Smiths Medical

Graseby Syringe Drivers

Graseby MS16A and MS26 Syringe Driver Instruction Manual May 2008

Instruction Manual

44 Pages

Preview

Page 1

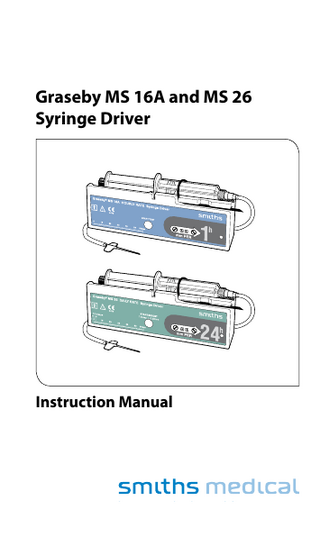

Graseby MS 16A and MS 26 Syringe Driver

Instruction Manual

Published by Smiths Medical MD, Inc. All possible care has been taken in the preparation of this publication, but Smiths Medical accepts no liability for any inaccuracies that may be found. Smiths Medical reserves the right to make changes without notice both to this publication and to the product which it describes. © 2008 Smiths Medical family of companies. All rights reserved. No part of this publication may be reproduced, transmitted, transcribed, or stored in a retrieval system or translated into any human or computer language in any form or by any means without the prior permission of Smiths Medical. Smiths Medical MD, Inc. 1265 Grey Fox Road, St. Paul, MN 55112, U.S.A. European Representative: Smiths Medical International Limited Watford, Hertfordshire, UK, WD24 4LG Registered in England. Company number 362847

Trademarks and acknowledgements: Graseby and the Smiths design mark are a trademarks of the Smiths Medical family of companies. The symbol ® indicates the trademark is registered in the U.S. Patent and Trademark office and certain other countries. All other names and marks mentioned are the trade names, trademarks or service marks of their respective owners.

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual

Contents Warnings/ Caution... 3 1 Instructions for the Graseby.

MS 16A and for MS the 26 Syringe Instructions GrasebyDrivers... 7 Product Literature... 7 Pack contents... 7 Introduction... 7 What is a Syringe Driver?... 8 What are the differences between a Graseby MS 16A and MS 26 Driver?... 8 Why are there two models?... 9 How to use the Syringe Driver... 9 Do’s and Don’ts... 9 .Fitting the battery...10 What the controls do...11 What the symbols on the Syringe Driver mean...12 Selecting a syringe ...13 Identifying the model, Graseby MS 16A or MS 26 Syringe Driver...13 Setting the correct rate for the Graseby MS 16A...14 Setting the correct rate for the Graseby MS 26...16 Notes on setting up your Syringe Driver...18 Fitting the syringe...18 Fitting the cover...19 Using the lockbox...20 Starting the Syringe Driver...21 During the administration...22 How to use the Boost Dose on the Graseby MS 26...22 Stopping the Syringe Driver...23 Alarms...23 Accessories...24 Care and Maintenance...25 Battery replacement... 25 Cleaning... 26 Storage... 26 Servicing... 26 Disposal... 26 Troubleshooting... 28

2

Guide to subcutaneous analgesia...29 Parenteral administration of drugs...29 Indications...29 Converting from oral to parenteral administration...29 Drugs commonly administered using syringe drivers...29 .What is needed for a subcutaneous infusion with the .Syringe Driver?...30 .Selection of a suitable infusion site... 31 .Inserting the Subcutaneous Needle... 31 .Observation during treatment... 31

3

Technical and Performance Specification...32 Standards...38

1

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual

2

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual

Warnings/ Cautions Warnings Warnings tell you about dangerous conditions that could lead to death or serious injury to the user or patient, which can occur if you do not obey all the instructions in this manual. 1. WARNING: Always ensure that the correct driver is being used for the infusion. The Graseby MS 16A Syringe Driver is for hourly rate infusions between 30 minutes and 24 hours and has a blue label. The Graseby MS 26 Syringe Driver is for daily rate infusions of 1 day or longer and has a green label. Failure to use the correct model driver may result in an inaccurate delivery of medication, resulting in patient injury or death. 2. WARNING: To avoid incorrect or inappropriate infusion volumes, the correct rate may only be set by qualified persons or authorised personnel. Incorrect rate settings could lead to an inappropriate infusion resulting in patient injury or death. 3. WARNING: In order to ensure that the intended infusion is performed, the rate must be entered correctly. Failure to do so may result in compromised function of the product, patient injury or death. 4. WARNING: This equipment is not suitable for use in the presence of flammable anaesthetic mixtures with air, oxygen, or nitrous oxide. The use of the device in presence of such mixtures may lead to explosion or fire. 5. WARNING: To avoid possible malfunction of the driver, do not expose the driver to X- rays, gamma rays or ionizing radiation, or to the RF interference or strong electric/ magnetic fields emitted (for example) by diathermy equipment or mobile telephones. If the driver is used in the presence of, or in combination with Magnetic Resonance Imaging (MRI) machines it must be protected from the magnetic field emitted by such equipment. Malfunction of the pump can cause incorrect infusion or loss of infusion resulting in patient injury or death. 6. WARNING: Operation of the driver outside the temperature limits defined in the Specification may result in erroneous operation. Ensure that the temperature is within the specified limits. Failure to do so may result in patient injury or death. 7. WARNING: The driver may only be opened by a suitably qualified engineer. Unauthorised modifications may result in the compromised functioning of the driver, leading to patient or user injury or death. 8. WARNING: Failure to follow the Maintenance and Test Procedures described the Graseby MS 16A and MS 26 Syringe Driver Technical Service Manual may result in compromised function of the product and lead to patient injury or death. 9. WARNING: It is essential that the visual and audible alarms on the driver are not obscured so that all alarms are responded to promptly. Failure to respond promptly to an alarm may result in patient injury or death. 10. WARNING: The user should ensure that the performance offered by the driver is fit for the intended purpose. Failure to do so may result in compromised function of the product, patient injury or death. 11. WARNING: Do not use a faulty driver. If the driver detects a fault, a 15 second alarm will sound. If this happens, the driver must not be used until a suitably qualified engineer has tested and rectified the fault. Incorrect performance of the driver can cause complications resulting in patient injury or death. 11. WARNING: Ensure that the correct battery type is fitted, correctly installed and with adequate charge for the infusion. Failure to do so may lead to impaired functioning of the driver, resulting in patient injury or death.

3

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual 12. WARNING: Use only a syringe within the range specified in the Technical and Performance Specifications at the end of this manual. Failure to do so may result in an inaccurate delivery. Smiths Medical does not guarantee performance of the driver if syringes other than those listed are used. Incorrect function or performance of the driver can cause complications resulting in patient injury or death. 13. WARNING: Do not move the driver between extremes of humidity. Condensation may form inside the driver, resulting in the incorrect function or performance of the driver which may cause complications resulting in patient injury or death. 14. WARNING: The volume of fluid contained in the connecting tubing is a residual amount and will not be infused. Allowance must be made for this extra volume of fluid when initially filling the syringe and purging the system. Under-delivery of medication can cause complications resulting in patient injury or death. 15. WARNING: To avoid patient embolism, ensure that the patient tubing is purged of all air bubbles before administering any medication. The presence of air within the medication can result in complications leading to patient injury or death. 16. WARNING: For safe operation of the driver, the syringe must be correctly loaded. Ensure that the syringe plunger is properly aligned before tightening the securing strap. Failure to do so may result in inaccurate delivery, resulting in patient injury or death. 17. WARNING: To avoid syphoning of the syringe contents (free flow), ensure that the syringe is correctly loaded into the driver, that the syringe plunger is properly engaged by the driver’s actuator and that the driver is placed not more than 80 cm above the infusion site. Syphoning can result in over-infusion leading to patient injury or death. 18. WARNING: To avoid over-infusion, do not purge the infusion line when the administration set is connected to the patient. Over-infusion of medication can result in patient injury or death. 19. WARNING: Only use the driver if the rubber securing strap is correctly positioned over the syringe and firmly hooked in place. An incorrectly secured driver may cause an uncontrolled delivery of infusate to the patient, resulting in patient injury or death. 20. WARNING: When not used as an ambulatory driver, ensure that the driver is stable and secure and that the syringe is on the top of the driver and horizontal. The Non-slip Base should be used and placed on an horizontal surface. Failure to observe this warning may cause damage to the driver and harm the patient. As a result, the patient may suffer direct injury, or the driver may fail to operate correctly, leading to patient injury or death. 21. WARNING: When used in an ambulatory mode, the driver must be secured within the holster with the clear, rigid plastic cover fitted. Failure to do so may result in compromised functioning of the pump, leading to patient or user injury or death. 22. WARNING: To prevent the driver being tampered with, the driver must be locked in the Graseby Lockbox. The key must be held by an authorised person. Failure to do so may result in misuse of the pump, leading to patient or user injury or death. 23. WARNING: Following a significant liquid spill onto the driver or the Lockbox, it should be withdrawn from use, wiped dry and inspected and tested by service personnel before being returned to service. Failure to do so may result in compromised functioning of the driver, leading to patient or user injury or death. 24. WARNING: To avoid syphoning of the syringe contents (free flow), ensure that the patient line is clamped before loading or unloading the syringe. Syphoning can result in over-infusion leading to patient injury or death.

4

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual 25. WARNING: When the driver is used in a Lockbox, the alarm volume may be moderately reduced. Failing to hear and respond to the alarm may result in patient injury or death. 26. WARNING: When the driver is used in a Lockbox, ensure that tubing is not trapped or kinked. Misdelivery of medication can cause complications resulting in patient injury or death.

Cautions Cautions tell you about dangerous conditions that may occur and cause damage to the driver if you do not obey all of the instructions in this manual. 1. CAUTION: Do not use cleaning and disinfecting agents other than the approved ones specified here. Agents not approved may damage the driver. 2. CAUTION: Do not immerse either the driver or the Lockbox in any liquids or expose them to strong organic solvents. Wipe off spills immediately, and do not allow fluid or residues to remain. Additionally, the driver and Lockbox are not designed to be autoclaved, steam-sterilised, EtO-sterilised or subjected to temperatures in excess of 45° C (113° F). Failure to observe this caution may cause serious damage to the driver. 3. CAUTION: Always use the correct type and size of battery. The driver may be damaged if an attempt is made to fit an incorrect size battery.

5

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual

Dimensions: 166 x 53 x 23 mm without syringe or cover

The Graseby MS 16A HOURLY RATE Syringe Driver

Dimensions: 166 x 53 x 23 mm without syringe or cover

The Graseby MS 26 DAILY RATE Syringe Driver

6

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual

1 Instructions for the Graseby MS 16A and MS 26 Syringe Drivers WARNING: These instructions contain important information for safe use of the product. Read the entire contents of these Instructions For Use, including Warnings and Cautions, before using the Graseby MS 16A and MS 26 Syringe Drivers. Failure to properly follow warnings, cautions and instructions could result in death or serious injury to the patient.

Product Literature The Instruction manual, part number 0105-0549 is supplied with the Graseby MS 16A and MS 26 Syringe Drivers. Other product literature includes: •

MS 16A Technical service manual - part number OOSM-0106

•

MS 26 Technical service manual - part number 00SM-0113

The Instruction manual is also available in the following languages: •

French, German, Greek, Italian, Spanish and Swedish

Pack contents MS 16A Syringe Driver - packed set, part number 0105-0504 MS 26 Syringe Driver - packed set, part number 0113-0001 Each pack contains the following items: •

Syringe Driver

•

Syringe cover (clear plastic)

•

Syringe holster (fabric)

•

Rate adjuster

•

Instruction manual

•

Battery, type MN1604

Introduction This manual contains instructions on how to use and care for the Syringe Driver safely, and what to do if it should go wrong. Please take time to read all the information before you start to use the Syringe Driver; follow all warnings printed in bold type. The Syringe Driver is a medical device designed and made to achieve a high level of safety protection. Before using the Syringe Driver, refer to the performance specification to ensure suitability for the treatment. Incorrect use could result in patient injury of death. The Syringe Driver must only be used under the supervision of a medical professional. Please ensure that a copy of this Instruction Manual is given to the person responsible for using the Syringe Driver. WARNING: To avoid incorrect or inappropriate infusion volumes, the rate may only be set by qualified persons or authorised personnel. Incorrect rate settings could lead to an inappropriate infusion resulting in patient injury or death.

7

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual

What is a Syringe Driver? A Syringe Driver is a power driven device for pushing the plunger of a syringe forward at an accurately controlled rate. It is an aid in administering medicinal preparations in liquid form over much longer periods than could be achieved by injecting by hand. A suitable sterile syringe with a sterile pathway is also required to deliver medication to the patient. The Graseby MS 16A and MS 26 Syringe Drivers are both non-sterile devices. They are battery powered ambulatory devices, that can be carried by patients whilst undergoing treatment. The Syringe Drivers are suitable for administering medication intravenously (IV) or subcutaneously. For more information on subcutaneous infusion therapy, see the section Guide to subcutaneous analgesia. A driver may be reused if it is in good condition and has been regularly tested and maintained.

What are the differences between the Graseby MS 16A and MS 26 Syringe Drivers? It is most important to be familiar with what the differences are. The most visible difference is the colour; the MS 16A has a blue label and the MS 26 a green one. The table shows all the main differences: Feature Rate range Indicator lamp flashes every Motor turns every Test time

MS 16A HOURLY RATE

MS 26 DAILY RATE

0 - 99 mm per hour

0 - 99 mm per 24 hours

1 second

25 seconds

(420 ÷ rate set) minutes

(168 ÷ rate set) minutes

5 seconds

10 seconds

Boost

NO

YES

Label colour

Blue

Green

WARNING: Always ensure that the correct driver is being used for the infusion. The Graseby MS 16A Syringe Driver is for hourly rate infusions between 30 minutes and 24 hours and has a blue label. The Graseby MS 26 Syringe Driver is for daily rate infusions of 1 day or longer and has a green label. Failure to use the correct model driver may result in an inaccurate delivery of medication, resulting in patient injury or death.

8

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual

Why are there two models? The MS 16A is intended for administrations lasting between 30 minutes and 24 hours. The rate setting is in millimetres (mm) of syringe plunger movement every hour. The MS 16A is known as the HOURLY RATE Syringe Driver. For slower infusions, the MS 26 is intended for administrations over periods of 1 day and longer. The rate setting is in millimetres (mm) of syringe plunger movement every 24 hours. The MS 26 is known as the DAILY RATE Syringe Driver. At the slowest setting, of 01, the MS 26 would take 60 days to move the actuator over the full length of travel. The MS 26 can also be used to give manually administered boost doses during the administration.

How to use the Syringe Driver Do’s and Don’ts DO

check the battery daily.

DO

avoid using mobile telephones close, nearer than 1 metre, to the Syringe Driver. Although there have been no confirmed reports of mobile telephones interfering with the operation of the Syringe Driver, following this advice will help reduce any risk.

DON’T

use the Syringe Driver without understanding these instructions.

DON’T

get it wet. It is not waterproof, even when enclosed in a Lockbox, and the performance will be affected.

DON’T

take it from a cool environment and put it into a warm, very humid environment (e.g. an incubator) or take it from there into a cooler one. Condensation will form and the inside will get wet.

DON’T

use the Syringe Driver without understanding these instructions.

DON’T

take it from a cool environment and put it into a warm, very humid environment (e.g. an incubator) or take it from there into a cooler one. Condensation will form and the inside will get wet.

DON’T

open it up to look inside. The performance will be affected.

DON’T

use it in or near strong magnetic fields, Nuclear Magnetic Resonance (NMR) scanners for example. They may stop it.

DON’T

use it in the presence of flammable anaesthetic gases or in an oxygen enriched atmosphere. It may increase the risk of a fire or explosion.

DON’T

use it outside its temperature range. The performance will be affected.

DON’T

wipe it with organic cleaning solvents or strong disinfectants. The plastic case may be damaged.

9

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual

Fitting the battery Always fit a 9 volt (9 V) ‘alkaline’ battery. Alkaline batteries can be identified by the international code 6LR61 marked on them or on their packaging. They are available from most retail outlets selling batteries. A recommended battery of this type is the DURACELL MN1604. Be careful when selecting a battery as some brands may not fit properly. If possible, try the battery in the battery compartment first. Never try to force in a battery which is too large as this may damage the battery contacts. Batteries of the ‘zinc-carbon’ type (marked 6F22 or 6R61), for example a PP3, are not recommended. They perform poorly with the Syringe Driver and need to be replaced more often. To fit a battery: Slide off the cover at the back of the Syringe Driver.

2.

Push in the battery. The label in the battery compartment shows which way round to put it. Accidentally putting it in the wrong way round will not do any harm.

3.

Slide the cover on again until it latches shut.

_

+

1.

GM0305-A

The alarm will sound for about 15 seconds after the battery is fitted. To remove a battery, see page 25.

CAUTION: Always use the correct type and size of battery. The driver may be damaged if an attempt is made to fit an incorrect size battery.

10

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual

What the controls do Rate setting switches These are the two switches that set the rate (speed) at which the syringe plunger will be pushed forwards. This is the distance, in mm, that the plunger will move in one hour on an MS 16A and in one day on an MS 26.

0 9 mm PER GM0307-A

There is one switch for the ‘tens’ and one for the ‘units’ of the rate value. Values from 0 to 99 can be set. The numbers set appear in the windows next to each switch. The switches can be turned with the key supplied or with a small screwdriver with a flat blade. WARNING: The correct rate may only be set by qualified persons or authorised personnel. Incorrect rate settings could lead to an inappropriate infusion resulting in patient injury or death. WARNING: In order to ensure that the intended infusion is performed, the rate must be entered correctly. Failure to do so may result in compromised function of the product, patient injury or death.

START/TEST button (MS 16A) Pressing and holding this button down tests the safety system. Releasing it starts the MS 16A.

START/BOOST button (MS 26) Pressing and holding this button down tests the safety system and allows a boost dose to be administered by counting the sound beeps. Releasing it starts the MS 26.

Actuator release button Pressing and holding this button down releases the actuator so it can be moved backwards or forwards by hand. GM0310-A

11

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual

What the symbols on the Syringe Driver mean An electrical safety classification in the international safety standard for medical electrical equipment, Type BF. If the equipment is used as intended there is no risk of a serious electric shock. But it is not suitable for direct connection to the heart. Refer to the accompanying instructions on how to use the equipment. The instructions are all in this manual.

Refer to page 34. Refer to page 34.

Refer to page 34.

12

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual

Selecting a syringe Most of the small sterile plastic syringes available, from 2 ml up to 35 ml capacity, can be used. Syringes with a Luer lock nozzle are best because they offer more security against accidental disconnection of the infusion line. Choose a syringe brand and size that fits properly onto the Syringe Driver. The adjustable strap must fit round it to hold it firmly, the finger grip and the plunger push-button must fit in the retaining slots in the case and actuator.

GM0419-A

GM0467-A

With some of the larger sizes it may not be possible to fill them to their full capacity but they can still be used as long as they fit on properly.

Identifying the model - Graseby MS 16A or MS 26 Syringe Driver The MS 16A is the HOURLY RATE model with the rate in mm per 1 h and has a BLUE label The MS 26 is the DAILY RATE model with the rate in mm per 24 h and has a GREEN label. WARNING: For safe operation of the driver, the syringe must be correctly loaded. Ensure that the syringe plunger is properly aligned before tightening the securing strap. Failure to do so may result in inaccurate delivery, resulting in patient injury or death. WARNING: Always ensure that the correct driver is being used for the infusion. The Graseby MS 16A Syringe Driver is for hourly rate infusions between 30 minutes and 24 hours and has a blue label. The Graseby MS 26 Syringe Driver is for daily rate infusions of 1 day or longer and has a green label. Failure to use the correct model driver may result in an inaccurate delivery of medication, resulting in patient injury or death. 13

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual

Setting the correct rate for the Graseby MS 16A 1.

Fill the syringe with the required volume of medication.

2.

Connect and fill the infusion line. Make sure the connection is secure and the air is expelled.

3.

Measure the distance, in millimetres (mm), from the empty (0) line on the syringe’s scale up to the line where the plunger piston is. There is a ‘mm’ scale on the front of the MS 16A for this.

4.

Divide this distance, measured in mm, by the time in hours (h) all the medication in the syringe needs to be administered in. The answer is the rate to set in the rate windows

mm

GM0313-A

Distance in mm ÷ Time in hours = Rate in mm per 1 h

0

14

10

20

30

40

50

60

mm

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual

Here is an example: A syringe is to be used to administer 8 ml of medication over 12 hours. With this syringe filled to the 8 ml line, the plunger travel measures 48 mm.

48 mm ÷ 12 hours = 4 mm per 1 h

Set the rate switches to 04

Each switch must be moved until all of the number can be seen in the window. In this example, every hour the syringe plunger will move forwards 4 mm, administering about 0.67 ml of the medication and after 12 hours the syringe will have emptied. Remember that for rates up to 9 the left-hand ‘tens’ number must be set at 0. If the result of the division is not a whole number select the nearest whole number for the rate. REMEMBER THAT YOU HAVE TO SET THE RATE IN MILLIMETRES (mm) NOT MILLILITRES (ml).

15

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual

Setting the correct rate for the Graseby MS 26 1.

Fill the syringe with the required volume of medication.

2.

Connect and fill the infusion line. Make sure the connection is secure and the air is expelled.

3.

Measure the distance, in millimetres (mm), from the empty (0) line on the syringe’s scale up to the line where the plunger piston is. There is a ‘mm’ scale on the front of the MS 26 for this.

mm

GM0313-A

4.

Divide this distance, measured in mm, by the time in days (24 hour (h) periods) all the medication in the syringe needs to be administered in. The answer is the rate to set in the rate windows.

Distance in mm ÷ Time in days = Rate in mm per 24 h

0

16

10

20

30

40

50

60

mm

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual Here is an example: A syringe is to be used to administer 8 ml of medication over 2 days. With this syringe filled to the 8 ml line, the plunger travel measures 48 mm.

48 mm ÷ 2 days = 24 mm per 24 h

Set the rate switches to 24

Each switch must be moved until all of the number can be seen in the window. In this example, every 24 hours the syringe plunger will move forwards 24 mm, administering about 4 ml of the medication and after 48 hours the syringe will have emptied. Remember that for rates up to 9 the left-hand ‘tens’ number must be set at 0. If the result of the division is not a whole number, select the nearest whole number for the rate. REMEMBER THAT YOU HAVE TO SET THE RATE IN MILLIMETRES (mm) NOT MILLILITRES (ml).

17

Graseby MS 16A and MS 26 Syringe Drivers Instruction Manual

Notes on setting up your Syringe Driver An alternative method may be used to set up the Graseby MS 16A or MS 26 Syringe Driver if a specific policy has been devised as part of your hospital/ community protocol. The alternative method involves first measuring the volume in the syringe, then priming the line. Precaution: If you measure first, then prime the line, the infusion will finish early. You should therefore only use this method when your hospital has devised this protocol for a specific clinical area.

Fitting the syringe 1.

Put the syringe on top of the Syringe Driver, with its barrel in the shallow V-shaped recess. The finger grip on the syringe barrel must be in the slot in the case.

2.

Move the actuator up to the syringe plunger, by pressing and holding in the button on the side, and sliding it along. The push-button on the plunger of the syringe must be fitted in the slot in the actuator. Be careful not to push the plungers.

3.

GM0309-A

Older versions did not have the slot in the actuator for the syringe plunger push-button. A small metal screw-clamp was supplied and this must be fitted through the hole in the actuator and used to hold the plunger push-button. The actuator can be replaced by the latest type and it is recommended that this is done the next time the Syringe Driver is overhauled. 4.

Put the rubber securing strap over the syringe barrel and pull it tight. Hook and then press it into the groove in the side of the case.

Precaution: Risk of uncontrolled flow into the patient. Only use the Driver if the syringe can be secured as described. If the selected syringe does not fit, try another brand of syringe with the same capacity. Precaution: The rate setting used may need to be changed so the dose is administered in the same time. Recalculate the correct rate to use.

18