ConMed

18 in. x 12 in. x 6 in. Sterilization Container, Hall Micro 100 System

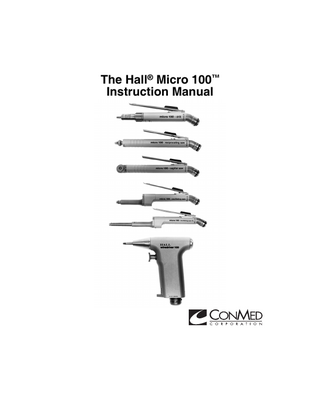

Hall Micro 100 Instruction Manual

44 Pages

Preview

Page 1

The Hall® Micro 100™ Instruction Manual

Proprietary Information This manual contains information deemed proprietary to ConMed Corporation. The information contained herein, including all of the designs and related materials, is the sole property of ConMed and/or its licensors. ConMed and/or its licensors reserve all patent, copyright and other proprietary rights to this document, including all design, manufacturing methodology and reproduction. This document, and any related materials, is confidential and is protected by copyright laws and shall not be duplicated, transmitted, transcribed, stored in a retrieval system, or translated into any human or computer language in any form or by any means, electronic, mechanical, magnetic, manual or otherwise, or disclosed to third parties, in whole or in part, without the prior express written consent of ConMed. ConMed reserves the right to revise this publication and to make changes from time to time in the contents hereof without obligation to notify any person of such revision or changes, unless otherwise required by law. The Hall Micro 100 is a trademark or registered trademark of ConMed Corporation.

ConMed Corporation 2012, 2014, 2015. All Rights Reserved.

Record the Model and Serial Numbers of the handpiece(s), and date received. Retain for future reference. Handpiece Model No.

Serial No

Date

Handpiece Model No.

Serial No

Date

Handpiece Model No.

Serial No

Date

Handpiece Model No.

Serial No

Date

Handpiece Model No.

Serial No

Date

Handpiece Model No.

Serial No

Date

Table of Contents

1.0

INTRODUCTION 1.1

Intended Use... 1

1.2

Operating Principle... 1

1.3

Warnings and Precautions... 1

1.4

2.0

Page

1.3.1

Warnings... 2

1.3.2

Precautions... 2

Symbol Definitions... 3

INSTALLATION AND OPERATION 2.1

Power Source and Regulator Installation and Operation... 5

2.2

Equipment Installation and Operation... 7

2.3

Micro 100 Drill (5053-009)... 10

2.4

2.3.1

Hall Bur Guard Assembly Instructions... 11

2.3.2

Assembly Instructions - Bur Guards... 12

2.3.3

Assembly Instructions - Laminectomy & Rhinoplasty... 13

2.3.4

Assembly Instructions - Angle Attachments... 15

2.3.5

Assembly Instructions - Contra-Angle Attachments... 16

Micro 100 Reciprocating Saw (5053-010)... 18 2.4.1

2.5

Micro 100 Sagittal Saw (5053-011)... 20 2.5.1

2.6

Blade Attachment... 20

Oscillating Saw (5053-012) and Oscillating Saw XL (5053-022)... 21 2.6.1

2.7

Blade Attachment... 19

Blade Attachment... 22

Wiredriver 100 (5053-013)... 23 2.7.1

Inserting Wires... 23

2.7.2

Wiredriver 100 Adaptor Chuck... 24

i

Table of Contents

3.0

MAINTENANCE 3.1

Cleaning and Sterilizing... 27 3.1.1

Cleaning Precautions... 27

3.1.2

Handpiece Cleaning Instructions... 28

3.1.3

Footswitch Cleaning Instructions... 29

3.1.4

Wiredriver 100 - Special Cleaning Instructions... 29

3.1.5

Attachment Lubricating Instructions... 30

3.1.6

Sterilization - Warnings, Precautions and Notes... 31

3.2

Troubleshooting... 32

3.3

Technical Specifications... 33

3.4

4.0

Page

3.3.1

Micro 100 Drill (5053-009)... 33

3.3.2

Micro 100 Reciprocating Saw (5053-010)... 33

3.3.3

Micro 100 Sagittal Saw (5053-011)... 33

3.3.4

Wiredriver 100 (5053-013)... 34

3.3.5

Micro 100 Oscillating (5053-012) and XL Oscillating Saws (5053-022). . . 34

3.3.6

Environmental Requirements... 34

Attachments and Accessories... 35 3.4.1

Micro 100 Handpieces... 35

3.4.2

Common Accessories for all Micro 100 Handpieces... 35

3.4.3

Additional Accessories for the Micro 100 Drill (5053-009)... 36

3.4.4

Additional Accessories for the Wiredriver 100 (5053-013)... 36

3.4.5

Miscellaneous Accessories... 36

CUSTOMER SERVICE 4.1

Assistance and Repair... 37

ii

1.0 INTRODUCTION It is recommended that personnel study this manual before attempting to operate, clean or sterilize the Hall® Micro 100™ Handpieces. The safe and effective use of this equipment requires the understanding of and compliance with all warnings, cautionary notices and instructions marked on the product and included in this manual.

1.1 Intended Use The Micro 100 System is designed for use in small bone surgeries. Each Micro 100 System handpiece is lightweight and perfectly balanced for better control, optimal feel and greater visibility during use, even in hard to reach surgical sites. A wide selection of cutting attachments completes the system for small bone procedures.

1.2 Operating Principle The Micro 100 Pneumatic Handpieces are powered by a source of compressed dry nitrogen to provide a pneumatic application of various mechanical forces depending on the handpiece. The handpieces may apply rotary, reciprocating, oscillating, sagittal or driving force, to the attachments and accessories for bone cutting, reaming, drilling, driving screws, sawing, and wire driving functions used in small bone surgical procedures or arthroplasties. Each Micro 100 Pneumatic Handpiece is controlled by an activation trigger or throttle lever and safety mechanism on the handpiece, or by using an optional footswitch.

1.3 Warnings and Precautions The words WARNING, PRECAUTION, and NOTE carry special meanings and they should be read carefully.

!

WARNING: The safety and/or health of the patient, user, or a third party is at risk. Comply with this warning to avoid injury to the patient, user, or third party. PRECAUTION: This contains information concerning the intended use of the device or accessory. Damage to the equipment is possible if these instructions are not followed. NOTE: A note is added to provide additional, focused, information. This equipment is designed for use by medical professionals completely familiar with the required techniques and instructions for use of the equipment. Read and follow all warning and cautionary notices and instructions marked on the product and included in this manual. Prior to using the device, read and follow all warning and precautionary notices and instructions marked on the product and included in this manual. Regular service is required to keep the Micro 100 handpieces at its optimum operating performance. See “Table 2: Maintenance Schedule” on page 26.

1

1.3.1 Warnings 1. Eye protection is always necessary when operating equipment. Eye injury may result without protection. 2. Prior to each use, perform the following:

!

• Inspect all equipment for proper operation. • Ensure all attachments, accessories and hoses are able to be correctly and completely attached to the handpiece. • Inspect pneumatic hoses for signs of wear or damage prior to use. Discontinue use and replace immediately if any signs of wear or damage are detected. • Check all equipment for any air or nitrogen leakage. If leakage is noticed, return for service. 3. Put the instrument in the “SAFE” position before changing burs, accessories or hoses, and when the instrument is not in use. Accidental activation of the instrument could cause injury. 4. Dull burs may cause heat build-up in the handpiece and the bone. It is recommended that single-use burs be used. 1.3.2 Precautions

!

1. Handpieces are factory sealed. Do not disassemble or lubricate, as this may void the warranty. There are no user-serviceable parts inside. 2. Use only ConMed and Hall accessories and attachments. 3. Handle all equipment carefully. Should a handpiece or attachment be dropped or damaged in any way, return it immediately for service. 4. Always use the proper bur guard, extension or attachment for the handpiece, as required, for the correct bur length and surgical procedure being performed. 5. Always inspect for bent, dull or damaged burs before each use. Do not attempt to straighten or sharpen. Do not use if damaged. After use, dispose of properly. 6. The ability to effectively clean and resterilize the single use devices has not been established and 2 subsequent re-use may adversely affect the performance, safety, and/or sterility of the device. 7. Continually check all parts of the instrument or its attachments for overheating. If overheating is noticed, discontinue use and return the equipment for service. 8. Do not use burs for plunge cutting. Damage or injury may occur. 9. Do not pressurize hose until all fittings have been connected and checked. 10. Do not move the foot control using the hose. Such action may cause damage to the fittings and/or hose 11. Do not restrict exhaust vents on hose, or severely bend or kink hose, or roll equipment over hose. Damage will occur. 12. Never operate the instrument above 100 psi (7 kg/cm2) dynamic pressure unless an extension hose is added to the standard 10 foot hose. Excessive pressure may cause damage to instrument and exert unusual stress on the hose. 13. The nitrogen regulator is for use with pneumatically powered surgical devices only. 14. After each use, thoroughly clean and sterilize the handpiece and accessories. (See “3.1 Cleaning and Sterilizing” on page 27).

STERILIZE

2

1.4 Symbol Definitions

!

Attention, consult accompanying documents.

Single Use Only.

Eye Protection Required. No user service recommended. Refer servicing to qualified ConMed service personnel.

Indicates product component should not be sterilized.

Indicates product component should not be immersed in any type of fluid.

Indicates handpiece should not be immersed in any fluid.

Indicates product should not be oiled or lubricated.

Not to be used for plunge cutting. Caution: Federal Law restricts this device to sale by or on the order of a physician. Non Sterile.

LOT

Lot Number.

3

Consult instructions for use.

Do not use if package is damaged.

Manufacturer.

REF EC REP

2

Catalog number.

Authorized representative in the european community. Do not resterilize.

STERILIZE

4

2.0 INSTALLATION AND OPERATION 2.1 Power Source and Regulator Installation and Operation WARNING: Nitrogen is not for inhalation. Does not support life. For use with powered surgical devices only. Research and experience have shown that water-pumped dry nitrogen is the ideal source for pneumaticallypowered surgical instruments. Water-pumped dry nitrogen is 99.97% pure, and will not support combustion or corrosion. Compressed dry nitrogen is recommended as the pneumatic power source. It is available in standard cylinders. Compressed dry nitrogen must meet the following specifications to ensure optimum safety for both patient and instrument. Nitrogen Content: 99.97% pure, dry nitrogen. Quality Assurance: To obtain the quality of gas needed, “water-pumped dry nitrogen, or liquid nitrogen, pumped dry” should be specified. Nitrogen is readily available from gas supply houses in H cylinders holding slightly more than 300 cubic feet (8.50 cubic meters). Initial set-up costs are relatively inexpensive as compared to compressed air. Nitrogen can be placed in the operating room or in a storage area and piped into the operating room. Manifold systems are available to eliminate frequent tank changes. PRECAUTION: Do not exceed 100 psi (7 kg/cm2) operating pressure unless a hose longer than the standard 10 ft. Universal Hose (5052-010) or extension hose is used. Add an additional 1 psi for every extra foot of hose. The Mirco 100 handpieces should be operated at 100 psi (7 kg/cm2) for maximum operating efficiency, and should be monitored by the operating pressure gauge of the regulator. Lower pressure setting can be set for lower speed and torque requirements. Pressure must be set with the instrument running to ensure proper operating pressure. Never start a procedure if the operating pressure gauge indicates less than 500 psi (35.1 kg/cm2) in the tank. Never run the tank pressure below 200 psi (14.0 kg/cm2). The tank should be thoroughly wiped off with disinfectant and draped prior to placement in the operating room. Always have the tank securely fastened to a stable object. 1. Prior to set-up in the operating room, open the tank valve (counterclockwise) slowly and allow enough gas to escape to blow out any debris that may have accumulated in the valve. Stay clear of the opening and the back of the tank during this procedure. Return the valve to the closed position.

5

2. Install the regulator with a 1 1/8 inch wrench, or adjustable wrench.

NOTE: The threaded adaptor of the nitrogen regulator is designed to fit nitrogen fittings only. Incompatibility of the regulator and tank indicates a gas source other than nitrogen or an improper regulator for use with a nitrogen tank. 3. Once the regulator is securely installed, ensure the regulator knob is in the full off position by turning the regulator control knob counterclockwise. SUDDEN PRESSURE EXERTED TO THE REGULATOR MAY CAUSE INTERNAL DAMAGE.

4. Slowly turn the tank valve fully open (counterclockwise). This will allow nitrogen to pressurize the regulator.

5. Insert the male Schrader end of the hose into the female Schrader on the regulator with an upward thrust. 6

6. Operating pressure is established by gradually turning the regulator control knob clockwise. ALWAYS establish the designated pressure on the operating pressure gauge with the instrument running.

Before removing the instrument from the regulator: 1. Close the tank valve by turning it clockwise. 2. Activate the instrument to bleed off line pressure. 3. Turn the pressure regulator knob counterclockwise until it stops. 4. Turn the female Schrader to the right to disengage the male Schrader fitting. 5. The hose can then be removed from the connector. Hold the end of the hose securely when disengaging the male Schrader fitting to prevent possible damage to the diffuser.

2.2 Equipment Installation and Operation Hose Installation 1. Place the handpiece in the “SAFE” position. 2. Slide the safety lock on the throttle lever toward the tip of the instrument. The word “SAFE” should be visible on the throttle lever.

7

3. On the Wiredriver 100 Handpiece, place the activation lever in the “SAFE” position.

To connect the handpiece to the hose: 1. Place the coupling end of the hose over the swivel fitting on the handpiece.

2. Push together and twist the hose coupling clockwise so the internal pins of the handpiece are secured in the indentations of the hose coupling.

3. The quick-disconnect coupling allows the handpiece to be removed from the hose for easy cleaning and/ or packaging for sterilization and service. 4. The automatic check valve in the end of the hose permits removal of the hose under pressure. After use, the hose should be removed from the regulator. Use care to prevent dirt or debris from entering the end of the handpiece when the handpiece and hose are separated. 8

5. After the appropriate guard, attachment, and/or bur or blade have been installed, the handpiece is ready for operation. To activate the handpiece: 1. Lift the throttle lever and slide the safety lock to the “ON” position.

2. Depress the throttle lever to activate the handpiece. 3. If using the Wiredriver 100 handpiece, place the Activation Lever in either the “FORWARD” or “REVERSE” position. 4. For the Wiredriver 100, depress the trigger. Foot Control Connection NOTE: The Foot Control does not operate with the Wiredriver 100 Handpiece (5053-013) To use the optional Foot Control (1375-028) attach accordingly: 1. Attach the Foot Control hose to the nitrogen regulator. 2. Insert the male end of the Universal Hose (5052-010) into the Foot Control.

3. Attach the Universal Hose to the handpiece (See “ Hose Installation” on page 7). 4. After the hose is connected, lift the throttle lever and slide the safety lock to the “ON” position.

9

5. Place the Throttle Clip (5053-074) over the handpiece throttle lever.

6. Depress the Foot Control pedal to activate the handpiece.

2.3 Micro 100 Drill (5053-009)

❶

❷

❸

❺

❻

❹

The Hall Micro 100 Drill may be used for cutting, sculpting, drilling, shaping bone, reaming the intramedullary canal of small bones, as well as wire passing. The Micro 100 Drill has a full range, variable speed control from 500 to 20,000 rpm and torque output of 6 in. oz. 1. Throttle Extension - Used to extend the gripping range of the throttle. Simply pull the extension outward. 2. Throttle Lever - Depress to activate the handpiece when the safety lock is in the “ON” position. 3. Safety Lock - Used to place the handpiece in the “ON” position or the safe mode. Slide the safety lock to the “SAFE” position when changing accessories. To activate the handpiece, slide the safety lock to the “ON” position. 4. Quick Disconnect Coupling - Used to quickly attach/detach the air hose to the handpiece. 10

5. 360° Swivel - Allows the handpiece to swivel independently for easy positioning of the handpiece in the surgical site. 6. Twist Bur Lock - Used to lock a bur into the handpiece. 2.3.1 Hall Bur Guard Assembly Instructions

!

WARNINGS: 1. Do not operate the drill without the appropriate bur guard. Always use a bur of the proper length. The tip of the bur guard should cover the safe line on the bur. Without the stabilization that the proper guard provides, the bur can break and be propelled with great force. 2. To reduce the risk of injury, prior to surgery, spin the bur guard on a bur. If the bur guard spins freely, the bearing is still good. Otherwise, the bur guard must be sent for repair immediately. DO NOT USE.

Table 1: Bur Guard and Attachment Guide REF

Description

Instructions

1375-011

Long Bur Guard - Use only 5092 series long burs

See page 12

1375-012

Medium Bur Guard - Use only 5091 series medium bur except 5091-080, 5091-081, 5091-082 and 5091-083

See page 12

1375-020

Laminectomy Bur Guard - Use only 5092-103 Long Carbide Bur

See page 12

1375-021

Rhinoplasty Bur Guard - Use only 5092-174 Rhinoplasty Bur.

See page 12

1375-023

Cloward Extra-Long Bur Guard - Use only 5093 series extra-long burs

See page 12

1375-032

20° Angle Attachment - Use only 5092 series long burs

See page 15

1375-033

20° XL Angle Attachment - Use only 5093 series extra-long burs

See page 15

1375-034

70° Contra-Angle Attachment with Dental Head - Use only 5089 extra-short burs and 5090 series short burs

See page 15

1375-035

70° Contra-Angle Attachment with Surgical Head - Use only 5089 extra-short burs and 5090 series short burs

See page 16

1375-036

90° Angle Attachment - Use only 5089 extra-short burs and 5090 series short burs

See page 16

1387-022

Tissue Retractor Guard - Use only with long burs (5092 series) which have a diameter of 4.0mm or less. Recommended bur: 5092-136

See page 12

11

2.3.2 Assembly Instructions - Bur Guards • Long Bur Guard (1375-011) • Medium Bur Guard (1375-012) • Tissue Retractor Guard (1375-022) • Cloward Extra-Long Bur Guard (1375-023) NOTE: When using the Tissue Retractor Guard, use only 5092 series long burs which have a diameter of 4.0 mm or less. The recommended bur is the 5092-136 Long Oval Cutting Bur. 1. Place the handpiece in the “SAFE” position.

To install a bur guard: 1. Slide the appropriate bur guard over the end of the drill. Ensure it is seated completely. Do not operate the drill without the bur guard completely seated to the nose of the drill.

Photo below shows the Tissue Retractor Guard.

To install a bur: 1. Select a proper length bur for the guard. 2. Twist the bur lock counterclockwise to the unlocked position.

12

3. Insert the bur to the safe line or until the bur seats completely.

4. Lock the bur in place by twisting the bur lock clockwise until the red indicator dots are aligned. PRECAUTION: Never lock the collet without a bur inserted. Damage to the collet may result.

2.3.3 Assembly Instructions - Laminectomy & Rhinoplasty • Laminectomy Bur Guard (1375-020) • Rhinoplasty Bur Guard (1375-021 NOTES: •

Use the 5092-103 Long Carbide Bur with the 1375-020 Laminectomy Bur Guard. Use the 5092-174 Rhinoplasty Bur with the 1375-021 Rhinoplasty Bur Guard.

•

The Laminectomy and Rhinoplasty burs are the only burs that can be inserted prior to placing the appropriate bur guard on the handpiece.

1. Place the handpiece in the “SAFE” position.

13

To install a bur: 1. Twist the bur lock counterclockwise to the unlocked position.

2. Insert the laminectomy or rhinoplasty bur into the handpiece until the bur seats completely.

3. Lock the bur in place by twisting the bur lock clockwise until the red indicator dots are aligned. PRECAUTION: Never lock the collet without a bur inserted. Damage to the collet may result.

14

To install a bur guard: 1. Slide the appropriate bur guard over the bur and the end of the handpiece. Ensure it is seated completely. Do not operate the drill without a bur guard completely seated to the nose of the drill.

2.3.4 Assembly Instructions - Angle Attachments • 20° (1375-032) • 20° Extra Long (1375-033) NOTE: Use only long burs (5092 series) in the 1375-032, 20° Angle Attachment and extra long burs (5093 series) in the 1375-033, 20° Extra Long Angle Attachment. 1. Place the handpiece in the “SAFE” position.

To install the attachment: 1. Twist the bur lock counterclockwise to the unlocked position.

2. Slide the attachment over the end of the drill. Ensure it is seated completely.

15

3. Lock the attachment in place by twisting the bur lock clockwise until the red indicator dots are aligned.

4. Open the attachment collet by twisting the attachment bur locking ring counter-clockwise until the ring is fully open. 5. Insert the bur into the attachment until it is completely seated.

6. Twist the attachment bur locking ring clockwise until the locking ring is in the locked position. 2.3.5 Assembly Instructions - Contra-Angle Attachments • 70° Contra-Angle with Surgical Head (1375-034) • 70° Contra-Angle with Dental Head (1375-035) • 90° Contra-Angle with Angle (1375-036) NOTE: Use only short burs (5090 series) and extra short burs (5089 series) with these attachments. 1. Place the handpiece in the “SAFE” position.

16