VIASYS Healthcare

Vyaire Low and High Flow MicroBlenders Instruction Manual Ver A May 2021

Instructions Manual

29 Pages

Preview

Page 1

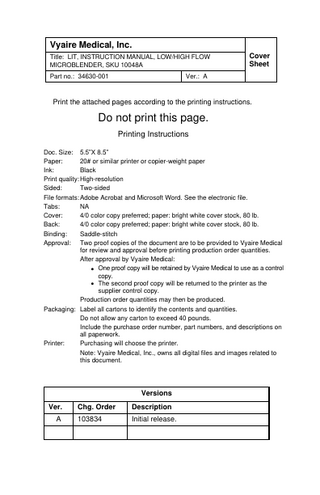

Vyaire Medical, Inc. Title: LIT, INSTRUCTION MANUAL, LOW/HIGH FLOW MICROBLENDER, SKU 10048A Part no.: 34630-001

Cover Sheet

Ver.: A

Print the attached pages according to the printing instructions.

Do not print this page. Printing Instructions Doc. Size: 5.5”X 8.5” Paper: 20# or similar printer or copier-weight paper Ink: Black Print quality: High-resolution Sided: Two-sided File formats: Adobe Acrobat and Microsoft Word. See the electronic file. Tabs: NA Cover: 4/0 color copy preferred; paper: bright white cover stock, 80 lb. Back: 4/0 color copy preferred; paper: bright white cover stock, 80 lb. Binding: Saddle-stitch Approval: Two proof copies of the document are to be provided to Vyaire Medical for review and approval before printing production order quantities. After approval by Vyaire Medical: • One proof copy will be retained by Vyaire Medical to use as a control copy. • The second proof copy will be returned to the printer as the supplier control copy. Production order quantities may then be produced. Packaging: Label all cartons to identify the contents and quantities. Do not allow any carton to exceed 40 pounds. Include the purchase order number, part numbers, and descriptions on all paperwork. Printer: Purchasing will choose the printer. Note: Vyaire Medical, Inc., owns all digital files and images related to this document.

Versions Ver. A

Chg. Order

Description

103834

Initial release.

Low Flow MicroBlender and High Flow MicroBlender Instruction Manual

34630-001 Version A (2021-05)

MicroBlender Instruction Manual

This document is protected by United States and International Copyright laws. This document may not be copied, reproduced, translated, stored in a retrieval system, transmitted in any form, or reduced to any electronic medium or machine-readable form, in whole or in part, without the written permission of Vyaire. Information in this document is subject to change without notice. This document is for informational purposes only and should not be considered as replacing or supplementing the terms and conditions of the License Agreement. © 2021 Vyaire. Vyaire, the Vyaire Logo and all other trademarks or registered trademarks are property of Vyaire Medical, Inc., or one of its affiliates. Manufactured By Vyaire Medical, Inc. 26125 North Riverwoods Blvd Mettawa, IL 60045 USA 1-833-327-3284 [email protected] www.vyaire.com

Customer and Clinical Support Product, Accessories, and Parts Ordering 1-833-327-3284 [email protected]

The symbols defined below may appear in this document and on the equipment label or labels.

General warning Caution Medical device manufacturer

IPX-0

Ingress protection marking Attention, consult accompanying documents

NOTE

Provides additional information to clarify an explanation or instruction. Do Not Throw in Trash Humidity Limitation Storage Temperature Limit Serial Number Date of Manufacture

ii

34630-001 Version A (2021-05)

MicroBlender Instruction Manual

Contents Low Flow MicroBlender and High Flow MicroBlender ... i Instruction Manual ... ii Section 1: Introduction ... 1 Section 2: Operation Overview ... 2 Gas Inlets ... 2 Balance Module ... 3 Proportioning Module ... 3 Alarm/Bypass ... 4 Outlet Ports... 5 Bleed Outlet ... 5 Section 3: Warnings, Cautions, and Notes... 6 Section 4: Controls and Alarms ... 8 Section 5: Performance Checks ... 9 MicroBlender Alarm / Bypass Check Reverse Flow Check ... 9 Reverse Flow Check ... 10 Section 6: Troubleshooting Guide ... 11 Section 7: Cleaning and Sterilizing ... 13 Section 8: Maintenance and Service ... 14 Section 9: Parts and Accessories ... 15 Section 10:

Explanation of Abbreviations ... 16

Section 11:

Specifications ... 19

Section 12:

Warranty ... 22

34630-001 Version A (2021-05)

iii

MicroBlender Instruction Manual Intended Use The Vyaire MicroBlender products provide an accurate air/oxygen mixture of gas directly to a patient by way of a mask or cannulas or to a ventilator for subsequent delivery to the patient. They are used to treat patients who suffer a wide array of diseases and clinical conditions among the neonatal, pediatric, and adult patient populations that require the use of supplemental oxygen. MicroBlenders alone do not come into contact with any human tissues or bodily fluids, but oxygen delivery devices such as a mask, nasal cannula, or endotracheal tube that are used in conjunction with blenders do. MicroBlenders are intended to be used in hospital/clinical settings operated by trained medical/clinical personnel.

iv

34630-001 Version A (2021-05)

MicroBlender Instruction Manual

Section 1:

Introduction

The MicroBlender is a lightweight, compact, air-oxygen blender that provides precise mixing of medical-grade air and oxygen. The MicroBlender provides oxygen concentrations from two gas-outlet ports.

Low Flow MicroBlender

High Flow MicroBlender

The MicroBlender can be used in conjunction with: •

Oxygen hoods

•

Resuscitation bags

•

Masks

•

Transports

•

Nasal cannulas

•

Treatments

34630-001 Version A (2021-05)

1

MicroBlender Instruction Manual

Section 2:

Operation Overview

The MicroBlender provides selection of oxygen concentrations by means of a single control knob located on the front of the unit. Oxygen concentrations ranging from 21 to 100% are available. Outlet Flow Range Bleed Flow Low Flow MicroBlender

Primary, Left Side

3-30 LPM

No Bleed Flow

Auxiliary, Right Side

0-30 LPM

2.5-3.5 LPM

High Flow MicroBlender

Primary, Bottom

15-120 LPM

No Bleed Flow

Auxiliary, Right Side

2-100 LPM

10-12 LPM

Auxiliary Outlet

Primary Outlet

Low Flow MicroBlender Outlets

Auxiliary Outlet Primary Outlet High Flow MicroBlender Outlets Gas Inlets The ports located on either side of the unit allow flexibility for the clinician. The MicroBlender operates by using two 30–75 PSI gas sources that enter the device through DISS or NIST connectors located on the bottom the unit.

2

34630-001 Version A (2021-05)

MicroBlender Instruction Manual

Air and oxygen hoses are connected directly onto the MicroBlender gas inlets.

30 - 75 PSI Inlet Connectors Each inlet connector incorporates a 30 micron particulate filter. After passing through the filter, the gases travel through duckbill check valves that prevent reverse gas flow from either the air or oxygen supply systems.

30 - 75 PSI Inlet Connectors The MicroBlender is tested for compliance with ISO 11195E (1995), clause 6, regarding reverse-gas flow as delivered. Balance Module The gases then enter the balance modules, which equalize the operating pressures of the air and oxygen. The diaphragm in the balance module responds to a difference in pressure and directs the movement (stroke) of each poppet contained within the air and oxygen chambers. The movement of each poppet adjusts the amount of gas fl owing through the balance module, equalizing the air and oxygen pressures. Proportioning Module From the balance module, the gases flow into the proportioning module and mix according to the oxygen percentage selected with the MicroBlender control knob. This module consists of a double-ended poppet positioned between two valve seats.

34630-001 Version A (2021-05)

3

MicroBlender Instruction Manual One valve seat controls the passage of air and the other valve seat controls the passage of oxygen into the MicroBlender outlets. At this point, the two gases have been blended according to the oxygen percentage selected by the control knob. Alarm/Bypass The alarm feature provides for an audible alarm if source pressures differ by 20 ±2 PSI or more. The primary purpose of the alarm is to audibly warn the operator of an excessive pressure drop or depletion of either source gas. The alarm will also activate when there is an elevation of either source gas resulting in a 20 ±2 PSI difference. Should both gas pressures (oxygen or medical air) increase or decrease simultaneously, and a 20 ±2 PSI differential is not seen, there will not be an audible alarm. If either source gas pressure drops, the output pressure of the blender will drop similarly, since the source gases are always balanced to that of the lower pressure. The bypass function operates in unison with the alarm. The alarm bypass poppet communicates directly with the air supply on one end and the oxygen supply on the other. When the two source gases are near equal in pressure, the alarm bypass poppet is positioned over the bypass channel, blocking the flow of both gases. The poppet will remain seated for unequal pressures up to 20 ±2 PSI. Once a 20 ±2 PSI difference occurs, the higher gas pressure will overcome the spring force and pressure of the poppet at its opposite end, thus creating a path (air or oxygen) to flow into the alarm channel. The gas with the higher pressure will also flow directly to the blender outlet port bypassing the Balance and Proportioning Modules. The gas is also directed to the bottom of the unit to the reed alarm, thus creating an audible warning. The oxygen concentration will be that of the gas at the higher pressure. The blender in the alarm/bypass mode will deliver the oxygen (100%) or medical air (21%) until the pressure has been restored to a differential of approximately 6 PSI. If the blender is set at 21% and the OXYGEN source pressure is reduced enough to produce a 20 ±2 PSI or greater differential, the unit may not alarm because it will continue to deliver 21% concentration according to the setting. If the control is moved slightly from the 21% setting, the alarm will sound. Similarly, if the blender is set to deliver 100% concentration and AIR source pressure is reduced or lost, the unit may not alarm because it will continue to deliver the selected 100% concentration. If the blender is left connected to source gases but is not being used (i.e., no output flow or bleed flow) the unit will not alarm if a 20 ±2 PSI or greater pressure differential develops. If the blender is not in use, an alarm under these conditions will be an unnecessary distraction or nuisance.

4

34630-001 Version A (2021-05)

MicroBlender Instruction Manual Outlet Ports On the Low Flow MicroBlender, two outlet ports are located on the right and left sides of the MicroBlender and allow low ranges from 0-30 LPM with bleed and 3 - 30 LPM without bleed respectively. On the High Flow MicroBlender, the primary outlet port is located on the bottom of the MicroBlender, and the auxiliary outlet is located on the right side of the MicroBlender, allowing ranges from 15 to 120 LPM without bleed and 2 to 90 LPM with bleed respectively. Bleed Outlet For the Low Flow MicroBlender, when a connection is made to the right side outlet port, for example, when a flow meter is attached, a bleed flow of 2.53.5 LPM is achieved. For the High Flow MicroBlender, when a connection is made to the right side outlet port, a bleed flow of 10-12 LPM is achieved. For both Blenders, the bleed flow exits the unit through a muffler port located on the bottom of the MicroBlender.

High Flow MicroBlender

34630-001 Version A (2021-05)

5

MicroBlender Instruction Manual

Section 3:

Warnings, Cautions, and Notes

The MicroBlender should be operated by trained, qualified medical personnel under the direct supervision of a licensed physician. Before clinical application, the following WARNINGS, CAUTIONS and NOTES should be read and understood. Note: Notes provide additional information to clarify an explanation or instruction. Caution Cautions identify conditions or practices that could result in damage to the MicroBlender or other equipment. Warning Warnings identify conditions or practices that could result in serious adverse reactions or potential safety hazards. NOTE Users are advised to use inlet pressure regulators with the MicroBlender to display system pressure. Allow equilibration time for FiO2 changes before analyzing gas.

CAUTIONS •

•

6

Always operate air/oxygen blenders with clean and dry medical grade gasses. Contaminant or moisture can cause defective operation. Air used for medical purposes must meet USP compressed air and/or ANSI Z86.1 1973 grade F, and water vapor content must not exceed a blender’s dew point of 5°F below the lowest ambient temperature to which the delivery system is exposed. Particulate content must not exceed that which would be downstream of a 15 micron absolute filter. Water vapor content of medical air or O2 supply to the MicroBlender must not exceed 5.63 grams H2O per cubic meter of non-condensable gas.

34630-001 Version A (2021-05)

MicroBlender Instruction Manual WARNINGS •

•

• • • • • • • • •

If either the air or oxygen gas source fails, the MicroBlender alarm sounds, alerting the clinician that a condition has occurred that may significantly alter the FiO2 and flow output from the MicroBlender. If either the air or oxygen gas source pressure is reduced or increased creating a pressure differential of 20 ±2 PSI, the MicroBlender alarm sounds. This condition significantly alters the FiO2 and flow output from the MicroBlender. Always operate the MicroBlender with clean and dry medical grade gases. Air Inlet Filter/Water Trap (P/N 07426) is recommended for use with the MicroBlender. The patient gas must be monitored with an oxygen analyzer. DO NOT steam clean, autoclave, or otherwise subject the MicroBlender to temperatures above 145°F (62°C). DO NOT immerse the assembled MicroBlender in liquid decontamination agents. Consult a physician for appropriate FiO2 setting. DO NOT tape, obstruct, or remove the reed alarm outlet at any time. DO NOT occlude or obstruct the bleed port or muffler on the bottom of the MicroBlender. Adjustment of the oxygen concentration must be verified using an oxygen analyzer.

The following symbol may be referenced on the blender or in the accompanying documentation. Symbol

Source/Compliance

Meaning

Symbol #03-02 IEC 60878

Indicates ATTENTION, consult ACCOMPANYING DOCUMENTS

34630-001 Version A (2021-05)

7

MicroBlender Instruction Manual

Section 4:

Controls and Alarms

The MicroBlender delivers selected oxygen concentrations through two outlet ports. The outlet ports, although similar in appearance, have different flow range specifications. The two outlet ports provide a choice of flow ranges based on the application desired. Both outlets may be used simultaneously, provided the combined flows do not exceed the rated maximum flow capability of the MicroBlender. The use of a flow meter attached to either or both of the outlet ports may be used to control the flow of mixed gas. Control knob-allows selection of oxygen concentrations from 21 to 100%

Low Flow MicroBlender

High Flow MicroBlender (Front View)

An audible alarm indicates a differential of 20 PSI has been reached between air and oxygen inlet gas pressures.

8

34630-001 Version A (2021-05)

MicroBlender Instruction Manual

Section 5:

Performance Checks

Before placing the MicroBlender into clinical use, perform the following performance checks. WARNING If the MicroBlender does not function as described below, contact Vyaire (refer to the company information at the beginning of this manual). DO NOT use the MicroBlender until correct performance is verified.

MicroBlender Alarm / Bypass Check Reverse Flow Check Adjustment Response 1. Connect the 50 ±5 PSIG** air/ oxygen source gases. Adjust the control knob to 60%. Connect the flow meter to the auxiliary outlet and set the flow to 2 LPM.

1. Alarm/Bypass* should not activate (if gases are within 20 PSI of each other).

2. Disconnect the 50 PSIG air source from the MicroBlender.

2. Audible alarm, bypass* gas flow starts.

3. Reconnect the 50 PSIG** air source to the MicroBlender.

3. Audible alarm stops; bypass* gas flow stops flowing.

4. Disconnect the 50 PSIG** oxygen source from the MicroBlender.

4. Audible alarm, bypass* gas flow starts.

5. Reconnect the 50 PSIG** oxygen source to the MicroBlender.

5. Audible alarm stops; bypass* gas flow stops flowing.

6. Verify that the oxygen flow meter is set at 2 LPM.

6. Oxygen analyzer should read 60 ±3% when measured from the flow meter outlet.

*Bypass flow should occur whenever the alarm sounds, but this condition can only be verified by measuring O2 concentrations with an oxygen analyzer. **Gas supply pressures of 50 PSIG provide optimal performance.

34630-001 Version A (2021-05)

9

MicroBlender Instruction Manual Reverse Flow Check

1. 2.

3.

4. 5.

10

Connect both gas supply hoses to the inlet connectors. Connect the oxygen hose to an oxygen pressure regulator, and submerge the free end of the air hose in a container of water. Do not make a connection to either blender outlet (so that they remain closed). Slowly adjust the oxygen pressure regulator to increase pressure from 0 to 50 PSIG* while looking for bubbles to rise from the submerged air hose connector. The presence of bubbles indicates leakage of the one-way valve and the need for repair. If there is no leakage, disconnect the oxygen from the regulator and submerge the end of the hose in water. Connect the air hose to an air pressure regulator and repeat the procedure. Repair if bubbles are present. *Gas supply pressures of 50 PSIG provide optimal performance.

34630-001 Version A (2021-05)

MicroBlender Instruction Manual

Section 6:

Troubleshooting Guide

Problem

Potential Cause

Corrective Action

Oxygen concentration discrepancy between MicroBlender settings and analyzer.

1. Analyzer out of calibration.

1. Calibrate the analyzer

2. Flow requirements are below the specified LPM range.

2. Correct the flow. Verify that the correct outlet port is being used. Each outlet port has a different flow range.

3. Gas supply is contaminated.

3. Correct the contaminated gas supply. If repair is needed, contact Vyaire

4. MicroBlender is out of calibration.

4. Contact Vyaire for repair.

5. Bleed filter is obstructed, causing reduction of bleed.

5. Contact Vyaire

6. Air entrained into circuit by ventilator or accessory device.

6. Correct

1. Inlet pressure difference greater than 20 PSI.

1. Correct the pressure difference.

2. Alarm module is not calibrated properly.

2. Contact Vyaire for repair.

3. Inlet gas contamination, alarm module malfunction.

3. Contact Vyaire for repair.

Reed plate improperly installed or damaged.

Contact Vyaire for repair.

Alarm sounding

MicroBlender in bypass - no alarm.

34630-001 Version A (2021-05)

11

MicroBlender Instruction Manual

12

Problem

Potential Cause

Corrective Action

MicroBlender is accurate only when inlet gas pressures are equal.

1. Balance module not functioning properly.

1. Contact Vyaire for repair.

2. Both air and oxygen gas sources are below 30 PSIG.

2. Correct the low pressure condition.

34630-001 Version A (2021-05)

MicroBlender Instruction Manual

Section 7:

Cleaning

•

Use 17.2% isopropanol disposable wipes (CaviWipes™ towelettes) to clean the exterior surfaces. Allow the surfaces to dry before using the device.

•

Do not steam autoclave or otherwise subject the MicroBlender to temperatures over 145°F.

•

Do not immerse the assembled Low Flow MicroBlender in liquid decontamination agents.

•

Do not use any strong solvent cleaners on labels or markings.

34630-001 Version A (2021-05)

13

MicroBlender Instruction Manual

Section 8:

Maintenance and Service

CAUTION The MicroBlender should only be serviced or calibrated by a Vyaire trained technician. Vyaire equipment is designed to provide the maximum amount of utilization with a minimum amount of maintenance. When determining the desired frequency of complete overhaul intervals, three variables must be considered: •

Frequency of use

•

Cleanliness of compressed air source

•

Use of an air inlet filter/water trap

The MicroBlender, like other pieces of health care equipment, will require routine maintenance over a period of time. Before to placing the MicroBlender into clinical use, follow the performance-check guidelines outlined in Section 5. When using the MicroBlender with a compressed air source, an air inlet filter/water trap (P/N 07426 or equal) is recommended. Contaminants from hospital air lines may compromise the function of the MicroBlender. CAUTION If the MicroBlender does not function as outlined in Section 5, contact Vyaire for service. Applicable parts used in the MicroBlender have been cleaned and de-greased for oxygen service. All lubricants used during assembly are designed for use in an oxygen enriched environment. Use only Vyaire specified lubricants when servicing this device. Elastomer components, such as diaphragms and O-rings, are designed to function satisfactorily for a minimum of two years. The need for cleaning and replacement depends on gas line conditions and is indicated by the MicroBlender not meeting its specified performance.

14

34630-001 Version A (2021-05)

MicroBlender Instruction Manual

Section 9:

Parts and Accessories

Parts and Accessories MicroBlender Brackets Part No.

Description

04322

Pole Mount 1 w/ Female Dovetail

05141

Dovetail Bracket, Accepts Built -in Bracket

05213

Dovetail Bracket, Wall Mount Female

09437

Rail Mount Adapter Bracket

Optional Accessories Part No.

Description

30086-001

Oxygen Supply Hose, 3 m

30087-001

Oxygen Supply Hose, 1 m

25541-001

Air Supply Hose, 3 m

30088-001

Air Supply Hose, 1 m

07426

Air Inlet Filter/Water Trap

34630-001 Version A (2021-05)

15