and SET POWER displays.

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

Preset (Power Control Mode) The preset values for some probes cannot be changed. However, SET CUT and/or SET COAG can be individually adjusted for these probes. Commonly used SET CUT and SET COAG power combinations are pre-programmed into the generator software to allow the operator to quickly configure the control unit in Power Control Mode. Use the PRESET up/down arrows on the control unit front panel to select the desired setting. The selected setting will be displayed in the PRESET display and the corresponding power settings will be displayed in the SET CUT and SET COAG displays.

Set Coag SET COAG may be adjusted by pressing the up/down arrows located next to the SET COAG display. Power may be adjusted from 1–200 watts or up to the pre-programmed limit for the probe type used. Pressing the appropriate button repeatedly will adjust the power in increments of 5 watts; holding the button down will scroll through the power settings automatically.

Set Blend SET BLEND allows the user to select from four different power combinations for use in the Power Control Mode. These combinations are created by changing the amplitude of the control unit voltage at different time intervals. The amplitudes are derived from the SET CUT and SET COAG settings. For example, in Blend 3, the average power is [(0.75) SET CUT + (0.25) SET COAG]. Blend 0

Blend 1

Blend 2

Blend 3

CUT

100%

25%

50%

75%

COAG

0%

75%

50%

25%

1061526 Rev. A

11

Operation (continued)

Auto Probe Recognition

Footswitch Connector

The Smith & Nephew VULCAN™ Generator software recognizes which type of Smith & Nephew probe is connected to the control unit by reading a sensor in the probe. When a probe is connected to the control unit, the software automatically switches to the appropriate power output MODE and PRESET setting for that specific probe. If a probe is not detected, the generator control unit will default to SET CUT “65” and SET COAG “45”. SET BLEND will display “0”.

A dual, electrically-activated footswitch is provided to control RF energy delivery. The blue COAG (right) pedal is used with temperature-controlled probes and with SET COAG in Power Control Mode. The yellow CUT (left) pedal is used with cutting/ablation probes in Power Control Mode.

The SET TEMP and SET POWER settings may be changed from their preset values using the up/down arrows next to the SET TEMP and SET POWER displays. The Smith & Nephew VULCAN Generator software also contains maximum temperature and power limits for each temperature-controlled probe type. The SET TEMP and SET POWER settings cannot be set to values higher than the maximum programmed in the software. This feature ensures that each probe type is used within its safe limits of operation.

Energy Delivery Tone A tone sounds whenever RF energy is delivered. Volume is adjustable using the volume control knob on the control unit rear panel. In Power Control Mode the tone is a steady sound while RF energy is delivered. In Temperature Control Mode the tone sounds slowly while probe temperature is increasing. The tone sounds more rapidly as the set temperature is approached. The tone is rapid and steady when the set temperature is reached and while it is held. Any variation in tone speed signals the user that the probe temperature is not at the target temperature.

Fault Tone The fault tone sounds briefly during generator control unit startup, and in the event of a warning or fault condition. The volume of the fault tone cannot be adjusted by the user.

12

1061526 Rev. A

Temperature Control Mode Yellow CUT pedal – inactive Blue COAG pedal – enables coagulation output with temperature control

Power Control Mode Yellow CUT pedal – enables cut output Blue COAG pedal - enables coagulation output

Instructions for Use 1. Turn the control unit on using the on/off switch on the rear panel. The generator will perform a series of system self-tests to determine if it is performing properly. If any of these tests fail, the FAULT indicator will illuminate and a continuous tone will sound. Contact Smith & Nephew Customer Service if any system self-test fails. Inspect the front panel displays for any system indicator warnings or messages. After completing the self-tests, the generator will default to Stand-By Mode. All the displays on the front panel will be blank and the generator will not be able to deliver RF power. 2. Connect the selected Smith & Nephew probe to the probe connector on the control unit front panel. If the probe includes an integrated cable, insert the cable connector with the thumb groove up. For probes without an integrated cable, connect the probe to the extension cable. An audible “click” may be heard. Tug gently on the extension cable to ensure proper connection. Connect the other end of the probe cable into the probe connector.

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

Operation (continued)

3. Verify that the selected probe’s name is presented on the message display. The generator software will recognize the probe type by reading a sensor in the probe and will automatically switch to the appropriate power output, MODE, and PRESET setting for that specific probe. WARNING: Burns to the surgeon’s hands may be possible if a probe comes into contact with a metal instrument or surface. CAUTION: Check the probe and extension cable connections for the presence of liquid before use or whenever a probe is connected or disconnected during a procedure. Liquid may enter the connection during a procedure. ANY liquid can cause the connections to short, resulting in erroneous probe recognition or damage to the probe, cable, or generator control unit. CAUTION: Check the generator control unit’s LCD message display to ensure that the proper probe identification and settings are displayed prior to beginning any procedure. 4. Confirm that the NEM™ light is illuminated green. If illuminated red, check the neutral electrode to assure full adhesion and contact with the patient's skin. 5. If using a temperature-controlled probe, proceed to step 6. If using a power-controlled probe, skip steps 6–8 and proceed directly to step 9. 6. For temperature-controlled probes, check the temperature display to confirm expected values. WARNING: Incorrect actual temperature readings may result in improper treatment. Verify that the TEMPERATURE display reads the expected value (room temperature or body temperature) prior to treatment. If the TEMPERATURE reading is not accurate, check the device and connectors for damage, moisture, or contamination. Clean or replace as needed.

7. To begin RF energy delivery, depress and hold the blue COAG footswitch for the type of power to be delivered, according to the probe's instructions for use. The green RF POWER ON and blue COAG indicator lights will illuminate. WARNING: If desired tissue effect is not being achieved, do not increase power beyond the normal range without first inspecting the integrity of the probe and neutral (return) electrode. 8. During energy delivery, the generator sounds a fluctuating tone. The tone pulsates slowly while probe temperature is ramping up to the SET TEMP. The tone will sound more rapidly as the SET TEMP is approached. The tone is rapid and steady when the SET TEMP is reached and while it is held. Any variation in tone speed signals the user that probe temperature is not at the target temperature. 9. To begin RF energy delivery in the Power Control Mode, depress and hold the selected footswitch for the type of power to be delivered, according to the probe's instructions for use. Select the yellow CUT pedal for the cut output and the blue COAG pedal for the coagulation output. The green RF POWER ON and yellow CUT or blue COAG indicator lights will illuminate. Note: During energy delivery in the Power Control Mode, a steady tone will sound while RF energy is being delivered. Different tones are generated for CUT and COAG. 10. Maintain pressure on the footswitch as long as energy delivery is desired. 11. RF energy delivery may be discontinued at any time by releasing the footswitch. To resume RF energy delivery, press and hold the footswitch again.

CAUTION: Use the lowest RF power settings necessary to achieve the desired tissue effect.

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

1061526 Rev. A

13

Cleaning and Sterilization

Generator Control Unit To clean the exterior of the generator control unit: • Disconnect the generator control unit from the ground AC wall receptacle. • Wipe with any liquid antiseptic solution. Nonflammable solution should be used. Take care not to allow any liquid to pass into any electrical connections or into the interior of the generator control unit.

• Prepare a solution of commercially available manual cleaner (i.e., Manu-klenz T) according to the manufacturer’s instructions. Gently scrub the cable using a soft, non-metallic brush while the cable is immersed in the cleaning solution. • Rinse the cable thoroughly under warm running tap water for one minute. • Dry the devices with a soft, clean cloth. • Autoclave using the following parameters:

• Let the surfaces dry thoroughly before plugging the generator control unit back into the wall receptacle.

– Dry time: No dry time needed.

DO NOT steam sterilize the generator control unit. DO NOT immerse the generator control unit in glutaraldehyde or other liquid sterilant or disinfectant. DO NOT submerge the generator control unit for any reason.

– Flash gravity: Ten minutes steam exposure at 131.5–133.5° C (target=132° C).

Smith & Nephew VULCAN™ Extension Cable The Smith & Nephew VULCAN Extension Cable (REF 7209693) is reusable and may be cleaned and sterilized as follows: • Rinse the cable with warm running tap water for a minimum of two minutes or until all visible debris is removed. • Place the cable in a bath containing Klenzyme T (enzymatic detergent), prepared according to the manufacturer’s instructions, for two minutes. Make sure that there is sufficient detergent to cover the cable.

– Pre-vac: Four minutes steam exposure at 132–135° C.

Note: Cables may be individually wrapped in surgical kraft paper and then placed in individual sterilization pouches prior to pre-vac sterilization.

Footswitch The footswitch may be wiped down with any liquid disinfecting solution; non-flammable solution should be used. DO NOT immerse the footswitch cable.

Probes Smith & Nephew probes are disposable and are intended for SINGLE-USE ONLY. Do not attempt to clean or resterilize any Smith & Nephew probe.

• Rinse the cable thoroughly under warm running tap water for one minute.

14

1061526 Rev. A

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

Service and Maintenance

Service Philosophy

Replacing Fuses

There are no user-serviceable components inside the generator control unit. Repairs and adjustments are to be performed only by Smith & Nephew authorized service centers.

WARNING: To prevent electric shock, unplug the control unit from the electrical outlet before attempting to replace the fuses.

If service becomes necessary, call your authorized Smith & Nephew Customer Service Representative prior to returning the device and request a Return Authorization (RA) number. Your representative can also explain the available Service Replacement and Repair Programs. Service items should be carefully repackaged and returned post-paid to Smith & Nephew. Your Smith & Nephew Customer Service Representative can provide additional instructions. Note: Product returned that is found to have been serviced by an unauthorized third party repair facility and/or sterilized with a sterilization method other than one approved by Smith & Nephew will incur additional costs, regardless of warranty status.

WARNING: To avoid fire hazard, use only fuses of the correct type, voltage rating, and current rating. Note: Fuses that require frequent replacement may indicate an internal problem with the control unit. If fuses continue to blow, contact Smith & Nephew Customer Service for assistance.

To Inspect and/or Replace Fuses 1. Unplug the power cord from the power outlet and from the control unit. 2. Use a screwdriver to open the fuse compartment door on the AC receptacle (Figure 3) and slide out the two fuse carriers. Refer to the “Rear Panel Layout” section to locate the AC receptacle on the rear panel.

It is not necessary to include accessory items (i.e., power cords, footswitches, etc.) when returning a device for service.

3. Replace fuses. See “Technical Specifications” section for replacement fuse types.

Electrical Interference

4. Re-insert the fuse carriers using the arrows on the inside of the fuse compartment door as a guide.

CAUTION: This equipment is designed and tested to minimize interference with other electrical equipment. However, if interference occurs with other equipment it may be corrected by one or more of the following measures:

5. Snap the fuse compartment door closed.

Reorient or relocate this equipment, the other equipment, or both. Increase the separation between the pieces of equipment. Connect the pieces of equipment into different outlets or circuits.

Fuse

Consult a biomedical engineer.

Environmental Protection CAUTION: This equipment contains electronic printed circuit assemblies. At the end of the useful life of the equipment it should be disposed of in accordance with any applicable national or institutional related policy relating to obsolete electronic equipment.

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

ON/OFF Switch Fuse Carrier

Figure 3. AC receptacle with fuses

1061526 Rev. A

15

Service and Maintenance (continued)

Software Upgrades A security door on the bottom of the generator control unit allows access to the PCMCIA card for software upgrades. Only a trained Smith & Nephew representative should upgrade the Smith & Nephew VULCAN™ Generator software.

Replacing/Returning Worn or Defective Equipment or Parts

Calibration of Temperature Measurement Circuit There is no method for the user to alter the calibration of the temperature measurement hardware in the field. However, Smith & Nephew recommends that this calibration be checked on an annual basis. If it is found to be out of specification, the device should be returned to Smith & Nephew for repair.

Other than fuses, the Smith & Nephew VULCAN Generator has no customer-serviceable parts. For service, please contact your representative or Smith & Nephew Customer Service.

The generator performs a self-test during power-up to verify power calibration. There is an internal, 100 ohm resistor which is measured and compared to its specified value. The generator goes into a Fault Mode if the calibration is out of specification. In addition, the thermocouple amplifying circuits are checked for calibration. However, there is no check on the “absolute” temperature measured by a temperature probe; therefore, this calibration must be manually checked.

Preventative Maintenance

Equipment

The following inspections should be performed on an annual basis to ensure safe operation of the Smith & Nephew VULCAN Generator.

• Thermometer

Contact Smith & Nephew Customer Service to order replacement footswitches, extension cables, or any other accessory, and for instructions on disinfection and return of worn-out or defective equipment or parts.

Inspection of Cables Inspect the power cable and replace if signs of wear or abrasion are visible.

Inspection of Connectors Inspect all connectors on the control unit for signs of wear or damage. Look specifically for bent or damaged pins, loose fittings, etc. Contact Smith & Nephew Customer Service for assistance if any damage is detected.

• TAC™-S probe with connecting cable • Beaker

Procedure 1. Fill the beaker with cool water (10–30° C). 2. Use the thermometer to measure and record the temperature of the cooled water. 3. Turn on the control unit and connect the cable of the test TAC-S probe. Verify that the control unit goes into the Temperature Control Mode. The TEMPERATURE should display room temperature. 4. Immerse the tip of the TAC-S probe in the water and record the actual temperature. 5. Repeat steps 1–4 using hot water (50–90° C). The TEMPERATURE reading with the TAC-S probe should be +/- 3° C of the thermometer reading in both cases. If a greater difference is observed, contact Smith & Nephew for assistance.

16

1061526 Rev. A

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

Troubleshooting

Generator Control Unit

Alarm and Fault Messages

The generator control unit includes a message display that provides a text description of any alarm or fault messages. If the system is not operating as expected, check the message display.

The generator detects two types of error conditions: alarms and faults.

WARNING: To prevent electric shock, do not remove the control unit cover. There are no user-serviceable components inside. Dismantling the equipment will void the warranty. Refer servicing to qualified Smith & Nephew personnel.

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

An alarm is generated to inform the user that the output of the device is being disabled to prevent injury to the patient or damage to the device. Alarms are automatically cleared once the alarm condition returns to its acceptable value. A fault is a more serious error condition and typically occurs as a result of a hardware failure, such as a stuck footswitch or a conversion circuit that is out of calibration. The FAULT indicator light will be illuminated, and requires that the control unit be reset by cycling power. Refer to the troubleshooting techniques for those faults that can be corrected by the user. If a fault other than those listed occurs, contact Smith & Nephew for assistance.

1061526 Rev. A

17

Troubleshooting (continued)

Alarm and Fault Messages (continued) Type Alarm

Alarm

Alarm

Alarm

Alarm

Message

Condition

OPEN TC- RF disabled RF output is not allowed in in Temp Control mode the Temperature Control Mode unless a valid (Note: “OPEN TC" refers to an temperature measurement is open thermocouple circuit.) returned from the probe’s temperature sensor.

Possible Remedy • Check probe connection to generator control unit. • Replace probe.

Cannot use CUT pedal RF output is disabled in the Use COAG pedal. in Temp Control mode Temperature Control Mode if the yellow CUT footswitch is pressed. RF Disabled - Check Return Electrode

RF output is disabled in any monopolar mode if the impedance between the electrodes on the return electrode is greater than the calculated threshold.

LOW LOAD IMPEDANCE- RF output is reduced to Output power reduced below 5 watts whenever the measured load impedance is less than 40 ohms (or 20 ohms depending on the probe). NEM CIRCUIT SHORTED- If the impedance calculated Use split-pad return during NEM initialization is less than 5 ohms, the unit indicates a NEM contact failure.

Check that the return electrode is properly applied to the patient and that the cable is properly connected to the generator control unit. Keep active electrode away from metallic surfaces during use.

• Check that split grounding pad is being used. • Check that the neutral electrode is properly applied to the patient and that the pad is properly connected to the front of the control unit. • To test for proper operation of the NEM circuitry, unplug the neutral electrode and connect a 100 ohm, noninductive resistor across the two pins of the neutral electrode connector. The Impedance should be sufficiently high to clear the alarm. If the alarm persists, contact Smith & Nephew.*

*Call Smith & Nephew Technical Support at 1-800-343-5717 in the U.S., or your local Smith & Nephew representative.

18

1061526 Rev. A

Smith & Nephew VULCAN™ Generator

Operations/Service Manual

Troubleshooting (continued)

Alarm and Fault Messages (continued) Type

Message

Alarm

POWER FACTOR LOW Output power reduced

Alarm

Can't use COAG pedal with this probe

Alarm

RF Disabled - No Probe Detected

Alarm

Cannot use Temp Cont Probe in Power Mode

Fault

CJC Out of Range

Fault

Footswitch Stuck On

Smith & Nephew VULCAN™ Generator

Condition

Possible Remedy

RF output is reduced to below Keep active electrode away 5 watts whenever the from metallic surfaces during calculated power factor is use. less than 0.2. The use of the COAG pedal is not supported with the connected probe.

Use the CUT pedal.

A footswitch was pressed when no probe was connected.

Connect a probe prior to pressing a footswitch.

A thermocouple was detected on a probe.

Use the Temperature Control Mode.

The cold-junction Let generator reach room compensator (CJC) portion of temperature. the thermocouple circuit has detected a room temperature outside the expected range of 10–35° C. This may occur if the control unit was exposed to extreme temperatures. One or both footswitches was activated during start-up.

Operations/Service Manual

• Check each footswitch to make sure a cord or other object is not interfering with the footswitch connection. • Reset the control unit by turning it off and then back on again.

1061526 Rev. A

19