Operating Instructions

74 Pages

Preview

Page 1

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

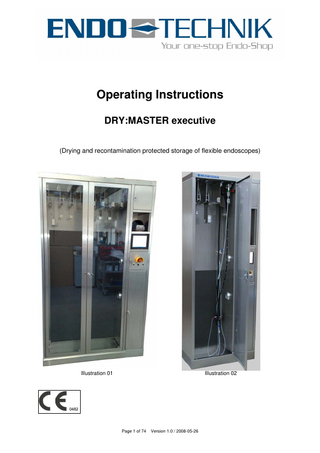

Operating Instructions DRY:MASTER executive (Drying and recontamination protected storage of flexible endoscopes)

Illustration 01

Illustration 02

Page 1 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

Note In case of an occuring problem with DRY:MASTER switch off the EMERGENCY-STOP button and unplug the power-plug before carrying out any work at the DRY:MASTER. Please read instructions carefully before operating or using this device.

Warning The operator is responsible for the regular inspection of the technical safety and ability to work of this device.

Producer:

WG ENDO-TECHNIK GmbH Heiligenstock 32 42697 Solingen Germany Tel.: +49 (0)212 / 267 43-0 Fax: +49 (0)212 / 267 43-50 E-Mail: [email protected]

Page 2 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

Content: 1. Safety Notes 2. Purpose / General Function 3. Initial Commissioning 4. Operation 5. Servicing an Maintenance 6. Troubleshooting 7. Technical Data Appendix I: Appendix II: Appendix III: Appendix IV: Attachments:

Connection of Endoscopes Equipment Spare Parts Register of Illustrations Declaration of Conformity DIN EN ISO 13485:2001 Certificate EC Certificate of Conformity according to RL 93/42/EWG, Addendum II

Important Notes for Use Reading the operating instructions Read these operating instructions before the initial use of your DRY:MASTER and get to know the operation and functionality of this device and its equipment. If you do not follow these instructions this can cause serious injury to the patients, users and service staff or damage resp. complete failure of the device. Account book We recomment to keep an account book of the device with the following content: - operting instructions - declaration of conformity (see attachment) - briefing and handing-over records - service records Technical alterations ENDO-TECHNIK W. Griesat GmbH indicates that product alterations due to technical advances are subject to change, also without prior notice. Therefore illustrations and descriptions in this handbook can differ from the delivered product. Equipment For using the DRY:MASTER according to its purpose certain equipment is essential which is described in these operating instructions.

Page 3 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

Directions Please pay special attention to the directions marked with symbol

:

Danger Direction to avoid injury of a patient, user, service staff or another person. Warning Direction to ensure the appropriate use of the device and its equipment. Note Special directions and advices for handling, installation and maintenance of the device and its equipment.

1. Safety Notes Liability terms Exclusion of liability: ENDO-TECHNIK W. Griesat GmbH assumes no liability for damages or consequential losses when: − the device and its equipment were used, worked on or maintained incorrectly. − advices or regulations of these instructions for use are disregarded. − persons who are not authorized repair, make adjustments or alterations of the device or the equipment. − persons who are not authorized open the device. − the prescribed intervals for inspection and maintenance are not kept.

Authorized service engineer Warning Only by ENDO-TECHNIK W. Griesat GmbH authorized service engineers may repair, take adjustments or alterations of the device and equipment. The authorization and registration as authorized service engineer exclusively follows after adequate instruction/training by ENDO-TECHNIK.

Page 4 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

Intended use Warning The DRY:MASTER must only be used according to its purpose in the way which is described in these operating instructions. Special conditions Note Before initial use of the DRY:MASTER make sure that in the preparation or keeping room there is enough space on the clean side for installing the device and that there is the necessary connection to the supply system. Installation Note When installing pay attention to the standard DIN/VDE 0750 part 1 resp. IEC 601-1 passage 19. Introduction Note The introduction on site is carried out by the company ENDO-TECHNIK W. Griesat GmbH or by a medical product adviser who was authorized by us. Servicing and maintenance Warning The here described advices for servicing and maintenance of the DRY:MASTER have to be kept absolutely to ensure a secure running. Functional test Warning Check the completeness and the perfect function of DRY:MASTER before resp. while using. Make sure the device is properly installed before initial use and after repair.

Page 5 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

Dangers (general) ¾ Unauthorized opening of the device When opening the control unit of the device there is the danger of touching live parts, therefore an electric shock. Never open the control unit yourself for this reason. The control unit must only be opended by a service engineer who is authorized by ENDO-TECHNIK W. Griesat GmbH. ¾ Infiltration of liquids Liquids which infiltrated the control unit can lead to dysfunction and/or the danger of an electric shock. Therefore liquids must not get into the control unit. Always keep away liquids from this electric part. Never use the device when liquids infiltrated the control unit. ¾ Running in explosion-proof areas The device is not explosion-proof. Operation in areas with explosive gases can lead to great damages and injury. ¾ Use of incompatible equipment The use of incompatible equipment can lead to dysfunction with the danger of injury to patients, users or service engineers. Therefore only use equipment which is DRY:MASTER specified. ¾ Damaged hardware protection When replacing a damaged hardware protection make sure the new protection corresponds to the data on the device, resp. these operating instructions. The use of a wrong protection can lead to dysfunction with injury to users or other persons. ¾ Device failure The use of damaged devices is dangerous in general. Do not use the device when it is assumedly or evidently faulty. Secure the device against further use until it was inspected by an authorized service engineer. Further device specific safety notes you will find in the particular chapters of these operating instructions.

Page 6 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

2. Purpose / General Function The DRY:MASTER is a compartment drier for complete drying and recontaminationprotected, dust-free, vertically hung up storage of cleaned and sterilized flexible endoscopes. Note The DRY:MASTER must only be used for the storage of cleaned and sterilized flexible endoscopes. Make sure that no unclean or not sufficiently sterilized endoscopes are hung up in the compartment drier. Note The DRY:MASTER must only be used for the storage of cleaned and sterilized flexible endoscopes. It is unsuitable for storage of instruments or other equipment which is used during endoscopy.

Contraindications: Never use the DRY:MASTER for the storage of unclean or not sufficiently sterilized endoscopes or for other endoscopic instruments.

Page 7 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

Page 8 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

3. Initial Commissioning Incoming inspection Check the device and the supplied equipment immediately after receipt if it is complete and if there are any externally visible damages. The usual extent of delivery includes (variations can occur because of individual orders): -

DRY:MASTER 8x connecting tubes (for DRY:MASTER with 4 channels: 4x connecting tubes) 8x sterilized gas filters (for DRY:MASTER with 4 channels: 4x sterilized gas filters) cold-device power cable with three-pin plug operating instructions printer (only for advanced and executive version) 5x label continuous-roll (300 pieces) for printer (only for Advanced / Executive Version)

Return of the device Note If a device return should be necessary, please use the original packing. No liability is assumed for transport damages caused by inadequate packing.

Page 9 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

Installation of DRY:MASTER General view of the device

①

②

⑥ ③

④

⑤

Illustration 03 front view closed

① Main chamber:

endoscope keeping chamber

② Valves/ tubing:

④ EMERGENCY-STOP:

touchscreen with display- and controlpanel touchscreen with display- and controlpanel (optionally available as ECO version with key-control) emergency stop switch

⑤ Compressor chamber:

chamber for compressor

⑥ Printer:

thermo printer (for the listing)

③ Control panel:

Page 10 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

⑤

⑤ ⑦

⑥

①

Illustration 04 endoscope chamber

① Main chamber:

endoscope keeping chamber

⑤ Holder:

extendable endoscope holders

⑥ Tubes:

connecting tubes with filter

⑦ Drying channels:

Luer-Lock connections for connecting tubes

Page 11 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

⑦

⑦

Illustration 05 drying channels

⑦ Drying channels: Luer-Lock connections for connecting tubes

Illustration 06 main page

Page 12 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

Illustration 07 – run time display

The DRY:MASTER executive is managed by the control panel. Service technicians and trained persons are setting up the DRY:MASTER executive by this control panel. In process the user normally uses only the two pages “Main Page” (Ill 06) and “Run Time Display” (Ill 07).

Page 13 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

Placement of the device Choose a dry area as running location for DRY:MASTER with a relative humidity of max. 70% and with a room temperature between 10°C and 35°C. The cabinet should stand on a solid plane surface and should be located on the clean side of the preparation resp. storage room. It is recommended to place the device against a wall. These instructions should be kept in an unhidden accessible place. Power supply The DRY:MASTER is connected to the power supply system via the “cold-device cable“ which is also delivered ⑰.

⑱

Illustration 08 side view

⑰

⑲

Illustration 09 top view

⑰ Mains connection:

connection for mains cable (~220 Volt)

⑱ Ventilation:

ventilation louvres

⑲ Network (LAN):

LAN (10MBit / 100 MBit) connector Page 14 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

③ ④

⑳ Illustration 10 control panel executive version

¾

¾ ¾

④ EMERGENCY-STOP:

emergency stop switch

③ Touch-Sreen: / Control Panel

All controls and setups are managed by the touchscreen

⑳ Key:

key (for opening the drawer for service reasons)

Warning Make sure, that the provided supply voltage corresponds with the supply voltage which is declared on the device type sign (position: at the top of right door inside). The wrong voltage can lead to dysfunction and damage of the device. Danger The mains connection has to have an earthing contact. The device is not explosion-proof. Never run the device in a location with possible explosive gases.

After installing the DRY:MASTER properly it is ready for use. The described processes below have to be carried out during initial commissioning and also for the regular operation.

Page 15 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

Suspension check, remove transport protection •

When delivered there is always a transport protection fastened to the suspensions.

•

Please take off this transport protection and check if the suspension can be moved in and out without problems.

Illustration 11

Page 16 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

4. Operation of the DRY:MASTER Initial commissioning and device checkup •

Check the correct connection to the power supply.

•

Switch on the DRY:MASTER with the power switch. (this switch contains two main fuses for the DRY:MASTER executive)

Illustration 12

•

Switch on the internal Power Switch for the embedded PC and internal USV accumulator.

Note When the DRY:MASTER executive is beeing delivered this switch is in position „OFF“. So the embedded PC and control panel will not start if the main switch is switched on. In normal condition this switch will be left in “ON” position.

Note Switch “OFF” this Power Switch for the embedded PC only if the DRY:MASTER will be switched of for a longer time period. With this power connection also the USV accumulator will be loaded that gives power to the embedded PC and control panel in case of complete power loss for approx. 3h.

Note If a complete power loss will be longer as 3h please shut down the embedded pc manually by log of and shut down the Windows XP. Illustration 13 Page 17 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

•

In the standby mode the DRY:MASTER Advanced shows the main page 1 on the control panel.

Illustration 14

•

Carry the endoscope after cleaning and sterilizing according to the hygienic regulations in a closed transport container to the DRY:MASTER.

Illustration 15

•

Open the main chamber ① and pull the fitting endoscope holder ⑤ forwardly out of the main chamber.

Illustration 16

¾

Note The DRY:MASTER can have different endoscope holders depending on the configuration. Make sure to use the right holder for the actual endoscope.

Page 18 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

Illustration 17a Fuji / Olympus endoscope holder

¾

Illustration 17b Pentax endoscope holder

Warning Never put the endoscopes in holders which are intended for other endoscope versions. This could lead to damage to the endoscope. •

Take the endoscope off the container according to the hygienic regulations and put it in the provided extendable endoscope holder of the DRY:MASTER.

•

Connect the connecting tube with the filter ending to one of the eight drying channels ⑦.

Illustration 18

Illustration 19

Page 19 of 74

Version 1.0 / 2008-05-26

WG ENDO-TECHNIK W.Griesat GmbH • Heiligenstock 32 • 42697 Solingen « 0212-26743-0 ¬ 0212-2674350

•

•

Connect the four tube endings to the corresponding channel of the endoscope. Take account of the directions for use of the endoscope maker. Pay attention to the following colour codes: Blue: air/ rinse channel Red: exhaust channel Green: biopsy channel White: jet channel Unused tube endings have to be closed with a sealing cap. Illustration 20

• •

Push the endoscope holder with the tubed endoscope into the main chamber again. Make sure the tubes hang without folds and do not touch each other or the bottom of the cabinet.

Illustration 21

•

Activate the drying channel which is connected to the endoscope in the following way:

Illustration 22

Page 20 of 74

Version 1.0 / 2008-05-26