Stryker

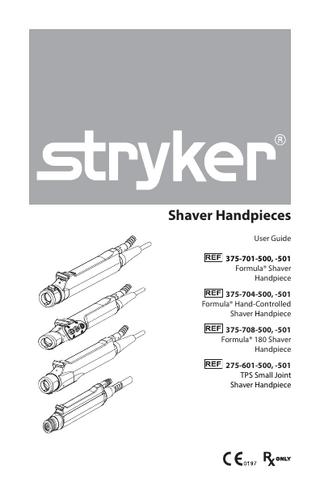

Formula Shaver Handpieces User Guide Ref 375-701,704,708 and 275-601 Oct 2012

User Guide

32 Pages

Preview

Page 1

Table of Contents Warnings and Cautions ...3 Product Description/Intended Use ...6 Indications and Contraindications ...9 Setup and Connection ...10 Operating the Handpiece ...13 Cleaning and Sterilization ...17 Periodic Maintenance Schedule ...27 Troubleshooting ...28 Technical Specifications ...29 Symbols ...31

Warnings and Cautions Warnings To avoid potential serious injury to the user and the patient ent ntt aan and/ and/or damage to this device, the user must obey the following warnings: ngs

Prior to Surgery • •

•

• •

Federal law (United States of America) restricts cts these devices i to use by, b or on order of, a physician. To avoid potential serious injury to the user and patient and/or damage to these devices, read this user guide and the user guides for other components, namely the console, the footswitch, and the cutting blade thoroughly and be familiar with its contents prior to using this equipment. Before using the handpieces in a surgical procedure, inspect it for any damage. Ensure that there are no loose or missing components and that all parts move freely. Do not use the equipment if damage is apparent. Set up the entire system and verify each function before introducing a handpiece to the surgical site. Clean and sterilize the handpiece prior to the first use and every use thereafter.

During Surgery •

•

•

The handpieces are designed to be used by a qualified physician familiar with arthroscopic procedures. Misusing the handpieces may cause damage to both the patient and system components. The handpieces generate electronic noise that may interfere with EKG readings. Should EKG readings become erratic while a handpiece is in use, power down the handpiece before reacting to the EKG reading, to ensure the electronic interference is not causing inaccurate EKG readings. Do not operate the handpiece unless the shaver blade is immersed in solution and suction is activated (at least 5 in. Hg). Failure to do so may result in abnormal wear of the cutting surfaces, overheating, particulate generation, and accumulation of unwanted materials in the surgical site. EN-3

•

• • •

•

•

•

•

•

Do not bend shaver blades or use them for prying. Excessive pressure on them may cause it to break and may cause harm to the patient and operating-room staff. Broken pieces may also enter the surgical site, where they will be difficult to remove. Running arthroscopic shaver blades at speeds greater than 6000 RPM may result in particulate generation. To avoid possible user injury, never attempt to change the blade while the handpiece is running. For Formula® handpieces use only Formula® arthroscopic shaver blades (375-XXX-XXX, 380-XXX-XXX, 385-XXX-XXX) and Crossfire™ Xtreme arthroscopic shaver blades (475-XXX-XXX, 480-XXX-XXX, and 485-XXXXXX). Using unapproved blades may cause unexpected results. For a complete list of shaver blades, contact your Stryker representative or Stryker customer service. For TPS Small Joint handpiece, use only small joint shaver blades (275627-000, 275-637-000, 275-628-000, 275-628-000, 275-641-000, 275647-000, 275-831-000). Using unapproved shaver blades may cause unexpected results. For a complete list of shaver blades, contact your Stryker representative or Stryker customer service. Do not modify shaver blades in any way. Modifying shaver blades may cause product damage and personal injury to the patient and operating-room staff. Broken pieces may also enter the surgical site, where they will be difficult to remove. Avoid contacting shaver blades with metal objects. Do not insert metal objects in the shaver blade window. If shaver blades contact metal objects, they may break, leaving pieces in the surgical site where they will be difficult to remove. Do not use this device in the presence of flammable anaesthetics, other flammable gases or objects, near flammable fluids such as skin prepping agents and tinctures, or oxidizing agents. Observe appropriate fire precautions at all times. Do not use this device in oxygen-enriched atmospheres, nitrous oxide (N2O) atmospheres, or in the presence of other oxidizing agents, to prevent risk of explosion. Ensure that oxygen connections are not leaking.

After Surgery •

EN-4

Reprocess device(s) as soon as reasonably practical following use.

Cautions To avoid potential damage to this device, please note the following cautions: • • • • •

Carefully unpack the unit and check if any damage occurred during shipment. If damage is detected, do not use the equipment. Test this equipment for functionality prior to a surgical procedure. This unit was fully tested at the factory before shipment. Attempt no internal repairs or adjustments not specifically detailed in this user guide. Doing so may cause damage to the device. Pay close attention to the care and cleaning instructions in this user guide. A deviation may cause damage. Read the entire user guide before assembling or connecting the unit.

Cable •

•

Do not thread or twist the cable connector for insertion or removal. It is a push/pull connector and may be damaged by twisting it into or out of place. To avoid damaging the cable, grasp only the knurled portion of the cable connector when connecting or disconnecting the cable. Never pull on the cord itself.

Shaver • •

•

Do not stall the handpiece. Doing so may damage the motor. Always install the soaking cap for the Formula® handpieces prior to cleaning or sterilization. If moisture reaches the connection pins of the cable connector, it could damage the connector. Do not immerse the handpiece when it is hot. This may damage the handpiece.

EN-5

Product Description/Intended Use The shaver handpiece is an electrically powered, hand-held surgical instrument that uses interchangeable shaver blades to abrade and remove bone and accomplish the debridement of soft tissue. The shaver handpiece features a quick-locking mechanism for easy blade insertion and removal, and a suction irrigation port for removing irrigant from the operating site. The handpiece is avaliable in the following models: Model

Part Number

Operated by

Formula® Shaver handpiece

375-701-500

Compatible footswitches

(with non-ratcheting suction)

(375-701-501)

Formula® Hand-Controlled Shaver handpiece

375-704-500

(with non-ratcheting suction)

(375-704-501)

Formula® 180 Shaver handpiece

375-708-500

(with non-ratcheting suction)

(375-708-501)

TPS Small Joint Shaver handpiece

275-601-500

Hand controls located on the shaver body or by compatible footswitches Hand controls located on the shaver body or by compatible footswitches Compatible footswitches

Note: •

The Formula® Shaver handpiece is identical to the hand-controlled model with exception of the control buttons.

•

The Formula® 180 Shaver button function is identical to the Formula® Hand-Controlled Shaver, even though the button locations are different.

•

Formula® and TPS Small Joint Shaver handpieces are only compatible with Stryker shaver systems and footswitches.

Formula® Handpieces Formula® handpieces also feature a blade-recognition system that eliminates the need for manually entering blade information and cutting speeds into the console. As blades are inserted into the Formula® handpiece, the handpiece identifies the blade and automatically selects the optimal cutting speed and direction. EN-6

Formula® Handpiece Features 1

4

3

2

5 6 7 8

9 Figure 1: Formula® Hand Controlled Shaver Handpiece

1. Suction control lever

Adjusts suction flow between high and low settings

2. Suction tubing connector

Connects to suction tubing to provide irrigation outflow

3. Handpiece cable

Connects the handpiece to the shaver console

4. Quick-release button

Releases blades from the handpiece

5. Button I

Activates the handpiece (or performs a programmable function)

6. Button II

Selects between the forward, reverse, and oscillate mode (or performs a programmable function)

7. Button III

Selects between forward and reverse when the handpiece is in the forward, or reverse mode (or performs a programmable function)

8. Cable connector

Connects to the shaver console port

9. Soaking cap

Protects the cable connector during sterilization

EN-7

TPS Small Joint Shaver Handpiece The TPS Small Joint Shaver handpiece is a smaller and lighter handpiece designed for small joint applications.

TPS Small Joint Shaver Handpiece Features 1

2

3

4 1. Suction control lever

Adjusts suction flow between high and low settings

2. Suction tubing connector

Connects to suction tubing to provide irrigation outflow

3. Handpiece cable

Connects the handpiece to the shaver console

4. Locking collar

Releases blades from the handpiece

EN-8

Indications and Contraindications Indications The shaver handpiece is indicated to be used by surgeons in orthropedic surgery for the resection of tissue and burring of bone. The shaver handpiece is indicated for use in the following orthopedic joints: •

Knee

•

Shoulder

•

Ankle

•

Elbow

•

Wrist

•

Hip

•

Temporomandibular

Examples of uses of the product include the resection of torn knee cartilage, subacromial decompression, resection of synovial tissue in other joints, and where the surgeon deems appropriate.

Contraindications There are no known contraindications.

EN-9

Setup and Connection Before setting up the handpiece, ensure the console and footswitch have been set up properly. See the Total Performance System (TPS), Crossfire™ , or Consolidated Operating Room Equipment (CORE) user guide for console setup instructions. See the TPS, Crossfire™, and iSwitch® footswitch user guide for footswitch setup instructions. English Only

TPS

5100-001-709

Español Deutsch Français Italiano Nederlands 5100-001-712

Dansk Suomi Norsk Svenska Português

Polski Ελληνικά

한국어

5100-001-733 5100-001-750 (does not include Norsk)

5400-050-716

5400-050-734

日本語 中文简体

5100-001-720 (does not include 한국어)

CORE

5400-050-700

5400-050-754

Crossfire™

1000-401-036

P11344

iSwitch®

1000-400-700

1000-400-700

5400-050-724

Setup Summary To set up the handpiece, perform the following steps: 1. Connect handpiece to the shaver console. 2. Install and remove shaver blade into/from the handpiece. 3. Connect suction tubing to the handpiece.

Connecting the Handpiece to the Shaver Console 1. Align the red dot on the cable connector with the red dot on the console cable ports. 2. Gently push the cable connector into the port, as shown below. It will lock in place (See Figure 2). (To disconnect the cable, grasp the cable connector and pull back on the connector collar.)

Figure 2: Crossfire™ console

EN-10

3. If applicable, press the “OK” button on the shaver console warning screen. The default home screen will appear.

Installing and Removing Shaver Blade • Warning

•

Do not bend shaver blades or use them for prying. Excessive pressure on them may cause it to break and may cause harm to the patient and operating-room staff. Broken pieces may also enter the surgical site, where they will be difficult to remove. Avoid contacting shaver blades with metal objects. Do not insert metal objects in the shaver blade window. If shaver blades contact metal objects, they may break, leaving pieces in the surgical site where they will be difficult to remove.

Formula® Handpieces 1. Align the locking guides on the base of the shaver blade with the locking guides on the handpiece, as shown below.

2. Slide the blade into the handpiece until it locks into place. 3. Gently tug the blade to ensure that it is engaged. 4. To remove a blade, press the quick-release button on the handpiece (A) and withdraw the blade (B), as shown below.

B

A

EN-11

TPS Small Joint Shaver Handpiece 1. Push down on the locking collar (A) of the handpiece, as shown below. A

2. Gently insert the shaver blade. A slight rotating motion will help properly seat the blade. 3. Release the locking collar. 4. Pull the installed shaver blade slightly to ensure that it is engaged. 5. To remove a shaver blade, push down on the locking collar of the handpiece and lift the shaver blade out of the handpiece.

Connecting Suction Tubing to the Handpiece 1. Connect a suction tube to the suction-tubing connector (A) on the handpiece, as shown below. The tube should overlap all of the ridges on the connector. A

2. Gently tug on the suction tube to ensure it is firmly connected to the handpiece. 3. Set the suction to the desired level.

EN-12

Operating the Handpiece Before operating the handpiece, ensure the console and handpiece have been set up properly. For handpiece setup instructions, see the “Setup and Connection” section of this user guide. For console setup instructions, see the TPS, CORE, or Crossfire™ console user guide.

Operation Summary Operating the handpiece involves the following activities: 1. Selecting the appropriate blade settings on the console 2. Selecting cutting direction and speed 3. Controlling the handpiece with footswitch or handpiece 4. Controlling the suction with the suction-control lever

Selecting the Blade Settings Blades are intended to move in different directions and speeds. When modifying blade settings, observe the following guidelines: •

Arthroscopic cutter blades are most effective at resecting soft tissue in oscillation mode.

•

Arthroscopic burs are most effective in the forward mode.

Formula® Handpieces The Formula® handpieces automatically selects the optimal blade settings for any blade inserted into the handpiece. When a blade is inserted into the handpiece, its name and optimal cutting speed appear on the console screen.

TPS Small Joint Shaver Handpiece Set the handpiece speed and mode with the touch screen on the console or footswitch.

EN-13

Selecting the Cutting Direction and Speed Selecting any of the direction or cutting speed can be accomplished by using the footswitch, handpieces, or console. The handpieces offers three basic cutting directions: •

Forward

•

Reverse

•

Oscillate

In the forward and reverse directions, the handpiece also offers two preset cutting speeds: •

High

•

Low

For details on the footswitch, handpiece, or console control settings please refer to appropriate console user guide.

Controlling the Handpiece Footswitch Control The handpieces can be controlled using the footswitch. Please refer to the appropriate footswitch and/or console user guide for control settings.

Figure 3: Crossfire™ footswitch

Note: The footswitch pedals may be reprogrammed to better suit user preferences. For details, see the appropriate console user guide. EN-14

Handswitch Control The Formula® 180 and Formula® Hand-Controlled Shaver handpieces can also be controlled by three built-in buttons near the blade end of the handpiece, as shown below. The buttons and their default settings are described below.

1 2 3

1. Button I (Gray)

Activates the handpiece in the direction and mode selected on the console screen

2. Button II (Yellow)

Selects between oscillate mode and forward/ reverse mode

3. Button III (Blue)

Selects between forward and reverse when the handpiece is in forward/reverse mode

Note: •

Pressing any one of the three buttons while the handpiece is running will deactivate the handpiece.

•

The hand-control buttons may be reprogrammed to better suit user preferences. For details, see the appropriate console user guide.

EN-15

Controlling the Suction

Warning

Do not operate the handpiece unless the shaver blade is immersed in solution and suction is activated (at least 5 in. Hg). Failure to do so may result in abnormal wear of the cutting surfaces, overheating, particulate generation, and accumulation of unwanted materials in the surgical site.

Use the suction-control lever to regulate suction, as shown below: •

To increase suction, push the lever toward the blade end of the handpiece.

•

To decrease suction, pull the lever toward the handpiece body, as shown below. Increase

EN-16

Decrease

Cleaning and Sterilization These reprocessing instructions are provided in accordance with AAMI ST79, AAMI ST81, AAMI TIR12, ISO 17664, and ISO 17665. While they have been validated by Stryker as being capable of preparing the device for re-use, it remains the responsibility of the processor to ensure that the reprocessing, as actually performed (using equipment, materials, and personnel in the reprocessing facility), achieves the desired result. This normally requires validation and routine monitoring of the process. Stryker recommends users observe these standards when reprocessing medical devices. • Warning

• •

To minimize the risk of infection, clean and sterilize the handpiece prior to the first use and every use thereafter. Ensure the suction lever is completely in the on position during sterilization. Drying time depends on several variables, including: altitude, humidity, type of wrap, preconditioning, size of chamber, mass of load, material of load, and placement in chamber. Users must verify that drying time set in their autoclave yields dry surgical equipment.

Cautions •

•

•

•

For Formula® handpieces, always install the soaking cap prior to cleaning or sterilization. If moisture reaches the connection pins of the cable connector, it could damage the connector. Never immerse the handpiece in a liquid to help it cool after sterilization, or product damage may result. Cool the handpiece by wrapping it in a sterilized damp sponge or cloth. Do not cross-sterilize the handpiece. Alternating between different methods of sterilization may cause undue wear on the handpiece. Product longevity is extended by the consistent use of a single sterilization method. Do not leave the handpiece in solutions longer than necessary. This may accelerate normal product aging.

Limits on Reprocessing • •

Proper processing has a minimal effect on the handpiece. End of life is normally determined by wear and damage due to use. Damage incurred by improper processing will not be covered by the warranty. EN-17

Cleaning Point of Use

• •

Wipe excess soil from the handpiece using disposable paper towels. If an automated cleaning method will be used, rinse the handpiece in sterile distilled water immediately after use.

Containment and Transportation

Reprocess device(s) as soon as reasonably practical following use.

Preparation for Cleaning

1.

2.

Disassemble the handpiece from the other system components. •

Disconnect the handpiece from the console.

•

Remove the blade from the handpiece.

•

Dispose of all used blades according to hospital regulations.

Attach the soaking cap to the cable connector, for Formula® handpieces. •

EN-18

Twist the cap onto the connector, as shown below.

Manual Cleaning

1. Wipe Wipe excess soil from the handpiece with disposable paper towels. 2. Soak in Enzymatic Detergent •

Prepare an enzymatic detergent solution1 with lukewarm tap water, according to manufacturer’s recommendations.

•

Wipe the entire surface of the handpiece using a soft clean cloth dipped in the detergent solution.

•

Immerse the handpiece in the detergent solution, ensuring the solution contacts all inner and outer surfaces of the handpiece. Use a syringe to inject lumens with a minimum of 50mL of solution.

•

Soak the handpiece in the solution for a minimum of 15 minutes.

3. Brush

1

Cleaning was validated using Enzol® at 1 oz/gal. at 35-40°C.

•

Thoroughly brush the exterior of the handpiece, including mated and rough surfaces, with a softbristled brush.

•

Brush around all movable parts, including the suction valve, while moving them through all extreme positions, as shown below.

•

Inject all lumens, crevices, and mated surfaces at least five times with a minimum of 50mL of detergent solution.

•

With the handpiece immersed in the detergent, thoroughly brush the interior and exterior with an appropriately sized soft-bristled brush. (Note: An appropriately sized brush for the interior of the handpiece will be a bottle brush with bristles that extend the diameter of the handpiece lumen.) Brush the handpiece lumens while actuating the suction lever through its extreme positions. EN-19

4. Rinse •

Remove the handpiece from the detergent solution and rinse it with water2 at ambient temperature until all visible detergent residue is removed.

•

Flush all lumens, crevices, and mated surfaces at least five times with a minimum of 50mL of water.

•

After all detergent residues are removed, rinse the handpiece for an additional 30 seconds.

•

Drain any excess water from the handpiece by holding it at an incline.

5. Soak in Non-Enzymatic Detergent •

Prepare a non-enzymatic detergent solution3 in lukewarm tap water according to manufacturer’s recommendations.

•

Immerse the handpiece in the detergent solution, ensuring the solution contacts all inner and outer surfaces of the handpiece. Use a syringe to inject lumens with a minimum of 50mL of solution.

•

Soak the handpiece in the solution for a minimum of 15 minutes.

6. Brush

2

Cleaning was validated using reverse osmosis deionized (RO/DI) water.

3

Cleaning was validated using RenuKlenz™ at ¼ oz/gal. at 35-40°C.

EN-20

•

Thoroughly brush the exterior of the handpiece, including mated and rough surfaces, with a softbristled brush.

•

Brush around all movable parts, including the suction valve, while moving them through all extreme positions, as shown below.

•

Inject all lumens, crevices, and mated surfaces at least five times with a minimum of 50mL of detergent solution.

•

With the handpiece immersed in the detergent, thoroughly brush the interior and exterior with an appropriately sized soft-bristled brush. (Note: An appropriately sized brush for the interior of the handpiece will be a bottle brush with bristles that extend the diameter of the handpiece lumen.) Brush the handpiece lumens while actuating the suction lever through its extreme positions.

7. Rinse •

Remove the handpiece from the detergent solution and rinse it with water4 at ambient temperature until all visible detergent residue is removed.

•

Flush all lumens, crevices, and mated surfaces at least five times with a minimum of 50mL of water.

•

After all detergent residues are removed, rinse the handpiece for an additional 30 seconds.

•

Drain any excess water from the handpiece by holding it at an incline.

8. Dry Dry the handpiece using a clean cloth. Filtered pressurized air5 can be used to assist drying. 9. Inspect 4

Cleaning was validated using reverse osmosis deionized (RO/DI) water.

•

Visually inspect the handpiece, including all internal surfaces, for remaining soil. Use an endoscopic camera and endoscope if necessary to see the inner surface of the lumen.

•

If soil remains, repeat the manual cleaning procedure, focusing on those areas.

5

Drying was validated with pressurized air at 20 psi.

EN-21