HS JOHN WEISS

Forceps

Reusable Micro Forceps and Scissors Care, Maintenance and Reprocessing Guidelines

2 Pages

Preview

Page 1

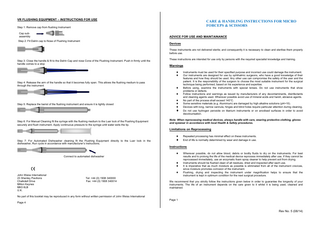

VR FLUSHING EQUIPMENT – INSTRUCTIONS FOR USE

CARE & HANDLING INSTRUCTIONS FOR MICRO FORCEPS & SCISSORS

Step 1: Remove cap from flushing Instrument Cap subassembly

ADVICE FOR USE AND MAINTAINANCE

Step 2: Fit Delrin cap to Nose of Flushing Instrument

Devices These instruments are not delivered sterile; and consequently it is necessary to clean and sterilise them properly before use.

Step 3: Close the handle & fit to the Delrin Cap and nose Cone of the Flushing Instrument. Push in firmly until the handle comes to a stop

These instructions are intended for use only by persons with the required specialist knowledge and training.

Warnings ♦ ♦

Step 4: Release the arm of the handle so that it becomes fully open. This allows the flushing medium to pass through the instrument

♦ ♦

Step 5: Replace the barrel of the flushing instrument and ensure it is tightly closed

♦ ♦ ♦

♦ Step 6: For Manual Cleaning fit the syringe with the flushing medium to the Luer lock of the Flushing Equipment securely and flush instrument. Apply continuous pressure to the syringe until water exits the tip.

Instruments must be used for their specified purpose and incorrect use could damage the instrument. Our instruments are designed for use by ophthalmic surgeons, who have a good knowledge of their features and how they should be used. Any other use can compromise the safety of the user and the patient. It is the responsibility of the surgeon to choose the most suitable instrument for the surgical technique being performed, based on his experience and expertise. Before using, examine the instruments with special lenses. Do not use instruments that show problems or defects. Follow instructions and warnings as issued by manufacturers of any decontaminants, disinfectants and cleaning agents used. Wherever possible avoid use of mineral acids and harsh, abrasive agents. No part of the process shall exceed 140°C. Some sensitive materials (e.g. Aluminium) are damaged by high alkaline solutions (pH>10). Devices with long, narrow cannula, hinges and blind holes require particular attention during cleaning. Do not use hydrogen peroxide on titanium instruments or on anodised surfaces in order to avoid decolourisation.

Note: When reprocessing medical devices, always handle with care, wearing protective clothing, gloves and eyewear in accordance with local Health & Safety procedures.

Limitations on Reprocessing ♦ Step 7: For Automated Dishwasher cleaning fit the Flushing Equipment directly to the Luer lock in the dishwasher, Run cycle in accordance with manufacturer’s instructions.

♦

Repeated processing has minimal effect on these instruments. End of life is normally determined by wear and damage in use.

Instructions Connect to automated dishwasher

♦

♦ ♦ John Weiss International 23 Shenley Pavilions Chalkdell Drive Milton Keynes MK5 6LB U.K.

♦ Tel: +44 (0) 1908 340000 Fax: +44 (0) 1908 340014

Wherever possible, do not allow blood, debris or bodily fluids to dry on the instruments. For best results and to prolong the life of the medical device reprocess immediately after use. If they cannot be reprocessed immediately, use an enzymatic foam spray cleaner to help prevent soil from drying. Instruments should be flushed clean of all residues, dried and inspected after each use. It is imperative that as much moisture as possible is eliminated from all of the instrument crevices, since moisture promotes corrosion of the instrument. Flushing, drying and inspecting the instrument under magnification helps to ensure that the instrument is kept in optimum condition for the next surgical procedure.

We recommend that you strictly follow the instructions given below in order to guarantee the longevity of your instruments. The life of an instrument depends on the care given to it whilst it is being used, cleaned and maintained.

No part of this booklet may be reproduced in any form without written permission of John Weiss International Page 4

Page 1

Rev No. 5 (08/14)

Cleaning : Manual The minimal cleaning routine recommended is as follows and should be done post procedure without delay. Instruments should be both flushed and dried using the specially designed Flushing Equipment (See Instructions for Use on Page 4) then following the 7 steps below:1)

Fill the syringe with the appropriate substance (i.e. distilled water, alcohol or air), for maximum results John Weiss recommends that Maximum Recovery Diluents is used. Flush the instrument in accordance with the Flushing Equipment Instructions for Use. Repeat this process five times. Do not flush the instrument with any fluid that might leave residue, such as tap water or saline.

2)

The instrument should be flushed thoroughly with distilled water.

3)

Remove the distilled water by flushing the instrument through with 70% alcohol.

4)

Blow one or two syringes of air through the instrument to remove most of the alcohol.

5)

Remove instrument from Flushing Equipment and clean the exterior of the instrument handle and shaft carefully with a moist surgical sponge (moist with Isopropyl alcohol). Avoid direct contact with the delicate tip of the instrument.

6)

Wipe the exterior of the instrument dry.

7)

After cleaning, the instrument should be carefully inspected under magnification for any possible wear or damage prior to sterilisation.

Cleaning : Automated ♦

♦ ♦ ♦

Use only either CE marked or validated washer-disinfector machines and low-foaming, non-ionising cleaning agents and detergents following the manufacturers' instructions for use, warnings, concentrations and recommended cycles. Insert the instruments into the Flushing Equipment following the Instructions for Use shown on Page 4. Carefully load the instrument and Flushing Equipment into the dishwasher, connecting the leur lock of the Flushing Equipment to the dishwasher leur lock Run dishwasher cycle in accordance with manufacturers instructions.

Cleaning : Inspection After cleaning, visually inspect all surfaces, cannulations, ratchets, joints, holes and lumens for complete removal of soil and fluids. If ANY soil or fluid is still visible, return the instrument for repeat decontamination.

Maintenance

Note: If an instrument is returned to the manufacturer / supplier, the instrument must be decontaminated and sterilised and be accompanied with the relevant documented evidence.

Packaging All instruments to be packed following local protocol in accordance with BS standards.

Sterilisation Instruments can be sterilised using the following methods:100% ETO Cycles Concentration ETO: Temperature: Exposure time: Humidity:

850 ± 50mg/l 37°C - 47°C 3-4 hours 70% RH minimum

Stream autoclaving Sterilizer type Sample config.: Temperature: Exposure time:

Gravity displacement wrapped 121°C to 123°C 15 to 30 minutes

Prevacuum wrapped 132°C to 135°C 3 to 4 minutes

'Flash' autoclaving Sterilizer type: Sample config.: Temperature: Exposure time:

Gravity displacement unwrapped 132°C 3 minutes

Prevacuum unwrapped 132°C 3 minutes

Above-mentioned sterilization cycles represent industry standards and should be capable of producing a sterile device. Due to variations in sterilization equipment and device bioburden in clinical use, Eye Technology is not able to produce specific cycle parameters. It is the responsibility of each user to perform a validation and verification of the sterilisation cycle to ensure an adequate sterility assurance level for our products. Special notes for Silicone Oil: Silicone oil is extremely difficult to completely remove from the silicone accessories. Therefore, if silicone oil is used in the surgical procedure, all silicone parts that come in contact with the silicone oil, should be replaced.

Storage Ensure instruments are dry before storage, and stored in dry, clean conditions at an ambient room temperature.

Additional Information Other forms of cleaning (i.e. ultrasonic) are available. However, always follow the instructions for use as issued by the manufacturer and always consult with them if in any doubt over the suitability of any process used.

Apply surgical grade lubricants to hinges, joints and moving parts as per the lubricant manufacturer's instructions.

Inspection and Function Testing ♦

♦ Page 2

Visually inspect and check all instruments for damage and wear; cutting edges are free of nicks and present a continuous edge; jaws and teeth align correctly; all articulated instruments have smooth movement without excess play; locking mechanisms fasten securely and close easily; long, slender instruments are not distorted; any component parts fit and assemble correctly with mating components. Remove for repair or replacement any blunt, worn out, flaking, fractured or damaged instruments.

NOTE: It is the responsibility of the reprocessor to ensure that the reprocessing as actually performed using equipment, materials and personnel in the reprocessing facility achieve the desired result. This requires validation and routine monitoring of the process. Likewise any deviation by the reprocessor from the instructions provided must be properly evaluated for effectiveness and potential adverse consequences.

Page 3