CORIN

AK3 Congruent Insert Trial Size 2, 11mm

APEX Knee and OMNIHip System Instrumentation Instructions for Use

2 Pages

Preview

Page 1

IFU-011 rev I MAY2019 OMNIlife science, Inc. 480 Paramount Dr. Raynham, MA 02767 USA www.omnils.com (508)824-2444 Rx: Federal law (USA) restricts this device to sale or use by or on the order of a physician. APEX Knee™ System devices conform to

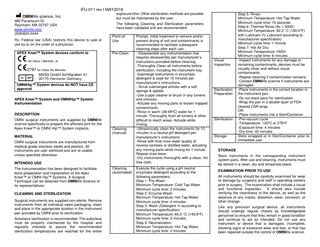

exposure time. Other sterilization methods are possible but must be maintained by the user. The following Cleaning and Sterilization parameters have been validated and are recommended: Point-ofUse

Pre-Clean

for class I devices or

2797 for class IIa devices MDSS GmbH Schiffgraben 41 30175 Hannover Germany OMNIHip™ System devices do NOT have CE approval APEX Knee™ System and OMNIHip™ System Instrumentation DESCRIPTION OMNI surgical instruments are supplied by OMNIlife science specifically to prepare the affected joint for the Apex Knee™ or OMNI Hip™ System implants.

Cleaning (manual)

MATERIAL OMNI surgical instruments are manufactured from medical grade stainless steels and plastics. All instruments are user sterilized and are re-usable unless specified otherwise. INTENDED USE The instrumentation has been designed to facilitate bone preparation and implantation of the Apex Knee™ or OMNI Hip™ Systems. A Surgical Technique can be obtained from OMNIlife Science or its representatives. CLEANING AND STERILIZATION Surgical instruments are supplied non-sterile. Remove instruments from all individual sales packaging, clean and place in the appropriate location in the instrument pan provided by OMNI prior to sterilization. Autoclave sterilization is recommended. The autoclave must be properly maintained by the hospital and regularly checked to assure the recommended sterilization temperatures are reached for the entire

Cleaning (automated)

Prompt, initial treatment to remove and/or prevent drying of soil and contaminants is recommended to facilitate subsequent cleaning steps after each use. - Disassemble any instrumentation that requires disassembly per manufacturer’s instructions provided before cleaning. -Thoroughly Clean all instruments before sterilization, including the instrument tray. -Submerge instruments in enzymatic detergent & soak for 10 minutes per manufacturer’s instructions. - Scrub submerged articles with a soft sponge & agitate. -Use a pipe cleaner or brush in any lumens and crevices. -Actuate any moving parts to loosen trapped contaminants. -Rinse in warm (38-49oC) water for 1 minute. Thoroughly flush all lumens & other difficult to reach areas. Actuate while rinsing. -Ultrasonically clean the instruments for 10 minutes in a neutral pH detergent per manufacturer’s instructions. -Rinse with final rinse water quality of reverse osmosis or distilled water, actuating any moving parts while rinsing for 1 minute. Repeat rinse twice. -Dry instruments thoroughly with a clean, lint free cloth. Execute the cycle using a pH neutral enzymatic detergent according to the following parameters: Step 1: Pre-Wash: Minimum Temperature: Cold Tap Water Minimum cycle time: 2 minutes Step 2: Enzyme Wash: Minimum Temperature: Hot Tap Water Minimum cycle time: 4 minutes Step 3: Wash (Detergent % according to manufacturer specification): Minimum Temperature: 65.5 °C (149.9°F) Minimum cycle time: 2 minutes Step 4: Neutralization: Minimum Temperature: Hot Tap Water Minimum cycle time: 2 minutes

Visual Inspection

Sterilization Preparation

Sterilization

Storage

Step 5: Rinse: Minimum Temperature: Hot Tap Water Minimum cycle time: 15 seconds Step 6: Thermal Rinse (A0 = 3000): Minimum Temperature: 82.2 °C (180.0°F) with Lubricant (% Lubricant according to manufacturer specification) Minimum cycle time: 1 minute Step 7: Hot Air Dry: Minimum Temperature: HIGH Minimum cycle time: 6 minutes -Inspect instruments for any damage or remaining contaminants, devices must be visually clean and without visual contaminants. -Repeat cleaning if contamination remains. -Contact OMNIlife science if instruments are damaged. -Place instruments in the correct location in the instrument pan. -Do not stack pans for sterilization -Wrap the pan in a double layer of FDA cleared CSR wrap. OR -Place instruments into a SterilContainer -Pre-vacuum cycle -Temperature: 132oC or 270oF -Exposure time: 4 minutes -Dry time: 40 minutes Store wrapped or in SterilContainer prior to immediate use.

STORAGE Store instruments in the corresponding instrument system pans. After use and cleaning, instruments must be stored in a clean, dry and temperate place. EXAMINATION PRIOR TO USE All instruments should be carefully examined for wear or damage by surgeons and staff in operating centers prior to surgery. The examination shall include a visual and functional inspection. It should also include verifying the cleanliness of the device, as well as the absence of any cracks, distortion, wear, corrosion, or other change. Like any precision surgical device, all instruments should undergo regular checks by knowledgeable personnel to ensure that they remain in good condition and continue to act as intended. Do not use any instrument or device that is damaged, incomplete, showing signs of excessive wear and tear, or that has been repaired outside the control of OMNIlife science.

IFU-011 rev I MAY2019 WARNINGS AND PRECAUTIONS OMNIlife science devices must only be used by surgeons who have been trained in the surgical technique and are familiar with the instruments provided. The surgeon must take care not to exert inappropriate stress on the device and must comply with the operating procedure described in the surgical technique. Prior to using the instrument system, the surgeon should give careful consideration to all aspects of the surgical intervention as well as the limitations of the implant and instruments. Use care in handling and storage. Some instruments are sharp and incorrect use or handling may result in puncture wounds. Do not use devices with drills that exceed 1500 rpm. Improper use may result in breakage of the instrumentation during operation. Remove all broken instrument fragments. As a result of mechanical features required, the device is made of medical grade but not implant grade materials. Failure to remove broken instruments from the patient could result in patient complications and further intervention. Incorrect maintenance, cleaning or handling may render the instrument unsuitable for its intended use, cause corrosion, dismantling, distortion and/or instrument breakage or injury to the patient or operating staff. Potential complications include device breakage, leaching of debris, lack of component engagement, infection, and damage to tissue. All rights reserved. Apex Knee™ System and OMNIHip™ System are trademarks of OMNIlife science, Inc. Additional information may be obtained from OMNIlife science, Inc.