Spectrum Medical

System M User Manual Product Codes M2, M3 and M4 Ver 3 Aug 2015

User Manual

33 Pages

Preview

Page 1

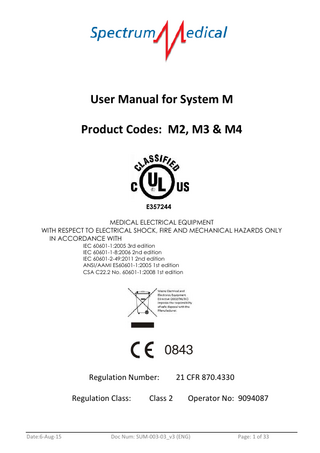

User Manual for System M Product Codes: M2, M3 & M4

E357244 MEDICAL ELECTRICAL EQUIPMENT WITH RESPECT TO ELECTRICAL SHOCK, FIRE AND MECHANICAL HAZARDS ONLY IN ACCORDANCE WITH IEC 60601-1:2005 3rd edition IEC 60601-1-8:2006 2nd edition IEC 60601-2-49:2011 2nd edition ANSI/AAMI ES60601-1:2005 1st edition CSA C22.2 No. 60601-1:2008 1st edition

0843 Regulation Number: Regulation Class:

Date:6-Aug-15

Class 2

21 CFR 870.4330 Operator No: 9094087

Doc Num: SUM-003-03_v3 (ENG)

Page: 1 of 33

Table of Contents User Manual For System M ... 1 Introduction ... 4 Intended Use ... 4 The Measurement of SaO2 and SvO2 ... 5 The measurement of Hemoglobin and calculated Hematocrit: ... 5 The measurement of blood flow rate and emboli ... 5 Gas module measurements ... 5 Safety Instructions ... 6 Safety Symbols ... 7 Monitor Overview ... 8 Assembling the Monitoring System ... 9 Main User Controls ... 13 Power On / Power Off: ... 13 Main Screen Layout (M4 shown for illustration purposes) ... 13 Start, Pause & Stop Functions ... 14 Graph Controls ... 14 Details Screen ... 14 Setup sub screen ... 15 Medical Physics page ... 15 Machine Configuration page ... 15 Gauge Configuration... 16 Graph Configuration ... 17 Parameter Configuration ... 17 Gas and Fluid Flow Configuration ... 18 PO2 and PCO2 ... 18 Emboli Setup... 19 O2 and CO2 sensor calibration ... 19 Status Bar ... 19 Backup battery ... 20 Alarm System ... 21 Technical alarms: ... 22 Electromagnetic Compatibility (EMC) ... 23 Guidance and manufacturer’s declaration – electromagnetic emission ... 23 Guidance and manufacturer’s declaration – electromagnetic immunity... 23 Recommended separation distances between portable and mobile RF Communications equipment and the Spectrum Medical monitoring system ... 25 Service Manual For System M ... 26 Trouble shooting ... 27 Common SO2 problems and advice ... 27 Common Hb / Hct problems and advice ... 27 Common Flow and Emboli problems and advice ... 27 Trouble Shooting the Gas Module ... 28 Servicing ... 29 System Diagnostics / Software Release Status ... 29 General Servicing ... 29

Date:6-Aug-15

Doc Num: SUM-003-03_v3 (ENG)

Page: 2 of 33

Cleaning Spectrum Products ... 29 Routine Inspection... 29 Gas Module O2 sensor replacement ... 30 Gas Module Calibration ... 31 Software Upgrade Procedure ... 32 Additional Technical and Product Information ... 32 Transport, Storage & Disposal ... 32 Monitor Specifications... 32 Performance Specifications ... 33 Sensor Specifications ... 33 Regulatory Notices ... 33 Manufacturer’s Contact Address: ... 33

Date:6-Aug-15

Doc Num: SUM-003-03_v3 (ENG)

Page: 3 of 33

Introduction The System M Monitoring System from Spectrum Medical can be configured to measure a wide range of critical parameters both non-invasively and in real-time with in an extracorporeal circuit.

Intended Use M2

The M2 is configured to measure arterial and venous saturation, hemoglobin and a calculated hematocrit.

M3

The M3 is configured to measure arterial and venous saturation, hemoglobin and a calculated hematocrit concentration, multiple blood flows and gaseous emboli.

M4

The M4 is configured to measure arterial and venous saturation, hemoglobin, calculated hematocrit concentration and multiple blood flows, gaseous emboli, predicted PO2, predicted PCO2, FeCO2, FiCO2, FiO2, gas flow and Temperature.

VIPER DM

The Viper DM is a platform for running Viper Independent Data Management software which has no measurement capability.

The device provides monitoring information to trained clinicians and can be configured by them to set parameter specific alarms. The device has a monitoring and alarm function only; it does not directly control patient treatment nor sustain life. The user may make clinical judgements regarding the treatment of the patient as a result of information displayed by the device. Caution 1: Federal (US) law restricts this device to sale by or on the order of a physician. Caution 2: Failure to follow the instructions for use can cause the monitoring system to display inaccurate values. The accuracy of the results is dependent upon the following:

Reading and understanding the instructions for use Proper set-up of the device Use of all available system features Periodic comparison and synchronisation to a laboratory reference sample The gas module can use a supplied blood temperature and / or blood flow rate, the user needs to supply an ‘actual’ temperature for accuracy of results.

When a displayed value is significantly different from expectations, verification of results with laboratory analysis is recommended prior to initiating treatment.

Date:6-Aug-15

Doc Num: SUM-003-03_v3 (ENG)

Page: 4 of 33

Important Note:

Principles of Measurements

The Measurement of SaO2 and SvO2 The measurement of O2 saturation is achieved by analysing a specific region of the oxy-haemoglobin curve using 100 discrete wavelengths of light. The use of this non-invasive optical recognition technology ensures that the O2 Saturation measurement is highly accurate and extremely repeatable. A single synchronization with a reference blood gas system is all that is required. The measurement is independent of blood flow, blood temperature and blood dilution.

The measurement of Hemoglobin and calculated Hematocrit: Infrared light from an LED passes through a flowing tube of blood. A photodiode detects a receiving light level and converts the resultant light energy into a proportional electrical output. The sensors are pre-calibrated using a traceable reference. A software algorithm linearizes this relationship and converts the incoming signal to an actual reading of Hemoglobin and a calculated Hematocrit. Warning:

Only synchronize the M2 technology with a calibrated Blood Gas Analyser.

Do not synchronize with third party inline monitors as this will lead to inconsistent accuracy.

The measurement of blood flow rate and emboli Ultrasonic emitters and receivers are placed such that the energy is passed through the tube of blood. By monitoring the transmitted and received signals, the software is capable of determining flow rate and direction using phase variations. The sensing hardware is calibrated to a master flow meter using a traditional two point calibration for accurate results. Emboli are detected using the same sensing hardware but uses signal strength to determine the volume of emboli passing between the sensor emitters and receivers. The hardware is capable of very high speed sampling to ensure accuracy. The speed of the fluid flow and sensor size is taken into account when estimating emboli volume.

Gas module measurements FiO2 is measured using a galvanic cell to generate voltage from oxygen. CO2 is measured using an optical sensor. Gas flow rate is measured by detecting pressure drop across a fixed orifice using a delta P strain gauge transducer. Gas pressure is measured using an atmospheric pressure sensor that uses strain gauge technology. Blood temperature is measured using a thermistor sensor. PO2 and PCO2 are predicted results based upon a software algorithm that makes use of Blood Temperature, Blood flow rate, FiO2, FeCO2, FiCO2 and Gas Pressure. Both 37ºC and/or body temperature results can be displayed. Warning:

Date:6-Aug-15

Significant changes in blood temperature (greater than 12oC) may affect the accuracy of PO2 and PCO2 and therefore synchronisation with a laboratory reference sample may be required.

Doc Num: SUM-003-03_v3 (ENG)

Page: 5 of 33

Safety Instructions Not to be used internally or in a sterile environment. The use of the monitor is restricted to one patient at a time. The equipment is designed to be used only when continuously attended by a clinical operator. Information from still or slow flowing blood may not be valid. The fibre optic sensor cable must at all times be handled with care. Do not exceed the minimum bend radius of 50 mm. Do not touch any part of the monitor and the patient simultaneously. Do not connect the monitor to any equipment other than that approved by, or supplied by Spectrum Medical. Sensors should only be connected to blood pipes that are clean and free of dust and/or manufacturers’ markings. To avoid the risk of eye injury, do not stare directly into the sensor LEDs. It is recommended that an anti-bacterial filter is placed between the Gas Measurement Module and the Oxygenator. The monitor requires no special precautions to be taken to protect the patient or operator during defibrillation and the normal operation will resume at most 15 seconds after defibrillation.

Do not use the monitor in close proximity to magnetic fields (e.g. MRI scanners), sources of ionizing radiation or near wet environments such as baths or sinks. Do not cover the fan or ventilation holes when the monitor is in use or insert foreign objects into the memory card socket. Before connecting the monitor to a power source, ensure the voltage rating of the power supply matches that of the available power source. To avoid the risk of electric shock, the monitor must only be connected to a supply mains with a protective earth (ground). Use only the Spectrum Medical supplied IEC 60320 mains cable. Make sure the cable is located where it cannot be tripped over and nothing rests on it. Only use the IEC60601-1 approved power supply supplied with the monitor (Part No: PMP90-11-K17). Ensure sensors are connected to the blood pipes when monitoring and avoid using in strong ambient light. Do not use with silicone tubing. The monitor will emit low levels of electromagnetic radiation when Wifi communications are in use. The product is supplied with an Ethernet isolation device, this must be connected to the Ethernet port before connecting a network cable to the product. This device protects the equipment from faults on third party equipment.

Ensure that the monitor is positioned where it cannot be touched by the patient. Do not touch the monitor and the patient simultaneously. No special precautions need to be taken when using High Frequency surgical equipment. All sensors are isolated however we recommend all sensors and connections should be positioned to avoid contact with the patient and operator.

Date:6-Aug-15

Doc Num: SUM-003-03_v3 (ENG)

Page: 6 of 33

Safety Symbols Input / Output Network Connector

Caution, Consult Accompanying Documents before Use

The Fan inlet and outlet apertures should not be covered, to avoid overheating.

Suitable for Direct Current only.

Warning – Risk of Electric Shock

Ethernet Connection

Handle With Care

Non-ionising radiation

Defibrillation proof type BF applied part

Manufacturer Year

Date of manufacture

Waste Electrical and Electronic Equipment directive 2002/96/EC

Date:6-Aug-15

Doc Num: SUM-003-03_v3 (ENG)

Page: 7 of 33

Monitor Overview

Touch Screen

Sensor Connector (SO2 / HCT)

Power Button

Extended battery life with battery extension module

Wifi Aerial

User Serial port

Flow connectors

USB ports

DC power inlet

Ethernet port

Any mains-powered equipment which is connected to the USB or user serial ports must be approved to IEC 60601. Connecting any non-approved mains-powered equipment to these ports may cause a risk of electric shock to the patient or the operator.

Date:6-Aug-15

Doc Num: SUM-003-03_v3 (ENG)

Page: 8 of 33

Assembling the Monitoring System 1. Mount G Clamp

2. Attach Monitor to Support Arm

Quick release pins

Align the Monitor mounting system with the quick release system and latch together. To remove the Monitor from the mounting arm press together the two quick release pins and pull apart.

Attach the G Clamp to a rigid vertical pole and apply a medium force to the handle.

Warning

The support arm may pinch.

Only attach the Monitor to the support arm.

3. Connecting the Sensor Assemblies

To attach the SO2/HCT sensor to the monitor, first lift the sensor socket cover and insert the sensor connector with the red and black dots aligned; push until the sensor registers a light click.

To attach the flow sensors to the monitor, first select the required channel (1, 2 or 3), then insert the sensor connector with the red dots facing rearward; push until the sensor registers a light click.

6 pin connector

4 pin connector

To attach the gas module to the monitor, connect the USB lead into the monitor in USB II, then connect the other end to the gas module: (4 pin connector). Finally connect the exhaust CO2 sensor to the gas module: (6 pin connector). Correctly align the red dot on the plug lines up with the red rot on the socket.

Warning

Only attach the Spectrum Medical supplied accessories and cables. Do not force the cable connections, all cable connections are uniquely keyed for correct installation.

Date:6-Aug-15

Doc Num: SUM-003-03_v3 (ENG)

Page: 9 of 33

When using the gas module always provide an actual arterial temperature by using the jack connection on the CO2 exhaust sensor. The temperature sensor is to be inserted into the temperature port of the oxygenator so it reads Arterial Blood flow temperature.

4. Connection of Mains Power To connect mains power, plug the connector into the monitor aligning the red dots on the plug and socket. Then attach the power cord to the external power supply, then plug the power cord into the mains socket at your facility. To isolate the monitor system from the supply mains, unplug the power cord from the external power supply.

5. Memory Card Assembly (Insertion and Specification)

Insert the memory card as shown and apply light pressure until card is inserted. To remove card apply light pressure and the card will spring eject. The recording of data will commence from the time of insertion. The SD card is not required for the monitor to function. Use SD Cards supplied by Spectrum Medical only.

Date:6-Aug-15

Doc Num: SUM-003-03_v3 (ENG)

Page: 10 of 33

6. Making Sensor Connections to the PVC Extracorporeal Circuit. 6.1 Venous SO2 Sensor Note: For sensor and clip sizes see “Sensor Specifications” on page 32

Insert the sensor between the retention hooks until the sensor is secure. Ensure that both the blood tube and sensor assembly are free from dust and any form of contamination. To remove the sensor hold the blood pipe as shown and squeeze the retention hooks until sensor is released.

Attach the required size of pipe clip to the blood pipe. Ensure the retention clips are fully engaged

Warning:

Do not try to pull the sensor free with the fibre optic or coloured strain relief. To avoid causing damage always hold the sensor by the black coloured housing.

6.2 Arterial SO2 / Hct Sensor Ensure that both the blood tube and sensor assembly are free from dust and any form of contamination. Open lid and slide the blood tube into the sensor.

Warning:

Do not use any lubricants on the HCT/S02 sensor except Isopropyl Alcohol wipes to clean. Ensure the magnetic lid of sensor does not interfere with devices in close proximity. Flow and hematocrit sensor calibration is determined by tubing dimensions. Use on tubing other than specified generally yields inaccurate measurements and may cause erratic zero baseline drift.

6.3 Flow Sensor (M3 and M4 Monitors only) Ensure the sensor is free of dirt and contamination. Ensure the sensor is positioned with the arrow in the direction of flow.

Warning:

Date:6-Aug-15

Flow sensors emit minor levels of ultrasonic energy

Doc Num: SUM-003-03_v3 (ENG)

Page: 11 of 33

6.4 Gas Measurement System (M4 Monitors Only) Mount the gas measurement module using the pole clamp in the orientation shown. Use flexible gas tubing to connect the gas supply from the gas blender to the gas measurement module. Also use flexible gas tubing to connect from the gas measurement module to the oxygenator gas inlet port. Position the Gas Measurement Module between the Gas Blender and the Oxygenator. It is recommended that an anti- bacterial filter is positioned between the Gas Measurement Module and the Oxygenator. To Oxygenator Adjuster Knob Connect to oxygenator gas outlet port

From blender

For electrical connections, see section 3.

If the optional support arm is being used, attach the arm to a suitable pole. Then clamp the sensor by gently tightening the lever. By loosening the adjuster knob (pictured Left) will allow all joints to become loose. Manoeuvre the sensor into position such that the tube indicated in the picture left attaches to the oxygenator exhaust port. Once a good position is found tighten the adjuster knob and the assembly will become rigid. Sensor outlet port (Connect gas scavenger line here)

Position the exit CO2 near the oxygenator gas exit port and use a flexible tube to connect the exit CO2 sensor to the oxygenator gas outlet port. Try to maintain a slight gradient in the tube such that the sensor is lower than the oxygenator exhaust port, this will enable any water to run through the sensor. However keep the sensor electrical cables pointing upwards (as shown in picture above) to stop water condensation from entering the sensor. If a gas scavenge line is to be used the scavenge line should be vented and attached to the exhaust sensor outlet port.

Warning: The prediction of PO2 and PCO2 by the M4 will remain within specified levels of accuracy providing re-synchronization with an arterial blood gas sample occurs on a regular basis i.e. 24 hours or less due to changes in oxygenator efficiencies. Ensure the gas module and exhaust sensor are mounted as shown in the above pictures. After use, purge the gas flow airline with air to prolong servicing intervals. The gas module has been design to operate with Air, Oxygen, Nitrogen, CO 2, and the Anaesthetic gases Sevoflurane, Isoflurane and Desflurane. Do not block nor restrict the sensor outlet port under any circumstances. The gas module should not be pressure tested by any other means other than by using the Spectrum Pressure Test Kit (3003-030-101)

Date:6-Aug-15

Doc Num: SUM-003-03_v3 (ENG)

Page: 12 of 33

Main User Controls Power On / Power Off: Power On:

Press the flashing blue power button and wait 45 seconds for system to become operational.

Power Down

Press the blue power button then confirm yes in the dialog box.

The monitor should remain connected to mains electricity to ensure the back–up battery remains fully charged. In this condition the power button will flash intermittently. Alarm Mute Button

Main Screen Layout (M4 shown for illustration purposes)

Press to activate and deactivate mute function

Graph line Identifiers

Configurable Gauges

Main Record button Visible only when sensor is fitted. (Page 14)

Session Details Setup screens for monitor And measurements (Pages 15, 16 & 17)

Graph Controls

(Page 14)

(Page 14)

Status Bar (Page 19)

Screen Dimming Button Touching the main screen or activation of an alarm will return the screen to full brightness

Date:6-Aug-15

Doc Num: SUM-003-03_v3 (ENG)

Time / Date Axis

Page: 13 of 33

Start, Pause & Stop Functions To commence monitoring press the Record button, the Record button will change to Stop. Press the Stop button and then select Yes from the pop up box to stop the current session. The Stop button will change to Clear. If No is selected from the pop up the session will continue.

Press the Stop button and select Pause from the pop up to suspend the current session. The Stop button will change to Resume and flash. Press the Resume button again and the session will continue. Pressing the Clear button will delete current session data from the active memory but not the SD card. The Clear button will change to Record.

Graph Controls Pressing the Zoom button will change the graph horizontal scale from a range of 1 minute to 1 day. Actual scale will be displayed in the status indicator field. Pressing the Left button will allow the user to review graphical data, the graph will move left by scale set from Zoom as above. The Continue button will flash to indicate that the graph is no longer displaying real-time graphical data. Press the Continue button to return graph to real-time trending.

Details Screen Press the “Details” button on the main menu to enter patient and case related information. Patient:

Allows the user to enter the patient name which will be displayed on the graph

Weight:

Patient weight can be entered which will allow cardiac index to be calculated

BSA:

Patient Body Surface Area (BSA) can be entered which will allow cardiac index to be calculated

Procedure:

Up to 8 procedures can be entered and selected via the drop down menu

User Name:

Up to 8 user names can be entered and selected via the drop down menu

Date:6-Aug-15

Doc Num: SUM-003-03_v3 (ENG)

Page: 14 of 33

Setup sub screen Press the “Setup” button from the main screen and this will take you to a sub screen with the following additional buttons. Press the Service button and a keyboard will be displayed where passwords can be entered to access administration pages. Press the Medical Physics button and information about the software versions, voltages and temperatures of the unit, unit serial number and some other medical physics functions are displayed. Press the Machine Config button and various configuration settings are displayed for the monitor, see section below for further details. Press the Gauge Config button to gain access to the gauge configuration utility for setting gauge positions, colours and measurements. See section below for further details Press the Graph Config button to gain access to the graph configuration utility for setting number of graphs, measurements to be displayed and graph line colours, see section below for further details. The session must be recording for this button to be available. Pressing the Capture button will simultaneously select all the capture buttons of all available measurement channels that have a Capture, Sync to feature. Once the capture button has been pressed it will change to display Clear Capture Once any of the measurement page Sync To buttons are pressed and data is entered, a 1 minute timer will start to count down on the Clear Capture button. If another Sync To is performed on one of the other pages, the timer is reset back to 1 minute. If the timer gets to zero the captured values are discarded. Press the Show Spectra button and a graph showing the absorbance data for both the Arterial and Venous SO2 measurements is displayed. This can be used to detect broken fibre optic cables. Press the OK button and the main screen will be shown.

Medical Physics page

Unit serial number Machine Voltages and temperatures. Note: this has multiple pages denoted by the 1/3 at the bottom

Any machine errors are logged and can be exported to an SD card and sent to Spectrum Medical for decoding

Software versions and sensor details Note: this has multiple pages denoted by the 1/11 at the bottom

Date:6-Aug-15

This OK button when pressed takes the user back to the setup page

Doc Num: SUM-003-03_v3 (ENG)

Page: 15 of 33

Machine Configuration page Press the Setup button on the main menu and then press the Machine Config button. Screen Brightness:

Press the + or - buttons to adjust screen brightness. To activate the screen dimming function the brightness setting must be set to less than 100%. This will cause the Dim button on the main screen to appear.

Auto Dim:

Select Yes from the pop up box to activate auto-dim. The auto-dim function will dim the LCD when the monitor is running in battery mode.

Volume Setting:

Press the + or - buttons to change alarm volume. After adjustment the monitor will sound to indicate the selected audio level.

Date & Time:

To adjust date and time, first highlight the appropriate field, and then use the up or down arrows to modify numbers.

Logging Interval:

Sets the recording frequency of high resolution data to the SD Card.

Language:

Sets the text language that is displayed to user on all user pages.

Gauge Configuration The main screen can be configured to display active gauge information in either a horizontal format (single row) or a horizontal and vertical format (column and row). To access the gauge configuration screen press the Setup and then press the Gauge Config button.

Step 1

To configure parameters for gauge display first press the Green “+” button, select from the list of available parameters (as displayed in the pop up box) and press Ok to close.

Step 2

Configure each individual parameter for colour. Units values are displayed for information purposes only.

Step 3

To activate the vertical display press the side gauge On button.

Step 4

To assign a parameter to a gauge position the user will need to first select the gauge field and then select the parameter from the parameter table. To deselect the parameter from a gauge position, first select the gauge field and then deselect from the table.

Date:6-Aug-15

Doc Num: SUM-003-03_v3 (ENG)

Page: 16 of 33

Graph Configuration The main screen can be configured to display trending information a single graph format or upper and lower graph format. To access the graph configuration screen, press the Setup button and then press the Graph Config button. Step 1

To configure parameters for graphing first press the Green + button, select from the list of available parameters ( as displayed in the dialog box) and press Ok to close.

Step 2

Configure each individual parameter for colour and graphing range limits. Unit values are displayed for information purposes only.

Step 3

Press the Upper Graph button, then select parameters from the parameters table to be displayed. De-selection will remove parameters from the graphical display.

Step 4

If a dual graph display format is required press Lower Graph button, then again select parameters for display. De-selection will remove parameters from the graphical display, complete de-selection of Lower Graph parameters will revert the display to a single graphing format.

Parameter Configuration Press the Setup button on the main menu to access the parameter configuration page. Parameter navigation is achieved by pressing a displayed digital gauge. Function availability is parameter dependent. A description of available functions is as follows:Label:

To rename a gauge description from its default settings press the label field. Using the keypad enter new name and press OK to close.

Units:

If units can be changed they will be shown as black text, if not they will be greyed out.

Capture:

Press an active Capture button (indicated with bold text) to capture a system reference for later comparison with a blood gas sample.

Sync To:

To synchronise the monitor with a blood gas value press the “active” Sync To (indicated by bold text) button. Using the numeric keypad enter the B.G.A. value and press OK to close. Capture / Sync To parameters are: SaO2, SvO2, Hb, Hct, PO2 and PCO2

Alarm Limits:

Use the “+” or “–“ buttons to adjust alarm Limits.

Factory Reset: Pressing Factory Reset will return the parameter reference back to the factory calibration.

Date:6-Aug-15

Doc Num: SUM-003-03_v3 (ENG)

Page: 17 of 33

Gas and Fluid Flow Configuration Additional fluid and gas flow functions to those listed above:Set Zero:

To optimize absolute flow measurement press the Set Zero button to zero flow readings during circuit set up. Only use the Set Zero button when flow is static; this feature is enabled when flow is less than 10% of a sensors flow range.

Equalise Flow: To optimize the differential flow measurement, press the Equalize Flow button when the fluid is flowing unrestricted in both sides of the circuit and when it is at the optimal Cardiac Index. (Only available for fluid flow) Invert Flow:

Invert flow allows the user to change the direction of flow measurement.

PO2 and PCO2 Additional features to the basic set above:-

Temperature Source:

Pressing this button on any of the PO2 or PCO2 setup pages will allow the selection of either the live sensor reading or a fixed value of 37 °C as the temperature source for the PO2 and PO2 calculations.

Warning: An accurate value for the blood temperature is essential for the accurate estimation of PO2 and PCO2. The Fixed 37°C option must only be used when the temperature of the blood leaving the oxygenator is known to be 37°C. If the blood temperature can vary away from 37°C a blood temperature probe must be fitted to the gas module and selected here for correct operation.

Cardiac Index Entering the patient’s height and weight on the Details page allows for the cardiac index to be displayed. The setup page for cardiac index allows the user to change the channel label and the alarm limits only.

Date:6-Aug-15

Doc Num: SUM-003-03_v3 (ENG)

Page: 18 of 33

Emboli Setup To setup the emboli alarm press Setup then a Flow gauge then Emboli Volume. Label:

To rename a gauge description from its default settings press the label field. Using the keypad enter new name and press OK to close.

Alarm Limits Enabled:

Changing this to YES enables emboli alarm setting to NO disables emboli alarm.

Upper alarm:

Use the “+” or “–“ buttons to adjust alarm Limits.

If activated the emboli detection system will audio alarm and the flow channel will flash red with Emboli Alarm. Emboli Total Count and Emboli Total Volume pages allow the user to reset the count or volume to zero by pressing the set zero button.

O2 and CO2 sensor calibration It is recommended that the O2 and CO2 sensors are calibrated once every three months. Press setup then the FiO2 gauge and press the Sync 2 button. This will display the live O2 and CO2 values and the values to be synchronised to. Follow the on screen instruction ensuring the exhaust sensor is connected via a short gas tube to the gas module. Apply a flow of 100% O2 through both the gas module and exhaust CO2 sensor for at least 8 minutes. Monitor the live reading on the pop up and when readings stabilize press the Sync To button at the bottom. This will perform the synchronization. Then press the return key to return to the setup page.

Status Bar The status indicator bar will report the following conditions: 1) 2) 3) 4) 5) 6)

Battery, Mains Power & Charging Status Sizing of Connected Sensors (as shown in tubing I.D. and Wall Thickness) Available SD Memory (will only indicate when SD is inserted into the monitor) Over Heating Function (will display an icon if the unit is getting too hot) External communications status Graph x axis scale 3

Date:6-Aug-15

2

Doc Num: SUM-003-03_v3 (ENG)

1

4

5

Page: 19 of 33

6

Backup battery The monitor incorporates a backup battery which will allow up to 15 minutes’ operation in the event of a mains failure. The monitor may optionally be supplied with an additional battery pack (fitted to the rear of the machine) which allows up to one hour’s operation without mains power. The time of operation on battery will vary depending on the number of sensors and other accessories in use. The battery will take typically two hours to fully re-charge. It is recommended that the monitor be left connected to the mains when not in use, to ensure that the battery is fully charged when needed.

When a mains failure occurs, a dialog box will appear:

Touch OK and the dialog box will disappear. The dialog box will also disappear when the mains supply is restored.

A dialog box will appear when the monitor is operating on battery and there is approximately 5 minutes’ battery life remaining: Touch OK and the dialog box will disappear. The dialog box will also disappear when the mains supply is restored.

When the battery is completely depleted the monitor will shut down with no further warning.

Recording of data and Total loss of power The device incorporates the facility to record data to a SD memory card that can be reviewed when required. The recording of data will commence from the time you press the record button provided an SD card is inserted. If an SD Card Is not present when recording commences only data from the time the SD card is inserted will be stored on that card. Data stored to the SD Card is retained when the unit is powered off. In the event the unit suddenly powers off whilst recording to an SD Card, the data recorded up to that point is retained. The SD card is not required for the monitor to function, if the device is operated without the SD memory card, data will not be stored when the device is shut down or total power loss occurs.

Date:6-Aug-15

Doc Num: SUM-003-03_v3 (ENG)

Page: 20 of 33