Smiths Medical

Level 1 Model H-1000 Operators and Service Manual Rev 001 Aug 2006

Operators and Service Manual

31 Pages

Preview

Page 1

OPERATOR’S AND SERVICE MANUAL

-

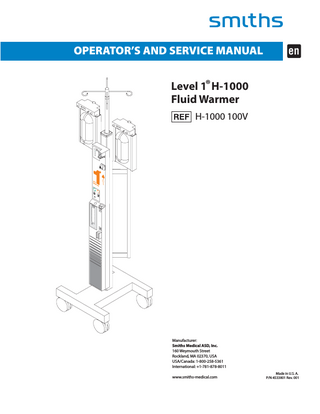

Level 1® H-1000 Fluid Warmer H-1000 100V

Manufacturer: Smiths Medical ASD, Inc. 160 Weymouth Street Rockland, MA 02370, USA USA/Canada: 1-800-258-5361 International: +1-781-878-8011 www.smiths-medical.com

Made in U.S. A. P/N 4533801 Rev. 001

Level 1® H-1000 Operator's & Service Manual About This Manual Purpose Concept System Features Filter with Gas Vent Temperature Control Flanking I.V. Pole Brackets Unpacking and Set up System 1000 Hardware Power and Alarm Test Panel Display Panel Interlocks Accessories: System 1025 Pressure Infusers Set-up and Use Disposables: Set up and Performance Setting Up Disposable Sets Priming Disposable Sets Filter with Gas Vent Replacement in IV Disposable Sets Trouble Shooting Trouble Shooting Slow Flow Rates Testing Add Water Alarm Check Disposables Alarm Water Over Temperature Alarm Alarm Testing Performance Testing Earth Leakage Ground Continuity Dialectric Strength Maintenance Maintenance and Testing Log Service Warranty Service Non-Warranty Service Specifications Physical Specifications Electrical and Environmental Specifications Accessory, Maintenance and Calibration Part Numbers Parts and Electrical Schematics International Symbols

2 2 2 3 3 4 4 4 6 6 7 8 9 9 12 12 13 13 15 16 17 17 17 18 18 18 19 19 20 20 22 22 22 24 24 24 24 25 25 28

No part of this manual may be reproduced in any form without prior written permission from Smiths Medical ASD, Inc. (Smiths Medical) Level 1 and Smiths design mark are trademarks of the Smiths Medical family of companies. The symbol ® indicates the trademark is registered in the U.S. Patent and Trademark office and certain other countries. *Cover pictures the H-1025, a combination of the H-1000 Fluid Warmer and two accessory H-2 Pressure Infusion Chambers. The products described are covered by one or more of the following U.S. Patent Nos. 4,759,749; 4,878,537; 4,900,308; 5,063,994; 5,097,898; and 4,678,460; other patent(s) pending. © 2006 Smiths Medical family of companies. All rights reserved. Operator’s Manual Part #4533801 (Rev 001) 2006/08

About This Manual These instructions contain important information for safe use of the product. Read the entire operator's manual, including Warnings and Cautions, before using the Level 1® H-1000 Fluid Warmer. Failure to properly follow warnings, cautions, and instructions could result in death or serious injury to the patient.

! WARNING ! Messages that are headed by "! WARNING !" indicate information or procedures that if not followed correctly can cause improper results, damage to the equipment, injury to personnel, or patient death. Messages that are headed by "CAUTION:" indicate information or procedures that if not followed correctly can cause improper results and damage to the equipment. Messages that are headed by "NOTE:" indicate information or procedures that if not followed correctly can cause improper results.

Purpose The Level 1® H-1000 fluid warmer has been designed for safe, rapid in-line warming of I.V. fluids as they are administered to patients. Disposable sets designed for warming at various infusion rates are available. Blood and I.V. solutions may be infused through the Level 1® I.V. Sets, and will be delivered near 40 °C. High flow capacity, warm fluid delivery, simple operation, and continuous on-board safety systems make the H-1000 the ideal choice for all procedures requiring routine to rapid infusion of normothermic fluids. Typical uses of the system include blood and solution warming during elective surgery, in the I.C.U., the Emergency Room and in Trauma.

Concept The H-1000 fluid warmer consists of a reusable hardware device and a single-use disposable set. Similar to extracorporeal warming technology found in the heart room, warmed water is rapidly circulated through a disposable anodized aluminum tube to warm fluids as they are delivered to the patient. The use of a thermal conductor, rapid warm water circulation, and counter-current flow all contribute to the high warming capacity of the H-1000.

2

Circulating water bath flow

Heat Exchanger

Heater

Pump Figure 1. Block diagram of Level 1® fluid warmers.

Figure 1 diagrams the H-1000 and its operation. An onboard pump circulates warm water through the aluminum heat exchanger in the disposable set. Note that the circulating water bath and the infusate flow against each other, or countercurrent, which maximizes heat transfer. This diagram describes the essence of all Level 1® fluid warmers.

System features Filter with Gas Vent Level 1® D-Series Disposable Sets employ a unique "hands-off" Gas Vent which vents micro-bubbles of gas that are always released from fluids as they are warmed. In many other warming systems, these micro-bubbles are actually delivered to the patient along with the warmed fluids. The Filter with Gas Vent assembly in the I.V. Sets contains a 170-micron screen filter to trap macro-aggregates found in blood products. This filter has luer-lock connections and

3

can be easily changed without patient disconnection or repriming of the entire disposable set. The Filter with Gas Vent should be changed every three hours or when the filter becomes clogged, whichever comes first. Temperature control The H-1000 employs a safe circulating water heating system, inherently free of any "hot spots." The primary temperature control circuit sets the circulating water bath to a temperature of approximately 42 °C for efficient heat exchange and maximum fluid warming. Flanking I.V. Pole Brackets The sturdy design of the H-1000 offers a compact, custom I.V. pole mount set up. This versatile workstation features flanking side poles for Level 1® pressure infusers, syringe pumps or infusion pumps.

Unpacking and Set up The H-1000 packaging should contain the following items: Quantity

Contents H-1000 Warming Unit H-1000 I.V. Pole Base H-1000 I.V. Bag Hanger H-1000 I.V. Pole with Flanking Brackets

1 1 1 1

Accessory Pack: H-1000 Manual D-Series Instruction Card Y-Connector Black Pneumatic Tubing Hex Wrench

1 1 1 1 1

1. Place the base upright on its wheels. Lock casters to prevent pole movement during set up. 2. Remove the three threaded pole screws on the vertical base tube. Slide the I.V. pole with flanking brackets down over the vertical base tube lining up the three screw holes in the pole with the three screw holes in the base as shown in Figure 2. Note: the flanking brackets should face the longer side of the base. 3. Thread the three pole screws back through the holes at the base of the pole and tighten. 4. Attach the H-1000 warming unit to the flanking brackets by sliding the eight threaded screws on the back of the unit into the eight keyhole notches on the flanking I.V. pole brackets. (Refer to Figure 2.) Tighten all eight screws to secure warmer to I.V. pole and flanking brackets. 5. Lock I.V. bag hanger into place on the top of the I.V. pole.

4

6. Close the drain valve (seen in Figure 7) on the bottom of the unit. Remove the fill port plug on the front of the unit and fill the tank with 1.4 liters of distilled water. Replace the fill port plug.

Figure 2. H-1000 assembly CAUTION: Tap water will increase earth leakage current. For proper system operation and component life, use only DISTILLED WATER in the water reservoir. 7. Plug the unit into the appropriate electrical outlet. (See specifications for details. )

5

CAUTION: This device must be assembled and tested by Smiths Medical technical personnel, an authorized distributor of Smiths Medical or a trained biomedical engineer prior to placing the device into service. Refer to the Testing section of this manual for complete system testing instruction.

H-1000 Hardware The H-1000 has an onboard water supply heated to 41.7 °C. This temperature controlled water supply is rapidly circulated through the heat exchanger of the disposable set. Two independent circuits continuously control and monitor water temperature, and will shut the system down and alarm in the event of an over temperature condition. Power and Alarm Testing The power and alarm test panel on the front of the H-1000 cabinet is shown in Figure 3 below. It contains four membrane switches. Only a gentle press is required to activate each switch.

1. POWER ON The green switch on the left powers ON the H-1000 warming unit including the onboard compressor for the pressure infuser accessory system.

2. POWER OFF The orange switch on the right powers OFF the unit.

3. ALARM TEST This alarm test button confirms proper operation of visual and audible alarm systems. Press and hold this button to test alarm systems. When the switch is released the WATER OVER TEMPERATURE alarm will continue to sound. This is normal operation. To clear the alarm condition, turn the unit OFF and then back ON.

4. OVER TEMPERATURE TEST This alarm test button confirms proper operation of the OVER TEMPERATURE circuitry.

6

Press and hold this button to test this alarm circuitry. When the switch is released the WATER OVER TEMPERATURE alarm will continue to sound. This is normal operation. To clear this alarm condition, turn the unit OFF and then back ON. Figure 3. Power and Alarm Panel

Figure 4. Display Panel

41

1.4 Liters H2O

Display Panel The display panel shown in Figure 4 contains visual information that continuously indicates the status of the H-1000 during operation. Five displays provide information for safe, convenient use of the device.

1. CIRCULATING WATER BATH TEMPERATURE Displays temperature of the circulating water bath in °C. This is not the temperature of the fluid delivered to the patient.

2. SYSTEM OPERATIONAL This GREEN indicator illuminates when the power switch is ON and the heat exchanger has been properly installed.

7

3. CHECK DISPOSABLES This Yellow indicator and pulsing AUDIBLE ALARM indicate the heat exchanger is NOT properly installed.

4. ADD WATER This Yellow indicator and pulsing AUDIBLE ALARM indicate additional distilled water must be added to the water reservoir.

5. WATER OVER TEMPERATURE This RED indicator and AUDIBLE ALARM indicate an over temperature condition. Press and hold this switch to confirm proper operation of the OVER TEMP circuitry. NOTE: When any one or more of the alarms are activated, and the red and/or yellow indicators are illuminated, and the audible alarm is sounding, no water is circulating and no fluid warming is taking place. Interlocks Three low voltage interlocks are located in the cabinet. They sense the presence of a properly installed heat exchanger and filter with gas vent. These interlocks prevent the pump from pumping water when there is no disposable in place to complete the circulation loop. If the "CHECK DISPOSABLE" alarm is activated and the light next to the "2" socket is illuminated, press the #2 socket down firmly to engage the interlock switch. The H-1000 display panel provides information for safe, convenient set up and use of the device.

8

Accessories: H-1025 Pressure Infusers The H-1000 is equipped with an onboard compressor that is used to operate two Level 1® pressure infusion chambers (H-2’s). Pressure Infusion chambers are sold separately as an accessory to the H-1000. The H-1000 combined with two pressure infusion chambers is referred to as the H-1025. Pressure Infusers are not required to operate the H-1000, but are a valuable accessory to complete this total fluid management system. H-1025 pressure infusers provide controlled, convenient pressurization of I.V. blood and fluid bags for rapid administration of fluids. These automated pressure chambers quickly reach and hold a preset pressure of 300 mmHg for high speed fluid delivery not possible with manually pumped pressure cuffs. The factory set 300 mmHg pressure is constant and not adjustable. At 300 mmHG pressure, flow rates may be altered by adjusting the roller clamp on the Level 1® D-series disposable I.V. fluid warming set. With the H-1025 infusion chambers, pressure can be applied or released with the throw of a switch. Empty I.V. fluid bags can be de-pressurized, replaced and repressurized in seconds. Each pressure infuser contains an expansion bladder to accommodate either a 500 ml bag or a 1000 ml bag. And a safety relief valve is also contained in each chamber to help prevent over-pressurizing fluid bags. If you have purchased a pair of pressure infusion chambers, please refer to the following pressure infuser set up instructions for proper installation. Packaging for each pair of H-1025 pressure infusers should contain the following items: Contents

Quantity

H-2 Pressure Infuser Y-Connector Black Tubing

2 1 1

Set-up and Use CAUTION: This device must be assembled and tested by Smiths Medical technical personnel, an authorized distributor of Smiths Medical or a trained biomedical engineer prior to placing the device in service. ! WARNING !: Level 1® pressure chambers are to be used only as a component of the Level 1® fluid warmer. Do not connect to compressed gas bottles, O.R. Air, or any other pneumatic pressure source. Be sure that the chrome poles on the H-1000 are in the upright position. 1. Loosen the two pole mounting thumb screws on the back of one H-2 pressure chamber as seen in Figure 5. Slide the H-2 over the top of the flanking bracket.

9

2. Secure the H-2 in place by tightening the two pole mounting screws. 3. Repeat steps 1 and 2 for the second H-2 pressure chamber. 4. Remove the orange plug from the red ring connector located on the back of the H-1000. This is done by depressing the red plastic ring and pulling the plug out.

Mounting Screws

Chrome Pole

5. Press the piece of black pneumatic tubing firmly into the connector on the back of the H1000 until it bottoms out. Press the other end of the tubing into bottom of the Y-connector.

Y-Connector

Remove Plug and insert black tubing

Figure 5. Installing Pressure Infusers

6. Press the black tube from one of the H-2s into the Y-connector. Press the black tube from the other H-2 into the Yconnector.

Once the H-1000 is turned on, 300 mmHg pressure can be automatically applied by pushing the toggle switch on the top front of the H-2 chamber all the way over to the "+" or ON position. Always make sure that the chamber door is closed and latched when pressure is activated. With the Level 1® pressure infusion chambers properly installed, the H-1000 fluid warmer becomes the H-1025, a complete fluid management system.

10

To Load In order to help avoid inadvertent infusion of air to the patient the following warnings should be observed:

! WARNING ! Remove all air from solution bags.

! WARNING ! Not for use with commercial I.V. solution bags less than 1 liter with air.

! WARNING ! Not for use with autotransfusion bags. 1. Set up and prime Level 1® D-Series disposable I.V. fluid warming set following the instructions on disposable package. 2. Flip toggle switch on top front of the H-2 chamber all the way over to the "-" or OFF position. 3. Open chamber door by swinging out hinged latch on right side. 4. Hang air-free solution bag on door post. NOTE: Each pressure chamber can hold either a 500 ml bag or a 1000 ml bag. For a 500 ml bag, the hanging post is located on the inside of the door. For a 1000 ml bag, the post is located on the top of the door. For optimum drainage of 1 liter bags, the upper molded post is for longer style bags. The lower molded post is used for standard size bags. 5. Close door and secure side latch. To Pressurize CAUTION: Be certain latch is secure before chamber is pressurized. Never pressurize with door open. CAUTION: Do not exceed 300 mmHg. 1. Push toggle switch all the way over to "+" or ON position. Observe pressure gauge to ensure 300 mmHg (approx.) is achieved. NOTE: The pressure is not adjustable on this device. The fluid warmer power switch must be ON for pressure chambers to operate. To Unload 1. Push toggle switch all the way over to the "-" or OFF position. This will release pressure in the chamber and deflate bladder. 2. Open door and remove fluid bag.

11

NOTE: Chamber pressure must be released before the pressure chamber door can be opened. To Clean Please refer to the maintenance section of this manual for complete cleaning and disinfecting procedures for the H-1025 pressure infusers.

Disposables: Set up and Performance

! WARNING ! Refer to D-series disposable packaging for complete set up and priming instructions, indications, contraindications, warnings, cautions and additional product information. Setting Up Disposable Sets Level 1® D-series disposable sets have been designed to be highly effective and easy to use in combination with the H-1000 fluid warming hardware. By following the simple 1-2-3 blocks found on the H-1000 fluid warmer, properly trained users can confidently have the system safely set up and operating within seconds. Following the numbers found on the H-1000: 1. Push the bottom end of the heat exchanger into the bottom heat exchanger #1 socket. Be sure the heat exchanger is fully seated.

! WARNING ! Do not bend heat exchanger. Bending the heat exchanger may damage the inner aluminum tube. If the tube is bent, serious patient injury or death could result. 2. Slide the top (#2) socket up. Snap the heat exchanger into the heat exchanger guide. Be sure it is fully seated. Slide the top heat exchanger socket down over the heat exchanger tube. 3. Insert the Filter with Gas Vent into the #3 holder on the front of the cabinet. 4. Press the green power switch on the front of the cabinet to turn ON the unit and allow it to reach operating temperature while the disposable set is being primed. It takes between 3 and 7 minutes for the water in the H-1000 to reach operating temperature.

12

When the H-1000 is plugged in and turned ON and the disposable set is correctly installed, a green"OPERATING" light will illuminate and the water temperature will begin to increase on the display panel. If the disposable set is incorrectly installed and the unit is turned ON, the yellow "CHECK DISPOSABLE" light will illuminate and an intermittent alarm will sound. Priming Disposable Sets

! WARNING !

Set up, priming and use require aseptic technique. Follow applicable hospital policy and procedures.

! WARNING ! Remove all air from fluid bags before spiking with D-series disposable set.

! WARNING ! All air must be removed from fluid lines prior to patient connection. Failure to do so could result in the introduction of air to the patient.

! WARNING ! Monitor fluid lines to ensure they are air-free. Never infuse fluids if there are bubbles in the line between the filter chamber and patient connection. 1. CLOSE the Y-Set clamps. 2. Remove one bag spike cap and spike it into an air-free fluid bag with a twisting motion. 3. Hang the fluid bag from the adjustable I.V. pole and open the lead clamp to the I.V. bag. 4. Squeeze the drip chamber to the I.V. bag so it is 1/3 to 1/2 full. 5. Remove the male luer cap on the patient line and open the Y-set clamps to the I.V. bag. 6. Close the patient line clamp when the disposable set is completely primed. The filter with gas vent will self prime. 7. Gently tap the filter with gas vent against the cabinet to release all trapped air. Priming is complete. Make patient connection without entrapping air. 8. Adjust flow rate using roller clamp. Filter with Gas Vent Replacement in I.V. Disposable Sets Replace the filter with gas vent every THREE HOURS or when the filter becomes clogged or air is slowly vented. Replace with Level 1® product number F-10 or F-30. Refer to disposable packaging for appropriate filter replacement product number.

13

! WARNING ! Replacement filter with gas vent must be fully primed before continuing infusion. Thoroughly check patient line for air bubbles before opening roller clamp. If air bubbles are present, disconnect from the patient and re-prime before continuing infusion. 1. Close all clamps on the D-series disposable set and on new filter with gas vent. 2. Remove the used filter with gas vent from the holder while still connected to the disposable set. 3. Install the new filter assembly into the #3 holder. 4. Using aseptic technique, disconnect upper luer-lock fitting and, after removing upper male luer end cap from the new filter, connect the set to the new filter inlet. 5. Holding the used filter horizontally, disconnect the lower patient line luer-lock. Connect the used filter luer-lock fittings together and discard. 6. With the filter outlet tube clamped, open the clamps above the filter. The filter with gas vent will self prime. 7. Slowly release the outlet tube clamp and allow the outlet tube to fill completely. 8. Remove the second luer-lock end cap and connect the outlet tube luer-lock to patient line. 9. Remove the filter with gas vent from its holder and tap it against the cabinet several times until all trapped air bubbles have been vented out. Return the filter to its holder. Note: The "CHECK DISPOSABLE" alarm will be activated whenever the filter with gas vent assembly is removed from its #3 holder.

14

Trouble Shooting PROBLEM

THINGS TO CHECK

No Power

Make sure that the unit is plugged in and the power switch is ON. Is it plugged into correct circuit?

Check Disposables Alarm

Make sure the heat exchanger and filter are properly installed and the top (#2) socket is down. If the top (#2) socket is not properly seated, the yellow light next to it will illuminate.

Add Water Alarm

Make sure that the water tank is filled above the minimum mark level. Fill or top off the tank with DISTILLED water only.

Water Over Temperature Alarm

Turn off the power switch to clear the alarm. Turn on the power switch again. If the unit continues to alarm, remove it from service for repair.

Hot cabinet

Make sure that the air inlet on the bottom of the unit is not blocked or clogged with dust.

Difficult to Install Heat Exchanger

Lubricate the O-Rings in heat exchanger (#1) and (#2) sockets with silicone. Order Part # 80-04-002 to replace O-Rings.

15

Trouble Shooting Slow Flow Rates Many factors which are insignificant in low fluid administration are restrictors of higher flow infusion. If you encounter flow restriction with any Level 1® Fluid Warmer, CHECK EACH OF THESE POSSIBLE CAUSES. OLD BLOOD Stored blood begins to develop particulate within 5 to 7 days. This may partially block fluid pathways, impeding flow. FULLY SPIKED BAG Bag port membranes may only be split, not completely pierced. BAG PORT FILTER (if used) 40 micron to 80 micron filters used between the blood bag and the bag spike of the Disposable set may restrict flow because: 1. Cold, viscous blood does not flow well through small pore filters. 2. As they are directly connected to the source of particulate with no prefiltering, they clog quickly. 3. They may trap air which can block filter media surface area. CLAMPS PARTLY ENGAGED Check to be sure all clamps are fully open. TUBE SET Leaving clamps engaged for extended periods of time when the Disposable Set is not in use (such as pre-set-up) will cause the tubing to take a SET in the clamped position. TUBE KINK Be sure no tube kinks are present anywhere in the set, especially in the Y-set when a pressure cuff is employed and the IV Pole is used in a lowered position. TRAPPED AIR IN FILTER As noted in the Priming instructions, remove the Filter from the holder and tap against the Cabinet to dislodge air bubbles and allow them to vent out. CLOGGED FILTER If good quality blood is used, this filter should never cause flow restriction. In the event of a clogged filter, this component may be changed. If frequent clogging is encountered, discuss the QUALITY of the blood being used with your Blood Bank EXTENSION LINES Use only extension lines with a bore of .130" (3.3 mm) or larger, equipped with large bore fittings, such as Level 1® Part No’s. X-36 or Y-30. STOPCOCK OR Y ADAPTER Any fittings attached to the male luer-lock at the end of the Patient Line should have large bores. If their bores are smaller than the male luer-lock bore, they are restrictors. NEEDLE or CATHETER If possible, use a minimum 18 Gauge needle or 16 French catheter. Smaller sizes will reduce flow.

16

Testing The H-1000 is equipped with disposable set sensing interlocks. To operate the device and perform testing operations a Level 1® non-sterile, not for patient use D-series disposable set with heat exchanger and filter assembly must be in place.

! WARNING ! Do not attempt to defeat the disposable sensing interlocks or try to operate the H-1000 without a disposable in place. Water may spill from the unit if the interlocks are defeated. CAUTION: Prior to placing the H-1000 into service, the device must be tested by Smiths Medical technical personnel, an authorized distributor of Smiths Medical or a trained biomedical engineer. Periodic testing and maintenance should be performed by a biomedical engineer or trained personnel. NOTE: Refer to Maintenance and Testing Log section of this manual for safety testing frequencies and intervals. Add Water Alarm The H-1000 is equipped with a float switch which senses the water level in the onboard reservoir. When the water level is too low, a yellow indicator on the display panel illuminates and an audible alarm sounds. In the alarm condition the pump will not circulate water. With a test disposable set in place, the ADD WATER alarm may be tested by turning the drain valve on the bottom of the unit 90 degrees clockwise and allowing water to drain out into a container. Drain until the water level falls below the minimum mark on the water tank. Check Disposables Alarm Three interlocks sense a properly installed heat exchanger. If a heat exchanger is not in place and the power switch is ON, a yellow indicator will illuminate and an audible alarm will sound. With the unit running, the interlocks may be tested one at a time by following these simple steps. 1. Top Heat Exchanger Socket Slide up slowly, two yellow indicators will illuminate and the audible alarm will sound. 2. Heat exchanger interlock Gently pull on the middle of the heat exchanger, one yellow indicator will illuminate and the audible alarm will sound. 3. Filter holder interlock Remove the Filter with Gas Vent, one yellow indicator will illuminate and the audible alarm will sound.

17

Water Over Temperature Alarm Press and hold the Water Over Temperature alarm test button on the power and test panel on the front of the unit. The display will jump to 45 °C (as long as the button is pressed on), and the red over temperature indicator will illuminate and the audible alarm will start to pulse. NOTE: The Water Over Temperature Alarm test button actually tests the over temperature circuitry of the system, not just the visible red display indicator and the audible alarm. NOTE: Pressing the Water Over Temperature test button or the Alarm test button will disable the H-1000 even after the buttons have been released. The unit must be shut off and then re-started to clear the alarm condition. Alarm Testing The audible alarm and all indicator lights may be tested by pressing the Alarm test button on the power and test panel on the front of the cabinet. NOTE: Pressing the Alarm test button or the Water Over Temperature test button will disable the H-1000 even after the buttons have been released. The unit must be shut off and then re-started to clear the alarm condition. Performance Testing Periodic testing of the overall operating efficiency of the H-1000 can be accomplished in one of two simple ways: 1. COLD START TEST NOTE: This performance test requires a non-sterile, not for patient use Level 1® D-series disposable set to be installed properly on the H-1000. Store the H-1000 unit in a room where the room temperature is approximately 21 °C (70 °F). With a non-sterile D-series disposable set in place, note the time, and then turn the power switch ON. The green "OPERATING" indicator will illuminate. Rapidly rising numbers will appear on the circulating water bath temperature display. A 41 °C temperature reading will appear in approximately 3 to 7 minutes on an efficiently operating unit. NOTE: If the H-1000 does not pass the cold start test, it should be returned to Smiths Medical or an authorized distributor of Smiths Medical for service. Do not attempt to change the calibration settings. 2. THERMAL CALIBRATION WELL (TCW) Available from Smiths Medical, a TCW may also be used to test performance and confirm proper calibration of the water bath temperature.

18

NOTE: Use of the TCW requires a digital thermometer NIST traceable and accurate to within 0.1 °C. Required probe size: 0.099" OD maximum (0.25 cm) 0.50" - 1.50" long (1.27 - 3.81cm) A short procedure to verify the displayed circulating water bath temperature is as follows: 1. Install TCW in machine in normal heat exchanger position (Socket #s 1 & 2) and install a test filter assembly at holder (#3). 2. Turn the machine on and allow to warm up for 20 minutes. Insert thermometer probe fully into well and allow display to stabilize. Compare temperatures. 3. The H-1000 display will be within 0.3 °C of the thermometer display on a correctly calibrated unit. Examples: a. If the thermometer reads 41.4 °C and the H-1000 is within the range of 41.1 °C - 41.7 °C, performance is acceptable. b. If the thermometer reads 42.0 °C and the H-1000 is within the range of 41.7 °C - 42.3 °C, performance is acceptable. NOTE: If the system does not conform to within these specifications, it should be returned to Smiths Medical or an authorized distributor of Smiths Medical for service. 3. D-SERIES CALIBRATION THERMOMETER (”TempCheck”) Available from Smiths Medical, the TempCheck device may also be used to test performance and confirm proper calibration of the water bath temperature. The D-series TempCheck device accurately verifies the temperature of the H-1000 circulating water bath. It plugs into the auxiliary outlet on the bottom of the H-1000 and does not require a separate NIST traceable digital thermometer for operation. Earth leakage The H-1000 must be tested according to IEC 601-1 clause 19. Earth leakage current testing should be performed with the immersion heater circuit in the full ON condition. In order to be sure the heater circuit is in a full ON condition, testing should be performed on units which have been allowed to stand at room temperature, and have room temperature water in the water reservoir before the unit is turned ON. The H-1000 warms up quickly, test readings must be taken within 1 minute of startup. A steel stud is positioned on the back of the unit for earth leakage testing. Units not meeting this standard should be returned to Smiths Medical or an authorized distributor of Smiths Medical for service.

19