32 Pages

Preview

Page 1

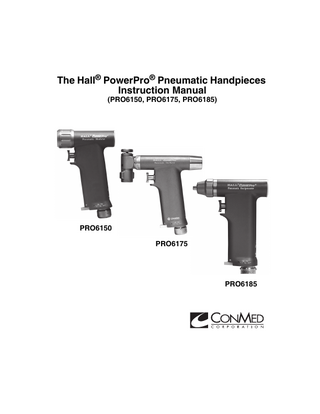

The Hall® PowerPro® Pneumatic Handpieces Instruction Manual (PRO6150, PRO6175, PRO6185)

PRO6150 PRO6175

PRO6185

Proprietary Information This manual contains information deemed proprietary to Linvatec Corporation. The information contained herein, including all of the designs and related materials, is the sole property of ConMed Linvatec and/or its licensors. ConMed Linvatec and/or its licensors reserve all patent, copyright and other proprietary rights to this document, including all design, manufacturing methodology and reproduction. This document, and any related materials, is confidential and is protected by copyright laws and shall not be duplicated, transmitted, transcribed, stored in a retrieval system, or translated into any human or computer language in any form or by any means, electronic, mechanical, magnetic, manual or otherwise, or disclosed to third parties, in whole or in part, without the prior express written consent of ConMed Linvatec. ConMed Linvatec reserves the right to revise this publication and to make changes from time to time in the contents hereof without obligation to notify any person of such revision or changes, unless otherwise required by law.

Linvatec, Hall, and PowerPro, are trademarks or registered trademarks of Linvatec Corporation.

Linvatec Corporation 2012, 2014. All Rights Reserved.

Record the Model and Serial Numbers of the handpiece(s), and date received. Retain for future reference. Handpiece Model No.

Serial No

Date

Handpiece Model No.

Serial No

Date

Handpiece Model No.

Serial No

Date

Handpiece Model No.

Serial No

Date

Handpiece Model No.

Serial No

Date

Handpiece Model No.

Serial No

Date

Table of Contents

1.0

2.0

3.0

Page

INTRODUCTION 1.1

Intended Use... 1

1.2

Operating Principle... 1

1.3

Environmental Directives... 1

1.4

Warnings and Precautions... 2 1.4.1

Warnings... 2

1.4.2

Precautions... 3

1.5

Symbol Definitions... 4

1.6

PowerPro® Pneumatic Modular Handpiece (PRO6150)... 5

1.7

PowerPro® Pneumatic Oscillator Handpiece (PRO6175)... 6

1.8

PowerPro® Pneumatic Reciprocator Handpiece (PRO6185)... 7

INSTALLATION AND OPERATION 2.1

Power Source and Regulator Installation and Operation... 8

2.2

Connecting and Removing Attachments... 12

2.3

Handpiece Mode Selection and Operation... 12 2.3.1

PowerPro® Pneumatic Modular Handpiece (PRO6150)... 12

2.3.2

PowerPro® Pneumatic Oscillator Handpiece (PRO6175)... 13

2.3.3

PowerPro® Pneumatic Reciprocator Handpiece (PRO6185)... 15

MAINTENANCE 3.1

Cleaning and Sterilization... 17 3.1.1

3.2

Cleaning Precautions... 17

Handpiece Cleaning Instructions... 18 3.2.1

Sterilization Information Warnings, Precautions and Notes... 18

3.2.2

Troubleshooting... 21

i

Table of Contents

4.0

5.0

Page

TECHNICAL SPECIFICATIONS 4.1

Handpiece Environmental Requirements... 22

4.2

PowerPro® Pneumatic Modular Handpiece (PRO6150)... 22

4.3

PowerPro® Pneumatic Oscillator Handpiece (PRO6175)... 23

4.4

PowerPro® Pneumatic Reciprocator Handpiece (PRO6185)... 23

4.5

Handpieces, Attachments and Accessories... 24

CUSTOMER SERVICE 5.1

Assistance and Repair... 26

ii

1.0

INTRODUCTION

It is recommended that personnel study this manual before attempting to operate, clean, or sterilize PowerPro® Pneumatic Handpieces (PRO6150, PRO6175, PRO6185). The safe and effective use of this equipment requires the understanding of and compliance with all warnings, cautionary notices, and instructions marked on the product, and included in this manual.

1.1 Intended Use The PowerPro Pneumatic Modular Handpiece, along with an assortment of modular attachments, is designed to perform bone cutting, reaming, drilling, driving screws, sawing, and pin driving functions common to small and large bone orthopedic surgical procedures. This handpiece uses the same attachments as the PowerPro Electric and Battery Systems handpieces. The PowerPro Pneumatic Oscillator Handpiece is designed for sawing in small, large and transverse or longitudinal bone osteotomies, removal of the femoral head and neck, removal of the greater trochanter, resurfacing the tibial plateau and the distal end of the femur such as required in total knee or total hip arthroplasties. The PowerPro Pneumatic Reciprocator Handpiece is designed for sawing in large bone total joint arthroplasties. The fields of application for these handpieces include: Osteotomy, Trauma, Orthopedic and Total Joint Arthroplasty.

1.2 Operating Principle The PowerPro Pneumatic Handpiece is powered by a source of compressed dry nitrogen to provide a pneumatic application of mechanical force, rotary or reciprocal depending on the handpiece, to attachments and various accessories for bone cutting, reaming, drilling, driving screws, sawing, and pin driving functions used in large and/or small bone surgical procedures or arthropasties. The PowerPro Pneumatic Handpiece is controlled by an activation trigger and safety/direction lever on the handpiece.

1.3 Environmental Directives WEEE Directive [2002/96/EC] on Waste Electrical and Electronic Equipment. This statement only applies to European countries with regard to the Waste Electrical and Electric Equipment (WEEE) European Directive. The WEEE symbol on the product or its packaging indicates that this product must not be disposed of with other waste. Instead, it is your responsibility to dispose of your waste equipment by handing it over to a designated collection point for the recycling of Waste Electrical and Electronic Equipment. The separate collection and recycling of your waste equipment at the time of disposal will help conserve natural resources and ensure that it is recycled in a manner that protects human health and the environment. For more information about where you can drop off your medical equipment at the end of its useful life for recycling, please contact ConMed Linvatec. 1

1.4 Warnings and Precautions The words WARNING, PRECAUTION, and NOTE carry special meanings and they should be read carefully. WARNING: The safety and/or health of the patient, user, or a third party is at risk. Comply with this warning to avoid injury to the patient, user, or third party. PRECAUTION: This contains information concerning the intended use of the device or accessory. Damage to the equipment is possible if these instructions are not followed. NOTE: A note is added to provide additional, focused, information.

! ! !

This equipment is designed for use by medical professionals completely familiar with the required techniques and instructions for use of the equipment. Read and follow all warning and cautionary notices and instructions marked on the product and included in this manual. Prior to using the device, read and follow all warning and precautionary notices and instructions marked on the product and included in this manual. 1.4.1 Warnings

!

1.

Eye protection is always necessary when operating equipment. Eye injury may result.

2.

Do not attach, insert or remove accessories or attachments while the handpiece is operating. Place the handpiece in the “safe” position, if applicable, prior to installation or removal of items. Accidental activation of the handpiece could cause injury.

3.

Do not bind drill bit or reamer during use. Over exertion may cause patient injury, user injury, and/or damage to the instrument.

4.

Always inspect for bent, dull or damaged blades or drill bits before each use. Do not attempt to straighten or sharpen. Do not use if damaged. After use, dispose of properly.

5.

The instruments are supplied non-sterile, and must be sterilized before the first use, and after every use.

2

1.4.2 Precautions

!

1.

Handpieces are factory sealed. Do not disassemble or lubricate, as this may void your warranty. There are no user-serviceable parts inside.

2.

Use only associated Hall® Surgical and ConMed Linvatec accessories (saw blades, bits, etc.).

3.

Handle all equipment carefully. If the handpiece is dropped or damaged in any way, return it immediately for service.

4.

Never operate the handpiece above 110 psi (7.7 kg/cm2) dynamic pressure unless an extension hose is added to the standard 10 foot hose. Excessive pressure may cause damage to instrument and exert unusual stress on the hose.

5.

Continually check handpiece and attachments for overheating. If overheating is noticed, discontinue use and return equipment for service.

6.

Do not pressurize hoses until all fittings have been connected and checked.

7.

The nitrogen regulator is for use with pneumatically powered surgical devices only.

8.

Prior to each use, perform the following:

9.

•

Inspect all equipment for proper operation.

•

Ensure all attachments, accessories and hoses are correctly and completely attached to the handpiece.

•

Always inspect hoses for signs of wear or damage. Do not use worn or damaged hoses. Replace immediately.

•

Check all equipment for any air or nitrogen leakage. If leakage is noticed, return for service.

Do not handle the handpiece by the cord. Do not pull on the cord to remove it from the handpiece or controller.

10. Do not excessively bend or kink the handpiece cord. Always inspect cord for signs of excessive wear or damage. If wear or damage is found, discontinue use and replace immediately. 11. Do not operate the oscillating saw or reciprocator handpiece without a blade locked securely in place. Damage to the handpiece will occur. 12. Do not immerse handpieces in fluids.

3

1.5 Symbol Definitions

!

Attention, consult accompanying documents. Single Use Only. No user service recommended. Refer servicing to qualified ConMed Linvatec service personnel. Indicates handpiece should not be immersed in any fluid. Indicates product should not be oiled or lubricated. Eye Protection Required. Caution: Federal Law restricts this device to sale by or on the order of a physician.

R

S F

Indicates the “reverse” position for the PRO6150 Modular Handpiece or the “run” position for the PRO6175 Oscillator and PRO6185 Reciprocator Handpieces. Indicates the “safe” position for all handpieces. Indicates the “forward” position for the PRO6150 Modular Handpiece. Indicates the “open” or “lock” direction for the PRO6175 Oscillator handpiece blade collet mechanism. Consult instructions for use. Non-sterile.

REF

2

Catalog Number. Do not resterilize.

STERILIZE

Manufacturer. EC REP

Authorized representative in the european union.

4

1.6 PowerPro® Pneumatic Modular Handpiece (PRO6150) 1

2

3

4

1.

Attachment Collet-Lock - Twist to release and remove attachments from the handpiece. It is not necessary to twist for insertion of attachment. Simply insert and push attachment to lock in place.

2.

Activation Trigger - Used to activate the handpiece. Depress when the safety/direction lever is in the “forward” or “reverse” position to operate.

3.

Safety/Direction Lever - To operate the handpiece, place in either the “forward” or “reverse” position. Place in the “safe” position prior to connecting or removing any attachment or accessory and during non-use of the handpiece.

4.

Hose Connector - The pneumatic hose (5052-010) connects here.

5

1.7 PowerPro® Pneumatic Oscillator Handpiece (PRO6175) 1 2 3 4

5

6

1.

Blade Locking Collet - Holds and locks the blade in place.

2.

Rotating Head - The rotating head gives the surgeon the ability to position the cutting blade for appropriate surgical access. The oscillator handpiece may contain one of two different rotating heads; either a 4 position, 90 ° indexing head, or an 8 position, 45° indexing head. The 4 position indexing head is no longer manufactured. To position the rotating head, grasp the rotating head, pull it out from the handpiece body, and turn it to the desired position.

3.

Blade Locking Knob - Rotate to open or lock the blade locking collet to insert and lock the blade securely in place.

4.

Activation Trigger - Depress when the safety/direction lever is in the “run” position to operate the handpiece.

5.

Safety/Direction Lever - To operate the handpiece, place in the “run” position. Place in the “safe” position prior to connecting or removing an accessory and during non-use of the handpiece.

6.

Hose Connector - The pneumatic hose (5052-010) connects here.

6

1.8 PowerPro® Pneumatic Reciprocator Handpiece (PRO6185)

1 2 3

4 5 The PowerPro Pneumatic Reciprocator Handpiece is designed to accept Hall® 5052-058 through -061, -073, -179, -258 through -261, -273, -276 and -279 series blades. Refer to the Hall Catalog for specific blade information. 1.

Blade Collet - Insert a blade here. Also used to rotate the blade to any of four (4) positions at 90° intervals for appropriate surgical access. Blade positioning must be done prior to locking the blade in the collet. To rotate, grasp the blade at the base of the collet and rotate to the desired position.

2.

Blade Locking Knob - Rotate counterclockwise to open the collet to insert a blade. Rotate clockwise to lock the blade securely in place.

3.

Activation Trigger - Used to activate the handpiece. Depress when the safety/direction lever is in the “run” position to operate the handpiece.

4.

Safety/Direction Lever - To operate the handpiece, place in the “run” position. Place in the “safe” position prior to connecting or removing an accessory and during non-use of the handpiece.

5.

Hose Connector - The pneumatic hose (5052-010) connects here.

7

2.0

INSTALLATION AND OPERATION

NOTES: 1.

When not in use and prior to connecting or removing attachments and accessories, always place the handpiece in its “safe” position.

2.

The connected attachment (drill or reaming) determines the speed and torque.

2.1 Power Source and Regulator Installation and Operation WARNING: Not for inhalation. Does not support life. For use with powered surgical devices only.

!

Research and experience have shown that water-pumped dry nitrogen is the ideal source for pneumatically-powered surgical instruments. Water-pumped dry nitrogen is 99.97% pure, and will not support combustion or corrosion. Compressed dry nitrogen is recommended as the pneumatic power source. It is available in standard cylinders. Compressed dry nitrogen must meet the following specifications to ensure optimum safety for both patient and instrument. Nitrogen Content: 99.97% pure, dry nitrogen. Quality Assurance: To obtain the quality of gas needed, “water-pumped dry nitrogen, or liquid nitrogen, pumped dry” should be specified. Nitrogen is readily available from gas supply houses in H cylinders holding slightly more than 300 cubic feet (8.50 cubic meters). Initial set-up costs are relatively inexpensive as compared to compressed air. Nitrogen can be placed in the operating room or in a storage area and piped into the operating room. Manifold systems are available to eliminate frequent tank changes. PRECAUTION: Do not exceed 110 psi (7.7 kg/cm2) operating pressure unless a hose longer than the standard 10 ft. Universal Hose (5052-010) or extension hose is used. Add an additional 1 psi for every extra foot of hose.

!

The PowerPro® Pneumatic handpiece should be operated at 110 psi (7.7 kg/cm2) for maximum operating efficiency, and should be monitored by the operating pressure gauge of the regulator. Lower pressure setting can be set for lower speed and torque requirements. Pressure must be set with the instrument running to ensure proper operating pressure. Never start a procedure if the operating pressure gauge indicates less than 500 psi (35.1 kg/cm2) in the tank. Never run the tank pressure below 200 psi (14.0 kg/cm2). The tank should be thoroughly wiped off with disinfectant and draped prior to placement in the operating room. Always have the tank securely fastened to a stable object. 8

1.

Prior to set-up in the operating room, open the tank valve (counterclockwise) slowly and allow enough gas to escape to blow out any debris that may have accumulated in the valve. Stay clear of the opening and the back of the tank during this procedure. Return the valve to the closed position.

2.

Install the regulator with a 1 1/8 inch wrench.

NOTE: The threaded adaptor of the nitrogen regulator is designed to fit nitrogen fittings only. Incompatibility of the regulator and tank indicates a gas source other than nitrogen or an improper regulator for use with a nitrogen tank.

3.

Once the regulator is securely installed, ensure the regulator knob is in the full off position by turning the regulator control knob counterclockwise. SUDDEN PRESSURE EXERTED TO THE REGULATOR MAY CAUSE INTERNAL DAMAGE.

4.

Slowly turn the tank valve fully open (counterclockwise). This will allow nitrogen to pressurize the regulator.

9

5.

Insert the male Schrader end of the hose into the female Schrader on the regulator with an upward thrust.

6.

Operating pressure is established by gradually turning the regulator control knob clockwise. ALWAYS establish the designated pressure on the operating pressure gauge with the instrument running.

To connect the hose to the handpiece: 1.

Place the handpiece in the “safe” position.

2.

Insert the coupling end of the hose into the fitting on the bottom of the handpiece.

3.

Twist the hose coupling to the right (clockwise) and slightly pull on the hose so the internal pins securely engage in the indentations.

4.

Attached to the Universal Hose (5052-010) is the Hall® Hose Handler. This clip allows fixation of the hose to the surgical drape, reducing the problem of the hose slipping off the patient. 10

5.

The Velcro® strap allows the hose to be coiled, thus reducing excess hose length. In addition, the VELCRO strap may be used with any additional hose and/or cable.

Before removing the instrument from the regulator: 1.

Close the tank valve by turning it clockwise.

2.

Activate the instrument to bleed off line pressure.

3.

Turn the pressure regulator knob counterclockwise until it stops.

4.

Turn the female Schrader to the right to disengage the male Schrader fitting.

5.

The hose can then be removed from the connector. Hold the end of the hose securely when disengaging the male Schrader fitting to prevent possible damage to the diffuser.

If the Hall® Pneumatic Connector* is being used: 1.

Locate the button marked “PRESS”.

2.

Depress and hold the button until the audible release of residual gas is completed.

3.

Release the button and remove the hose.

4.

If the hose cannot be easily removed, depress the “PRESS” button again, release it and remove the hose. 11

2.2 Connecting and Removing Attachments All attachments for the PowerPro® Pneumatic Modular Handpiece connect/disconnect in the same manner. For more information, refer to the PowerPro Attachment Instruction Manual or the Information Insert supplied with each attachment. To connect an attachment: 1.

Place the safety/directional lever in the “safe” position.

2.

Orient the attachment shaft to the handpiece opening. Insert the shaft and press them until they snap together.

3.

To disconnect an attachment, twist the attachment collet-locking ring in a clockwise direction and remove the attachment.

2.3 Handpiece Mode Selection and Operation 2.3.1 PowerPro® Pneumatic Modular Handpiece (PRO6150) The PowerPro Pneumatic Modular handpiece, in conjunction with numerous attachments, is used for drilling, and wire and pin driving. It has a variable speed of 0-1250 rpm and a minimum torque of 20 in. lbs. with all drilling, and wire and pin driving attachments. A variable speed of 0-250 rpm and torque of 100 in. lbs. with the 5:1 ratio reaming attachment (identified with a blue-colored ring). 1.

To operate the handpiece, place the handpiece safety/direction lever in either the “forward” or “reverse” position and depress the trigger.

2.

With the safety/direction lever in the “forward” position, depressing the trigger operates the handpiece in the clockwise direction as viewed from the rear of the handpiece. The speed is variably controlled by the trigger.

3.

With the safety/direction lever in the “reverse” position, depressing the trigger operates the handpiece in the counterclockwise direction as viewed from the rear of the handpiece. The speed is variably controlled by the trigger. 12

2.3.2 PowerPro® Pneumatic Oscillator Handpiece (PRO6175) Blade Installation:

To attach a blade: 1. 2.

Place the safety/direction lever in the “safe” position. Rotate the blade locking knob in the direction of the arrow to the “open” position. The blade locking collet will disengage.

3.

Align the blade shank to the desired angle with the blade locking collet. Insert the blade.

4.

Blades can be positioned 45° off the center line in either direction.

5.

Rotate the blade locking knob in the opposite direction of the arrow to lock the blade into place.

WARNING: The blade locking knob must be completely closed to hold the blade firmly in place. 13

!

To remove the blade: 1.

Ensure the safety/direction lever is in the “safe” position.

2.

Rotate the blade locking knob to the “open” position. The blade locking collet will disengage.

3.

Remove the blade.

Handpiece Operation

1.

Position the rotating head to the desired position for the appropriate surgical access. The oscillator handpiece may contain one of two different rotating heads; either a 4 position, 90° indexing head, or an 8 position, 45° indexing head. The 4 position indexing head is no longer manufactured.

2.

Ensure the safety/direction lever is in the “safe” position.

3.

Pull the rotating head out and away from the handpiece body.

4.

Twist the rotating head to the desired position and release the rotating head. Ensure it is locked into place and does not rotate.

5.

Move the safety/direction lever to the “run” position

6.

To activate the handpiece, depress the trigger.

PRECAUTION: When operating the PowerPro® Oscillator Handpiece, let the saw blade do the cutting. Too much force will bind the blade which can damage the handpiece. 14

!

2.3.3 PowerPro® Pneumatic Reciprocator Handpiece (PRO6185) Blade Installation:

1.

To attach a blade:

2.

Place the safety/direction lever in the “safe” position.

3.

Rotate the blade locking knob counterclockwise to open the blade collet.

4.

Completely insert the blade shank.

15

5.

The rotating head may be set in any of 4 positions at 90° intervals for the appropriate surgical access. Position the blade to the desired position by grasping the blade at the base of the collet and rotating it to the desired position.

6.

Rotate the blade locking knob clockwise to lock the blade into place.

WARNING: The blade locking knob must be completely closed to hold the blade firmly in place. 7.

!

To operate the handpiece, move the safety/direction lever to the “run” position and depress the trigger.

PRECAUTION: Do not operate the Reciprocator Handpiece with the collet in the “open” position or without a blade locked in the collet. Damage will occur.

!

To remove the blade: 1.

Ensure the safety/direction lever is in the “safe” position.

2.

Rotate the blade locking knob to the “open” position. The blade locking collet will disengage.

3.

Remove the blade.

16