1 Page

Preview

Page 1

IFU-033 rev B JUN 2016 INSTRUCTIONS FOR USE

CATH HIP INSTRUMENTATION OMNIlife science, Inc. 480 Paramount Drive Raynham, MA 02767 USA www.omnils.com (508) 824-2444

Stop Instrument, Disassembl y for Precleaning, Cleaning, and Sterilization

LABEL SYMBOLS See Instructions for Use Rx only QTY

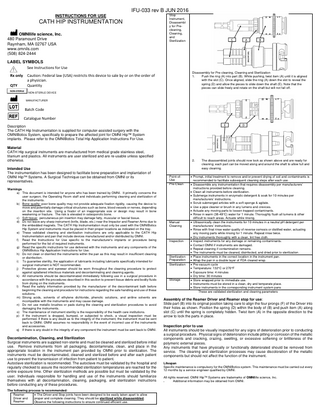

Disassembly for Pre-cleaning, Cleaning and Sterilization 1. Push the ring (A) into part (B). While pushing, twist item (A) until it is aligned with the slot (C). Once aligned, slide the ring (A) down the slot to reveal the spring (D) and allow the pieces to slide down the shaft (E). Note that the pieces can slide freely and rotate on the shaft but will not fall off.

Caution: Federal law (USA) restricts this device to sale by or on the order of a physician. Quantity NON-STERILE DEVICE MANUFACTURER

Batch Code Catalogue Number Description The CATH Hip Instrumentation is supplied for computer-assisted surgery with the OMNIBotics System, specifically to prepare the affected joint for OMNI Hip™ System implants. Please refer to the OMNIBotics Total Hip Application Instructions For Use. Material CATH Hip surgical instruments are manufactured from medical grade stainless steel, titanium and plastics. All instruments are user sterilized and are re-usable unless specified otherwise. Intended Use The instrumentation has been designed to facilitate bone preparation and implantation of OMNI Hip™ Systems. A Surgical Technique can be obtained from OMNI or its representatives. Warnings a) This document is intended for anyone who has been trained by OMNI. It primarily concerns the user surgeon, the Operating Room staff and individuals performing cleaning and sterilization of the instruments. b) Bone quality: poor bone quality may not provide adequate fixation rigidity, causing the device to move and potentially damage critical structures such as bone, blood vessels or nerves, depending on the insertion site. Using a fixator of an inappropriate size or design may result in bone weakening or fracture. The risk is elevated in osteoporotic bone. c) Soft tissue: percutaneous pin insertion may damage fatty, muscular or fascial tissue. d) Do not leave any sharp instrument (knife, blade, etc.) near the Impactor and Reamer Arms due to the embedded magnets. The CATH Hip Instrumentation must only be used with the OMNIBotics Hip System and instruments must be placed in their proper locations as indicated on the tray. e) These validated cleaning and sterilization instructions are only applicable to the CATH Hip Instrumentation and pan that include devices manufactured and/or distributed by OMNI. f) Read the Instructions for Use specific to the manufacturer's implants or procedure being performed for the list of required instruments. g) Read the specific instructions for use delivered with the instruments and any components of the OMNIBotics Hip Application Instructions for Use. h) Do not clean or disinfect the instruments within the pan as this may result in insufficient cleaning or disinfection. i) To guarantee sterility, the application of lubricants including lubricants specifically intended for surgical instrument is NOT recommended. j) Protective gloves and eyewear should be worn throughout the cleaning procedure to protect against splattered infectious materials and decontaminating and cleaning agents. k) All instruments should be decontaminated immediately following use in a surgical procedure in accordance with the procedures described in this section to prevent tissue debris and bodily fluids from drying on the instruments. l) Read the safety information provided by the manufacturer of the decontaminant bath before beginning the cleaning and procedure for instructions regarding the safe handling and use of these solutions. m) Strong acids, solvents of ethylene dichloride, phenolic solutions, and aniline solvents are incompatible with the instruments and may cause damage. n) Do not use metallic brushes or pads during the cleaning and sterilization procedures to avoid damaging the instruments. o) The maintenance of instrument sterility is the responsibility of the health care institutions. p) If the instrument is dropped, bumped, or subjected to shock, a visual inspection must be performed. If there is any doubt as to the integrity of the instrument, the instrument must be sent back to OMNI. OMNI assumes no responsibility in the event of incorrect use of the instruments and accessories. q) If there is any doubt in the integrity of any component the instrument must be sent back to OMNI.

Decontamination, Cleaning, and Sterilization Surgical instruments are supplied non-sterile and must be cleaned and sterilized before initial use. Remove instruments from all packaging, decontaminate, clean, and place in the appropriate location in the instrument pan provided by OMNI prior to sterilization. The instruments must be decontaminated, cleaned and sterilized before and after each patient use to prevent the transmission of infection from patient to patient. Autoclave sterilization is recommended. The autoclave must be validated by the hospital and regularly checked to assure the recommended sterilization temperatures are reached for the entire exposure time. Other sterilization methods are possible but must be validated by the user. Individuals responsible for handling and use of the instruments should familiarize themselves with all decontamination, cleaning, packaging, and sterilization instructions before conducting any of these procedures. The following process is recommended: Reamer The Driver and Stop joints have been designed to be easily taken apart to allow Driver and proper and complete cleaning. They should be sterilized while disassembled. Reamer Observe the following instructions to ensure continued efficient use.

2.

Point-ofUse Pre-Clean

Manual Cleaning

Inspection

Sterilization Preparation Sterilization

Storage

The disassembled joints should now look as shown above and are ready for cleaning; each part can be moved along and around the shaft to allow full and easy cleaning.

Prompt, initial treatment to remove and/or prevent drying of soil and contaminants is recommended to facilitate subsequent cleaning steps after each use. Disassemble any instrumentation that requires disassembly per manufacturers’ instructions provided before cleaning. Clean all instruments before sterilization. Submerge instruments in enzymatic detergent & soak for 10 minutes per manufacturers’ instructions. Scrub submerged articles with a soft sponge & agitate. Use a pipe cleaner or brush in any lumens and crevices. Actuate any moving parts to loosen trapped contaminants. Rinse in warm (38-49C) water for 1 minute. Thoroughly flush all lumens & other difficult to reach areas. Actuate while rinsing. Ultrasonically clean the instruments for 10 minutes in a neutral pH detergent per manufacturers’ instructions. Rinse with final rinse water quality of reverse osmosis or distilled water, actuating any moving parts while rinsing for 1 minute. Repeat rinse twice. Dry instruments thoroughly with a clean, lint free cloth. Inspect instruments for any damage or remaining contaminants. Contact OMNI if instruments are damaged. Repeat cleaning if contamination remains. The instruments must be cleaned, disinfected, and dried prior to sterilization. Place instruments in the correct location in the instrument pan. Wrap the pan in a double layer of FDA cleared wrap. Pre-vacuum cycle Temperature: 132°C or 270°F Exposure time: 4 minutes Dry time: 30 minutes Store wrapped prior to immediate use. Instruments must be stored in a clean, dry and temperate place. Store instruments in the corresponding instrument system pans. These are validated sterilization and cleaning parameters

Assembly of the Reamer Driver and Reamer stop for use: Slide part (B) into its original position taking care to align the four prongs (F) of the Driver into their holes as shown. Position the spring (D) within the body of (B) and push item (A) along slot (C) until the spring is completely hidden. Twist item (A) in the opposite direction to the arrow to lock the parts in place. Inspection prior to use All instruments should be visually inspected for any signs of deterioration prior to conducting a surgical procedure. Physical signs of deterioration include pitting or corrosion of the metallic components and cracking, crazing, swelling, or excessive softening or brittleness of the polymeric external pieces. Any instruments that have physically or functionally deteriorated should be removed from service. The cleaning and sterilization processes may cause discoloration of the metallic components but should not affect the function of the instrument. Lifespan Specific maintenance is compulsory for the OMNIBotics system. This maintenance must be carried out every 12 months by a service engineer qualified by OMNI. All rights reserved. OMNI Hip™ Systems are trademarks of OMNIlife science, Inc. Additional information may be obtained from OMNI.