Instruction for Use

40 Pages

Preview

Page 1

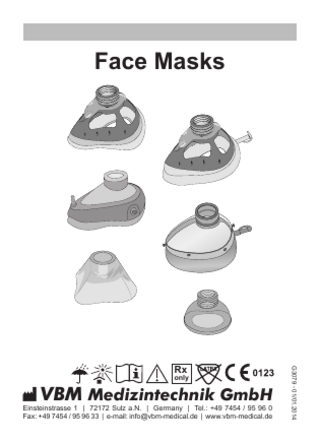

Face Masks

only

VBM Medizintechnik GmbH

Einsteinstrasse 1 | 72172 Sulz a.N. | Germany | Tel.: +49 7454 / 95 96 0 Fax: +49 7454 / 95 96 33 | e-mail: info@vbm-medical.de | www.vbm-medical.de

G3079 - 01/01.2014

Rx

Optional

1

Optional

1

2

2

3

3

5 4

4

English Intended use / Indication During manual or mechanical ventilation, the mask is used to seal off the mouth and nose area. Contraindications In patients who do not have an empty stomach and with increased risk of aspiration, mask ventilation must not be employed except in emergency situations. Safety information -- The device may only be used by medical personnel. -- Insufficient ventilation can lead to permanent damage in patients. -- Press the mask onto the face of the patient forming a good seal. If the seal is not tight, the ventilation may be affected. -- Extend the head back so that the airways remain patent! In case of cervical spine injuries, weigh up whether or not the head should be extended back. -- If ventilation is not possible with this device, another adequate type of ventilation must be initiated. Use 1. Select the appropriate mask size (see table). 2. Press the mask to the face of the patient forming a good seal. Mask with inflatable cushion: if necessary, inflate or deflate the cushion using a syringe. 3. Hold the mask with the hand. Option: fix the mask with a harness and hook ring. Summary table Size 0 1 2 3 Size 2 3 4 5 6

Mask without colour coding Rendell Baker Masks Newborn Infant Child, small Child

Pediatric masks, round Newborn Infant Child -

Mask with colour coding Child Adult, small Adult, medium Adult, large Adult, extra large

Colour coding green yellow red purple blue

REPROCESSING (CLEANING, DISINFECTION, STERILISATION) GENERAL INFORMATION • The reusable devices are supplied non-sterile and must be unpacked, cleaned, disinfected and sterilised prior to first use. • Devices must be reprocessed prior to each use. • The manufacturer is not responsible for damage resulting from improper reprocessing. • The user is obliged to validate their procedures or the devices and accessories and to comply with the validated parameters during every reprocessing. • It is recommended to use an automated procedure because automated cleaning and disinfection are significantly more effective. • The effectiveness has been verified by an independent and accredited test laboratory. • To achieve effective reprocessing, heavy soiling must not be allowed to dry on the device and must be removed immediately after use. • Silicone devices must not come into contact with oil and grease.

7

CLEANING / DISINFECTION Automatic Cleaning / Disinfection Notes regarding the use of washer disinfectors • Use deionised water. Notes regarding the use of cleaning agents and disinfectants • When alkaline cleaning agents are used, the agent must be subsequently neutralised. • Do not use drying agents. Procedure validated by the manufacturer: 1. If the product consists of several parts, disassemble the product as shown in the sketch (page 2). 2. Only for inflatable cushion: To prevent penetration of fluid close the cushion with the plug. 3. Place the products into the injector carriage: Product / Items Positioning in the injector carriage Hook ring (1), connector (2) and pins (5) Mesh tray (securing with a cover net) Dome (3), cushion (4) and masks made of Injector jets one piece 4. Start programme with the following parameters: a. Pre-rinse with deionised water at 20 °C (68 °F) with an exposure time of 1 min. b. Clean at 55 °C (131 °F) with an exposure time of 5 min. using deionised water and Sekumatic® ProClean cleaning agent (dose: 0.5 % (5 ml/l)). c. Neutralise with Sekumatic® FNZ at 20 °C (68 °F) with an exposure time of 2 min. (dose: 0.1 % (1 ml/l)). d. Rinse with deionised water at 20 °C (68 °F) with an exposure time of 2 min. e. Thermal disinfection at 93 °C (199 °F) for 5 min. with deionised water. f. Dry at 100 °C (212 °F). 5. Check for visible contamination. If necessary repeat the reprocessing. 6. All parts must be dry and free from damage (cracks, ruptures etc.). Assemble the product as shown in the sketch (page 2). 7. Check the devices according to the section ‘Checks’ and prepare them for sterilisation (see section ‘Packaging’). Manual Cleaning / Disinfection Notes regarding the use of cleaning agents and disinfectants • Prepare the cleaning and disinfection solutions prior to each manual cycle. • Use deionised water. Procedure validated by the manufacturer: 1. If the product consists of several parts, disassemble the product as shown in the sketch (page 2). 2. Only for inflatable cushion: To prevent penetration of fluid close the cushion with the plug. 3. Prepare a 2 % (30 ml/l) cleaning and disinfection solution of Sekusept® Aktiv with deionised water at 20 °C (68 °F). After 15 min the cleaning and disinfection solution can be used. 4. Clean the devices with soft sponges in the cleaning and disinfection solution. Areas difficult to access must be cleaned with soft brushes. Hard brushes and other materials which may damage the silicone cuff or the silicone surface of the devices must not be used. 5. Place the devices into the cleaning and disinfection solution and leave for 15 min. Ensure all internal cavities are covered with solution. 6. Remove cleaning and disinfection solution by rinsing thoroughly with deionised water. Remaining residues can shorten the device life span or can lead to material damage. 7. Dry the devices. Avoid any accumulation of water. 8. Check for visible contamination. If necessary repeat the reprocessing. 9. All parts must be dry and free from damage (cracks, ruptures etc.). Assemble the product as shown in the sketch (page 2). 10. Check the devices according to the section ‘Checks’ and prepare them for sterilisation (see section ‘Packaging’).

8

CHECKS After disinfection and before every use, the devices must be visually inspected for damage (cracks, breakages, etc.). The inflatable cushion must be inflated with a syringe and checked for leaks. Damaged or leaky devices must not be reused. PACKAGING • Sterilise only the assembled product. • Only for inflatable cushion: open the plug of the cushion. After the cleaning and disinfection procedure, the devices must be packed into a package that is suitable for steam sterilisation (according to the currently valid versions of DIN EN 868 and DIN EN ISO 11607). STERILISATION Notes regarding sterilisation: • Devices or sterilisation packages must be protected from mechanical damage. Sterilisation validated by the manufacturer: • The devices must be steam sterilised using a fractional vacuum process. • Exposure time is 5 min. with a sterilisation temperature of 134 °C (273 °F). REUSABILITY The end of the life span for reusable devices is basically determined by wear and damage caused by its use. Considering the maximum life span of 5 years, reusable devices can be reprocessed up to 100 times if used properly and if the cleaning, disinfection and sterilisation instructions are complied with. Every further reuse is the responsibility of the user (see section „Checks“). Warning By using the devices on patients with suspected prion disease there may be a high risk of transmission. In such case the doctor must decide whether the device is either disposed of (see section ‘Disposal’) or reprocessed according to national directives. STORAGE CONDITIONS Considering the maximum life span of 5 years, the device can be stored in its original packaging under the following conditions: • Protect from heat and store in a dry place. • Protect from sunlight and sources of heat. • Do not store silicone devices together with devices made of PVC or rubber. SERVICE Prior to the return of medical devices for complaints/repairs, the devices must have run through the complete reprocessing process to exclude any risk for the staff of the manufacturer. For safety reasons the manufacturer preserves the right to refuse soiled or contaminated devices. DISPOSAL Used or damaged devices must be disposed of in accordance with the relevant national and international legal regulations.

9