8 Pages

Preview

Page 1

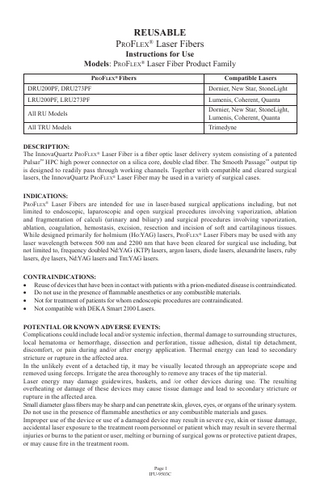

REUSABLE ProFlex® Laser Fibers

Instructions for Use Models: ProFlex® Laser Fiber Product Family ProFlex® Fibers

Compatible Lasers

DRU200PF, DRU273PF

Dornier, New Star, StoneLight

LRU200PF, LRU273PF

Lumenis, Coherent, Quanta

All RU Models

Dornier, New Star, StoneLight, Lumenis, Coherent, Quanta

All TRU Models

Trimedyne

DESCRIPTION: The InnovaQuartz ProFlex® Laser Fiber is a fiber optic laser delivery system consisting of a patented Pulsar™ HPC high power connector on a silica core, double clad fiber. The Smooth Passage™ output tip is designed to readily pass through working channels. Together with compatible and cleared surgical lasers, the InnovaQuartz ProFlex® Laser Fiber may be used in a variety of surgical cases. INDICATIONS: ProFlex® Laser Fibers are intended for use in laser-based surgical applications including, but not limited to endoscopic, laparoscopic and open surgical procedures involving vaporization, ablation and fragmentation of calculi (urinary and biliary) and surgical procedures involving vaporization, ablation, coagulation, hemostasis, excision, resection and incision of soft and cartilaginous tissues. While designed primarily for holmium (Ho:YAG) lasers, ProFlex® Laser Fibers may be used with any laser wavelength between 500 nm and 2200 nm that have been cleared for surgical use including, but not limited to, frequency doubled Nd:YAG (KTP) lasers, argon lasers, diode lasers, alexandrite lasers, ruby lasers, dye lasers, Nd:YAG lasers and Tm:YAG lasers. CONTRAINDICATIONS: • Reuse of devices that have been in contact with patients with a prion-mediated disease is contraindicated. • Do not use in the presence of flammable anesthetics or any combustible materials. • Not for treatment of patients for whom endoscopic procedures are contraindicated. • Not compatible with DEKA Smart 2100 Lasers. POTENTIAL OR KNOWN ADVERSE EVENTS: Complications could include local and/or systemic infection, thermal damage to surrounding structures, local hematoma or hemorrhage, dissection and perforation, tissue adhesion, distal tip detachment, discomfort, or pain during and/or after energy application. Thermal energy can lead to secondary stricture or rupture in the affected area. In the unlikely event of a detached tip, it may be visually located through an appropriate scope and removed using forceps. Irrigate the area thoroughly to remove any traces of the tip material. Laser energy may damage guidewires, baskets, and /or other devices during use. The resulting overheating or damage of these devices may cause tissue damage and lead to secondary stricture or rupture in the affected area. Small diameter glass fibers may be sharp and can penetrate skin, gloves, eyes, or organs of the urinary system. Do not use in the presence of flammable anesthetics or any combustible materials and gases. Improper use of the device or use of a damaged device may result in severe eye, skin or tissue damage, accidental laser exposure to the treatment room personnel or patient which may result in severe thermal injuries or burns to the patient or user, melting or burning of surgical gowns or protective patient drapes, or may cause fire in the treatment room.

Page 1 IFU-9503C

PRECAUTIONS: • INCREASED LASER EXPOSURE TIME WILL RESULT IN A DEEPER AND WIDER ZONE OF TISSUE NECROSIS! • Do not bend fiber at sharp angles which can occur when handling the laser fiber, during insertion or removal from the endoscope / cystoscope, or when the endoscope / cystoscope is flexed at an angle that exceeds the permissible bend angle of the laser fiber. If visible (aiming beam) light can be seen leaking from the fiber, fiber failure is likely to result when therapeutic energy is applied. • Immediately discontinue use if ‘light leaks’, breaks, or fractures appear in laser fiber. These breaks or fractures may allow undirected emission of laser energy, rendering the distal tip useless and potentially causing harm to surrounding tissues and persons. • If tissue appears to be stuck to the lasing tip, carefully remove the tip from the tissue and control for hemorrhage and/or tissue lesion. Immediate action might have to be taken. For the fiber, use a soft, sterile cloth to clean the debris from the glass tip, taking care to avoid side pressure that may damage the tip. • Severe impacts or side stresses may fracture the glass tip. • The time and energy required for treating a specific target area may be different when using the InnovaQuartz ProFlex® Laser Fiber compared to using other fibers. • During each lasing interval, it is helpful to move the distal tip up and back 1 mm to 2 mm to prevent the tip from sticking to tissue. • ALWAYS wear appropriate protective eyewear during the delivery of laser energy as described in the laser system manual. Ensure that the patient and the procedure room personnel wear appropriate protective eyewear during the delivery of laser energy as failure to do so may result in injury. • Read all instructions thoroughly before use. HOW SUPPLIED AND STORED: This InnovaQuartz ProFlex® Laser Fiber is supplied sterile. • Reusable: Reusable devices are A LIMITED REUSE PRODUCT, REUSABLE UP TO 5 TIMES (5X) BUT NOT INTENDED FOR INDEFINITE REUSE. • Sterility for the first use is guaranteed only if the original shipping package is not opened or damaged. • Store in a cool (27.5°C maximum), dry place for shelf life marked on the product label. • As supplied, shelf life is limited; expiration is marked on the product label. CAUTION: Federal (U.S.A.) law restricts this device to sale by, or on the order of, a physician. INSTRUCTIONS FOR USE: Prepare the Fiber for Use 1. Review the laser system manual for instructions, set-up and operation prior to activation of the laser. 2. Employ aseptic technique to ensure sterility when removing the product from the sterile pouch. Remove the device from the packaging by holding the connector and slowly pulling the fiber out of the hoop. Do not reuse the plastic packaging. 3. Ensure that the laser generator is in “OFF” or in “STANDBY” mode before attaching the laser fiber at the laser aperture (e.g. SMA port). 4. Remove the protective cap from the connector. Inspect the input under 20X magnification and if contaminated, wipe it clean with a sterile tissue. Attach the Pulsar™ fiber connector to the laser port and finger-tighten the connector nut to release interlock mechanisms. 5. The ProFlex® Laser Fiber optical conduit is glass and may be damaged if the fiber is bent sharply, struck or pinched. The output tip is unprotected by buffer and is the most delicate and easily damaged portion of the fiber. If the output tip is damaged, it may be stripped and cleaved using a sterile fiber stripper and sterile scoring wafer (supplied separately) using the instructions found on page 4. 6. Laser aperture is the fiber distal tip and is coincident with the aiming beam.

Page 2 IFU-9503C

Inspect the Fiber 1. Inspect the entire length of the fiber for breaks by first activating the laser aiming beam: breaks will appear as bright spots. Do not attempt to use a broken fiber. Reference FIGURE 1 below for examples of unacceptable spot checks after activating the aiming beam: FIGURE 1- Unacceptable Spot Checks

2. Inspect the working tip using the aiming beam output. With the tip about 5 cm (2 inches) from a light surface, the fiber is ready to use if the spot appears uniform and round. Non-uniform or distorted spots are indicative of a broken tip requiring repair. Reference FIGURE 2 below for an example of an acceptable fiber with a good working tip: FIGURE 2- Fiber With Good Working Tip Acceptable Spot Checks

Using the Fiber 1. In “STANDBY” mode, hold the fiber about 5 cm (2 inches) from the output or, if using an endoscopic device, carefully insert the fiber tip into the working channel and steadily pass it through the working channel in small increments so that the fiber is not bent or kinked, until the fiber tip is visible in the endoscope / cystoscope’s field of view and extends about 1 cm (0.4 inches) from the scope. 2. Adjust the laser output to a level appropriate for the intended use and not exceeding the fiber maximum approved power. (J X PPS = Watts, e.g. 0.8J @ 10pps = 8W). MAXIMUM POWER for ProFlex® Laser Fibers: 30W for ProFlex® 200 50W for ProFlex® 273 120W for ProFlex® 365, ProFlex® 550 and ProFlex® 1000 3. Using laser fibers in direct contact with target tissue greatly accelerates tip degradation; various techniques are being used and have been published. Techniques where fiber tips stand off target tissue, e.g. “dusting” preserve the fiber tip. If the tip becomes degraded performance will diminish. Producing a freshly cleaved output will restore most of the fiber’s original performance, but the tip’s square corners will not pass working channels as easily as a fresh and original Smooth Passage™ tip. Sterile tools and proper technique (see instructions on the following page) are required for producing a safe and effective fiber tip. 4. If the tip accumulates debris, turn the laser to “STANDBY” mode and carefully wipe the tip with a sterile pad. DO NOT SCRAPE THE FIBER with instruments or the tip will be damaged and may detach when passing channels and in use. 5. Activating the laser with the laser fiber tip in the endoscope / cystoscope’s working channel will lead to damage of the scope. Page 3 IFU-9503C

GUIDE TO PRODUCING A SAFE AND EFFECTIVE FIBER TIP: First Inspect the Fiber Tip • Before unnecessarily discarding a functional fiber tip it is advisable to inspect it for damage and debris. • With a minimum magnification of 20X, inspect the output tip for adhered tissue or other debris and if present, wipe the tip clean with a sterile gauze pad. • Degradation of the working tip is normal and will occur with prolonged use. • The fiber may be reprocessed intraoperatively or discarded if coating damage is detected or if the fiber has pits, cracks, chips or if intractable debris is present. Intraoperative Reprocessing of the Fiber Tip The recommended tools for stripping fibers are available through your authorized ProFlex® distributor or directly from InnovaQuartz. Check with your sales representative for additional information. Carefully follow the instructions for use. The following tools are recommended for stripping and cleaving ProFlex® Laser Fibers. Refer to the table below and use the blade colors as a guide. Ensure tools are sterile and maintained within the sterile field for intraoperative fiber repair. Autoclavable Stripping Tools Fiber Designation

Suggested PN

Buffer Guide (inches/microns)

Blade Color

200

BMS512S18FS

0.018 / 457.2

White

273

BMS514S18FS

0.021 / 533.4

Dark Green

365

BMS518S25FS

0.025 / 635.0

Yellow

550

BMS528S31FS

0.031 / 787.4

Black

1000

BMS544S55FS

0.063 / 1660.2

Brown

Autoclavable Cutting Tools For superior results, InnovaQuartz recommends using alumina scoring wafers (Part Number B38002IQ and B38012PF). Stripping the Buffer 1. Hold the stripping tool in one hand and the fiber in the other hand. Insert the fiber into the stripper through the buffer guide with the handles fully expanded until the fiber end aligns approximately with the 5 cm (2 inches) ruling on the handle. 2. If the fiber is difficult or impossible to insert through the buffer guide, double check the stripper blade color and guide number and cut about 2.5 cm (1 inch) from the end of the fiber and try again. 3. Firmly squeeze the stripper handles closed and hold them closed, then pull the fiber from the stripper as straight as possible.

Page 4 IFU-9503C

Test the Stripped Section for Damage (This test is CRITICAL for minimizing detached tip problems) Misaligned or damaged blades and poor technique may damage the fiber. This simple test can detect most such damage. 1. Ensure there are no sharp protrusions from the fiber tip first to avoid a puncture wound. 2. Hold the fiber near the end of the blue buffer, then place a finger of the other hand on the bare fiber tip and bend it to roughly 30 to 45 degrees off axis. Then rotate the fiber tip through at least one full circle while maintaining the bend in the fiber. Reference FIGURE 3 below for images of process: FIGURE 3 - Testing of Stripped Fiber Section:

3. If the fiber breaks, consider replacing the stripper. This challenge test will reveal any significant damage to the fiber within the future working tip length, but the test cannot be properly performed unless the instructions for stripping have also been carefully followed, i.e. approximately 5 cm (2 inches) of bare fiber is required to perform this test properly.

Page 5 IFU-9503C

Cleaving the Fiber 1. For best results, place the fiber on a clean, hard surface. The object of scoring the fiber is to just nick the glass cladding of the fiber: a 0.3 µm to 1.0 µm nick is optimal and such small nicks are difficult to achieve while holding the fiber in hand. ● Sharp Edge Cleaving Tool: Hold the fiber firmly in place on the blue buffer near the stripped section. Bring the blade straight down on the fiber, perpendicular to the fiber axis. Do not drag the blade across the fiber. Reference FIGURE 4 below for proper scoring angle. ● Square Edge Scoring Wafer: Hold the fiber firmly in place on the blue buffer near the stripped section. With the wafer perpendicular to the fiber axis, tilt the wafer so the smooth corner just touches the fiber, then drag gently across the fiber to produce a score line. Reference FIGURE 4 below for proper scoring angle. 2. A properly scored fiber will display a tiny leak when the fiber is illuminated with an aiming beam or other intense light source. 3. Pick the fiber up and hold it at the blue buffer in one hand. With the other hand, firmly grip the bare fiber section near the end (finger cots or rubber gloves aid in gaining purchase). Steadily pull the fiber about the score line or nick, without bending the fiber, until it breaks. FIGURE 4 - Scoring Angle: Sharp edge cleaving tool Square edge scoring wafer

Inspecting the New Tip 1. Connect the fiber to a laser or other intense light source (the surgical laser aiming beam will suffice) and hold the fiber tip approximately 5 cm (2 inches) from a lightly colored surface to project an output spot profile. 2. A well-defined circular spot indicates a clean cut. A slightly oval spot is generally acceptable but is not desirable. Non-uniform or distorted spots are unacceptable. Reference FIGURE 5 below for an example of an unacceptable spot checks after cleaving the fiber tip: FIGURE 5 - Unacceptable Spot Checks:

3. Oval spots result from non-orthogonal cut faces (bending the fiber about the score line) and nonuniform or distorted spots are caused by non-planar cut faces, chips or damage to the fiber core. If the cut is unacceptable, cut the fiber again until an acceptable cleave is produced.

Page 6 IFU-9503C

INSTRUCTIONS FOR REUSABLE DEVICES ONLY INSTRUCTIONS FOR REPROCESSING:

Manual Cleaning 1. Rinse the fiber thoroughly with warm potable tap water at 22°C to 40°C (71°F to 104°F). Remove any excess soil by wiping the fiber with a soft towel or gauze. 2. Soak the fiber for ten (10) minutes (minimum) in an enzymatic detergent solution. Follow manufacturer’s preparation directions for the detergent. 3. Use a clean, soft gauze pad or sponge soaked in the detergent solution to wipe the fiber from end to end to remove all residue. 4. Thoroughly rinse the fiber in warm potable tap water at 22°C to 40°C (71°F to 104°F) for a minimum of 30 seconds, to remove the cleaning solution and any loose residues. 5. Dry the fiber with a soft cloth or laboratory wipe and visually inspect for any remaining debris. 6. Repeat cleaning steps to remove any visual soil before proceeding to sterilization steps. Inspection 1. Inspect the fiber face at the distal (output) end with a microscope or endoscope with a video system (minimum magnification 20X). Slightly tilt the fiber face to view a variety of angles with light reflected from the fiber surface. Reprocess the distal tip as described on page 4, if needed. 2. The input fiber face should be free of any defects such as chips, cracks, scratches, pits, blemishes or debris. Using a fiber with visible defects at the laser connector may damage the laser system. IF DEFECTS ARE OBSERVED, DISPOSE OF FIBERS AS BIOHAZARDOUS WASTE.

STERILIZATION: • The fiber may be sterilized by steam. The fiber MUST be cleaned prior to sterilization. Optical fibers are glass and should be handled with care. The individual user must verify the actual sterility of reprocessed product prior to use. • Accelerated fiber aging in sterilization is directly proportional to the fiber coil diameter so LOOSELY COIL THE FIBER and place it in the largest available sterilization pouch and seal the pouch. Load pouches to allow room for circulation around the devices. • When sterilizing multiple instruments in one autoclave cycle, ensure the sterilizer’s maximum load is not exceeded. • Sterilize according to one of the protocols below: Gravity Displacement Temperature: 132°C to 134°C (270°F to 273°F) Exposure Time: 10 minutes Drying Time: 30 minutes

Gravity Displacement Temperature: 121°C to 123°C (250°F to 253°F) Exposure Time: 30 minutes Drying Time: 30 minutes

Page 7 IFU-9503C

Pre-Vacuum Temperature: 132°C to 134°C (270°F to 273°F) Exposure Time: 10 minutes Drying Time: 30 minutes

ProTrac is part of the ProFlex family of products. ProFlex, ProTrac, Pulsar and Smooth Passage are trademarks and/or registered trademarks of InnovaQuartz LLC. This product is protected by U.S. Patent No. 9,122,009 and/or 9,223,089. Bard and Advancing Lives and the Delivery of Healthcare are trademarks and/or registered trademarks of C. R. Bard, Inc. Copyright 2018 InnovaQuartz LLC.

Manufacturer: InnovaQuartz LLC 23030 N 15th Ave Phoenix, AZ 85027 Toll Free USA: 1-844-776-3539 (Pro-Flex) Outside USA: +001-623-434-1895 Info@ProFlexFibers.com

Page 8 IFU-9503C

Distributed by: C. R. Bard, Inc. Covington, GA 30014 USA 1-800-526-4455 www.bardmedical.com