2 Pages

Preview

Page 1

E-Type Contra Angle Sheath

EC/ER4/ER10/ER16/ER64/ER128 ECM/ER4M/ER10M/ER16M/ER64M/ER128M

OM-C0341E 002

CAUTION · When operating the Product always consider the safety of the patient. · Place the most priority for the safety of all patients. · When it is found abnormal during use, stop immediately. Do not use, and report to the dealer that was purchased from. · Do not disassemble the sheath except for the referred to herein, nor alter. · Do not impact on the sheath, nor drop onto hard surface. · Always watch for vibration, sound, temperature rise, bur wobble, and other abnormalities. · Disconnect the sheath after the driver unit is in complete stop. · The device accepts NSK Y-type heads. · When the sheath might be subjected to a high torque, such as in implant application, use the I-type sheath (ER16i, ER20i, ER32i, ER64i, ER256i) with I-type head. · In case blood or contaminants entered the head, immediatery remove the head cartridge and the transmission gear. Clean and lubricate them. Assemble carefully. · Do not wipe with, or clean or immerse in, high acid water or sterilizing solutions.

1. Speed Allowable Max.Speed······40,000min-1 (rpm) Sheath Type

Motor Speed

Bur Speed (min-1) EC ECM

ER4 ER4M

ER10 ER16 ER10M ER16M

40,000

40,000

10,000

4,000

2,500

625

312

30,000

30,000

7,500

3,000

1,850

469

234

20,000

20,000

5,000

2,000

1,250

312

156

10,000

10,000

2,500

1,000

625

156

78

(min-1)

ER64 ER128 ER64M ER128M

Note: The bur speed might be slightly lower than the theoretical speed as given above, due to a loss at the gear train.

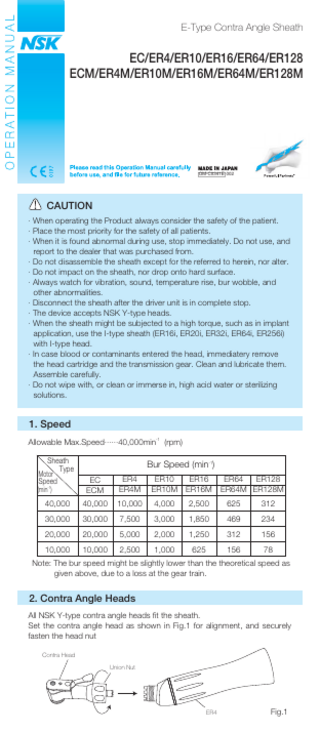

2. Contra Angle Heads All NSK Y-type contra angle heads fit the sheath. Set the contra angle head as shown in Fig.1 for alignment, and securely fasten the head nut Contra Head Union Nut

ER4

Fig.1

3.Lubrication Supply PANA-SPRAY Plus / PANA-SPRAY after each use and/or before autoclaving. 1 Push E-type spray nozzle attachment over the PANA-SPRAY Plus

nozzle until it firmly seats. 2 Shake the can 3-4 times to well mix lubricant and propellant. 3 Insert the E-type spray nozzle in the rear of the handpiece and

spray for approximately 2-3 seconds until the oil comes out of the handpiece head or nose. E-type Spray Nozzle

Handpiece

PANA-SPRAY Plus / PANA-SPRAY

Fig.2

PANA-SPRAY Plus / PANA-SPRAY

CAUTION · Be sure to hold the handpiece firmly to prevent the handpiece from slipping out by the spray pressure when lubricating. · Keep the spray can upright.

4.Cleaning and Sterilization The products listed below are washable with Thermo Disinfector. ECM, ER4M,ER10M, ER16M, ER64M, ER128M Sterilization by autoclaving is recommended. Sterilization is required first time you use and after each patient as noted below. Autoclaving procedure 1 Brush off dirt and wipe clean with alcohol-soaked cloth or paper towel. 2 Remove reduction sheath from the motor and lubricate. Ref.3 Lubrication. 3 Insert into a sterilization bag and seal it. 4 Autoclavable up to a max. 135°C.

ex.) Autoclave for 20 min. at 121°C, or 15 min. at 132°C. 5 Keep the handpiece in the sterilization bag to keep it clean until you use it.

* Sterilization at 121°C for more than 15 minutes is recommended by EN13060 or EN ISO17665-1.

CAUTION on Sterilization · Heating element may be located at the bottom of the chamber, and the temperature there locally may exceed the set value. Place the handpiece on the central or upper tray. · Do not autoclave the handpiece, even when it is bagged, together with other instruments, from which chemicals are not sufficiently cleaned. This is to avoid discoloration and/or damage the plating of the handpiece. The EU directive 93/42/EEC was applied in the design and production of this medical device.

’10.02.05 S