Teleflex Medical

500 x 300 x 120 mm Cleaning and Storage Basket

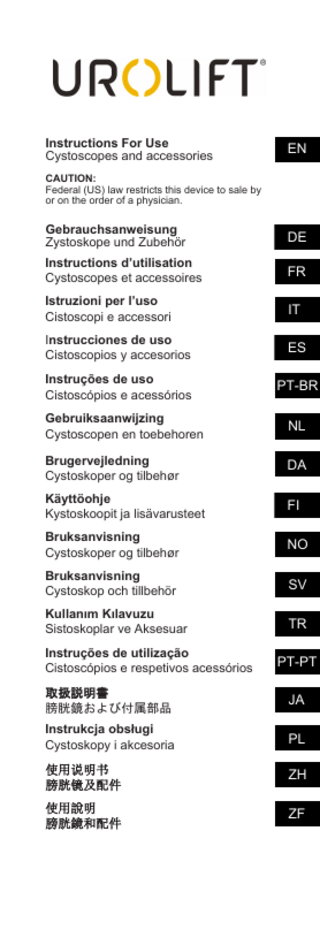

UROLIFT Cystoscopes and accessories Instructions for Use

376 Pages

Preview

Page 1

Instructions For Use Cystoscopes and accessories

EN

CAUTION: Federal (US) law restricts this device to sale by or on the order of a physician.

Gebrauchsanweisung Zystoskope und Zubehör

DE

Instructions d’utilisation Cystoscopes et accessoires

FR

Istruzioni per l’uso Cistoscopi e accessori

IT

Instrucciones de uso Cistoscopios y accesorios

ES

Instruções de uso Cistoscópios e acessórios

PT-BR

Gebruiksaanwijzing Cystoscopen en toebehoren

NL

Brugervejledning Cystoskoper og tilbehør

DA

Käyttöohje Kystoskoopit ja lisävarusteet

FI

Bruksanvisning Cystoskoper og tilbehør

NO

Bruksanvisning Cystoskop och tillbehör

SV

Kullanım Kılavuzu Sistoskoplar ve Aksesuar

TR

Instruções de utilização Cistoscópios e respetivos acessórios

PT-PT

取扱説明書 膀胱鏡および付属部品

JA

Instrukcja obsługi Cystoskopy i akcesoria

PL

使用说明书 膀胱镜及配件

ZH

使用說明 膀胱鏡和配件

ZF

TPA361-233-149 Version: F 2021 - May - 4

Instructions For Use | 4 - May - 2021 | Version: F

Page 2 of 376

Content 0

0.1

1

2

3

4

Page

Important Information about this Document... 20 General Information... 20

0.2

List of Products...20

0.3

Target User Group Qualifications...20

0.4

Using and Storing this Document...20

0.5

Safety Messages in this Document...20

0.6

Symbols Used in this Document... 21

General Information about the Device... 21 1.1

Indications for Use...21

1.2

Contraindications... 21

1.3

Device Descriptions... 21

1.4

Symbols Used on the Devices and Packaging...22

1.5

Obligation to Report Serious Incidents...23

General Safety Information... 23 2.1

Basic Safety Information... 23

2.2

Electrical Equipment Safety Requirements (IEC 60601)... 24

Device Operation Including Inspection and Assembly...24 3.1

Safety Instructions... 24

3.2

Staff Qualifications...26

3.3

Initial Receipt of Device...26

3.4

Device Inspection and Test... 26

3.5

Device Assembly... 27

3.6

Device Pre-Cleaning...28

Reprocessing... 28 4.1

General Information... 28

4.2

Safety Instructions... 29

4.3

Staff Qualifications...30

4.4

General Guidelines for Reprocessing... 30

4.5

Typical Reprocessing Sequences (Process Flows)... 31

4.6

Detailed Reprocessing Instructions... 31 4.6.1 Manual Cleaning...31 4.6.2 Manual Cleaning with Disinfection...32 4.6.3 Automated Cleaning (with Thermal Disinfection)...33 4.6.4 High Level Disinfection (HLD)... 34 4.6.5 Sterilization... 35

5

6

Maintenance and Repairs... 36 5.1

Common Issues and Solutions... 36

5.2

Repair... 36

Product Data... 37 6.1

Technical Data...37 6.1.1 Cystoscope 2.9 mm...37 6.1.2 Cystoscope 4.0 mm...37 6.1.3 Sheath...37 6.1.4 Visual obturator...37

6.2

Ambient Conditions... 37

6.3

Spare Parts and Accessories... 38

7

Disposal... 38

8

DISCLAIMER OF WARRANTY... 39

9

Appendix A: Customer Service Contact Information...39

Instructions For Use | 4 - May - 2021 | Version: F

Page 3 of 376

0 Important Information about this Document 0.1 General Information

0

Important Information about this Document

0.1

General Information

These instructions for use are an integral component of the device and contain the information required by users and operators for safe and proper use. These instructions for use do not describe endoscopic procedures or techniques during surgery.

0.2

List of Products

These instructions for use apply to the following devices and their included accessories: UL-SCOPE / UL-SCOPE-FE cystoscope, 2.9 mm diameter x 365 mm length, 0° direction of view, 85° field of view UL-SCOPE4 / UL-SCOPE4-FE cystoscope, 4 mm diameter x 302 mm length, 30° direction of view, wide angle UL-SHEATH sheath, 20 Fr, with 2 tube connectors (Luer lock and Luer lock with stopcock) UL-VO visual obturator, 20 Fr These instructions for use are an integral component of the product set and contain all the information required by users and operators for safe and proper use. These instructions for use do not describe endoscopic procedures or techniques during surgery. FE Factory Exchange (Factory Exchange): Devices with a part number ending in „FE“ have been repaired to meet product specifications.

0.3

Target User Group Qualifications

These instructions for use are to be used by physicians, medical support personnel, and reprocessing personnel knowledgeable about the use, handling, and reprocessing of the device.

0.4

Using and Storing this Document

This operating manual must be stored in a defined location so that it may be accessed at all times by the target group. In the event of the sale of this device or its relocation, this document must accompany the device.

0.5

Safety Messages in this Document

Safety instructions are listed at the start of each chapter that contains instructions that carry a specific risk. Safety instructions are listed within each chapter when applicable, directly prior to steps that carry a specific risk. Take time to read these safety messages carefully and bear them in mind when performing the activities concerned. The severity of the potential risk is expressed by the signal word in the beginning of the message. WARNING! refers to a risk that could lead to death or serious injury. CAUTION! refers to a risk that could lead to minor or moderate injury. NOTICE! refers to activity that carries a risk of material damage. For every risk, the signal word will be followed by the nature and origin of the risk, potential consequences of non-observance, and preventive action.

Instructions For Use | 4 - May - 2021 | Version: F

Page 20 of 376

0 Important Information about this Document 0.6 Symbols Used in this Document

0.6

Symbols Used in this Document General warning sign

Biohazard warning sign, risk of infection

Hot surfaces warning sign

1

General Information about the Device

1.1

Indications for Use

The cystoscopes, sheath, visual obturator, working bridge and grasper are indicated to provide the user with the means for endoscopic diagnostic and therapeutic surgical procedures. Examples for the use of the devices include the visualization and manipulation of anatomy as the surgeon deems appropriate. The devices are intended to be used in general urological surgery through a minimally invasive approach by utilizing natural orifices to access the surgical site.

1.2

Contraindications

Contraindications may exist with respect of the patient’s general condition or the specific presenting disease. The decision to perform a procedure is the responsibility of the treating physician and should be made on the basis of an individual benefit/risk analysis.

1.3

Device Descriptions

These instructions for use apply to each of the following devices. UL-SCOPE / UL-SCOPE-FE and UL-SCOPE4 / UL-SCOPE4-FE

Figure 1-1: Telescope (UL-SCOPE or UL-SCOPE4) 1 Eyepiece 2 Light Guide Connector (ACMI) 3 Light Guide Adapter, Storz (AN00023) 4 Light Guide Adapter, Wolf (AN00023) 5 Telescope Shaft 6 Telescope Tip UL-SHEATH

Figure 1-2: 20 Fr Sheath (UL-SHEATH). The numbers at the proximal end of the sheath indicate the outer diameter of the sheath and the maximum outer diameter of an instrument that is compatible with the sheath (number surrounded by a circle).

Instructions For Use | 4 - May - 2021 | Version: F

Page 21 of 376

1 General Information about the Device 1.3 Device Descriptions

1 Connector 2 Irrigation Connectors 3 Tube Connector for Luer Lock (AN00032) (Table 6-1) 4 Tube Connector for Luer Lock with Stopcock (AN00031) (Table 6-1) 5 Atraumatic tip UL-VO

Figure 1-3: Visual Obturator (UL-VO) 1 2.9 mm Telescope Connector 2 20 Fr Sheath Connector 3 Atraumatic tip

1.4

Symbols Used on the Devices and Packaging The device is suitable for autoclave sterilization.

XXXX

CE marking. The product meets the requirements of applicable EU guidelines. Products falling within the higher risk classes, which require inspection by a notified body as part of the certification process, bear both the CE mark and the identification number of the notified body that completed the inspection. Part Number

Serial Number

Lot Number

Quantity in Package

Direction of View

Medical Device Manufacturer

Date of Manufacture

Caution

Non-sterile, sterilize prior to each use

Instructions For Use | 4 - May - 2021 | Version: F

Page 22 of 376

1 General Information about the Device 1.4 Symbols Used on the Devices and Packaging The Cystoscopes and Accessories are MR unsafe

Permissible storage and transport temperature

Permissible relative air humidity during storage and transport Permissible atmospheric pressure during storage and transport CAUTION: Federal (US) law restricts this device to sale by or on the order of a physician.

1.5

Obligation to Report Serious Incidents

Any serious incident that has occurred in relation to the device must be reported to the manufacturer and the competent authority of the Member State in which the user and/or patient is established.

2

General Safety Information

2.1

Basic Safety Information

Our products are developed and manufactured to the highest quality standards. Risks can nonetheless arise during initial use, reprocessing, or maintenance. Therefore, it is important that you read through these instructions for use carefully and observe the warnings indicated. Each device must be inspected prior to each use and used only if they are free from damage and in full working order. Follow the instructions for use for all devices that are to be used in conjunction with this device. WARNING! This device is supplied in a non-sterile condition, which carries a risk of infection. Carry out sterile processing of the device and its accessories prior to first use. WARNING! Unauthorized modifications to the device carry a risk of serious injury. Do not make any unauthorized modifications. WARNING! Component failure during a surgical procedure carries a risk to the patient. Keep spares on hand for emergency replacement. WARNING! High-intensity light source. Risk of injury to eyes. Do not look directly into the light exit at the distal end of the telescope. WARNING! Magnetic resonance imaging (MRI). Magnetic force, electromagnetic interactions, heating of metal components. Do not operate the device in the vicinity of MRI scanners. WARNING! Using the device during operation of a defibrillator carries a risk to persons. Before discharging a defibrillator, remove device from the operating field. CAUTION! Rough handling may lead to damage of the device and therefore carries a risk to the patient. Handle the device with appropriate care. If the device is dropped or subjected to high mechanical stress, stop using it and send to the manufacturer for inspection. WARNING! Improper handling, maintenance, and use carries a risk to the patient and user, or can lead to premature wearing of the device.

Instructions For Use | 4 - May - 2021 | Version: F

Page 23 of 376

2 General Safety Information 2.2 Electrical Equipment Safety Requirements (IEC 60601)

2.2

Electrical Equipment Safety Requirements (IEC 60601)

The device is intended to be used in combination with light sources and camera systems that are compliant with the requirements for applied parts classified as type BF (that is parts offering increased protection against electric shock), or as type CF according to IEC 60601-1. This insulation barrier can be realized by the medical electrical devices themselves or by the connecting cables to the telescope and must be assured for every connection between the telescope and connected devices.

3

Device Operation Including Inspection and Assembly

3.1

Safety Instructions

WARNING Interactions between devices in simultaneous use Risk to the patient and user, image distortion, damage to the device Ensure that all the devices in use are compliant with the requirements for applied parts classified as type BF according to IEC 60601-1 Observe the labeling and instructions for use of the devices used

WARNING Displaying a recorded image instead of the live image or an altered image orientation Risk to the patient Ensure that the monitor is displaying the live image from the endoscopic camera Ensure that the live image is displayed in the correct orientation (not mirrored)

WARNING Use of non-sterile parts Infection risk for the patient Use only properly reprocessed telescopes and endoscopic accessories Accessories supplied in a non-sterile condition (e.g. single-use sealing caps) must be subject to sterile processing before use Always carry out a visual inspection prior to use Anchor the light guide in the operating field and secure against slipping, allowing some slack for maneuvering

WARNING Recontamination resulting from improper handling Infection risk for the patient Adhere to the infection control practices that are in place

Instructions For Use | 4 - May - 2021 | Version: F

Page 24 of 376

3 Device Operation Including Inspection and Assembly 3.1 Safety Instructions

WARNING Patient leakage currents may be additive When energized endoscopes are used with energized endotherapy devices, patient leakage currents may be additive. This is particularly important if a type CF applied part endoscope is used, in which case a type CF applied part energized endotherapy device should be used in order to minimize total patient leakage current

WARNING Interactions between devices in simultaneous use (e.g. lasers, electrosurgery) Risk to the patient and user, image interference, damage to the device Ensure that all the devices in use meet at minimum the requirements classified as type BF according to IEC 60601-1 Observe the labeling and instructions for use of the devices used Avoid direct contact between the endoscope and conductive parts with active RF electrodes Do not activate RF electrodes in the vicinity of flammable gases or liquids Before using RF devices, ensure that all potentially explosive gas mixtures and liquids have been extracted

CAUTION High temperatures resulting from light source usage* Irreversible tissue damage to patient or undesirable coagulation, user injury, material damage Use only light guides that are suitable for use with the endoscope Avoid the prolonged use of intense light Always use sheath with endoscope You should always use the lowest possible light output setting that will allow you to illuminate the target area Do not touch the light source in the vicinity of the lamp Do not touch light guide connections Do not allow the distal end of the endoscope to come into contact with patient tissue or with combustible or heat-sensitive materials Do not exceed the maximum permitted ambient conditions for the endoscope When there is potential for the shaft of the endoscope to come in direct contact with body tissues (e.g. confined anatomical space), do not maintain the same position for extended periods of time (> 10 minutes) * Applied part as per IEC 60601-1 can reach temperatures of > 41 °C (106 °F).

Instructions For Use | 4 - May - 2021 | Version: F

Page 25 of 376

3 Device Operation Including Inspection and Assembly 3.1 Safety Instructions

CAUTION Coupling laser beams in the endoscope Damage to the eyes caused by looking directly into the eyepiece Wear laser safety glasses

NOTICE Improper handling Risk of damage to the device Set down carefully without bending or knocking Avoid scratching the surface Take care when removing instruments from the operating field

3.2

Staff Qualifications

The device may be used only by physicians, surgeons, and surgical assistants who have received instruction in how to use the device and who have the requisite training, knowledge, and practical experience in the procedure to be performed as defined by the provisions in place at the site of service.

3.3

Initial Receipt of Device

Complete a visual inspection (section 3.4) upon receipt of the device. Contact Customer Service (Appendix A) if the device does not meet the inspection criteria. Note: The original packaging should be retained and reused when returning a device for servicing.

3.4

Device Inspection and Test

Complete a visual inspection prior to each use of the Telescope Check the telescope and all the components to be used for external damage. Do not use the device if it has any sharp edges or corners, defects, or rough surfaces that might cause injury to the patient. Check that the fiber optics in the telescope are in full working order. Do this by holding the distal end toward a bright light (not a cold light source) and the light guide connector toward your eyes. Gently move the telescope from side to side, taking note of the brightness of the fibers. If more than 20 % of the fibers remain dark, the telescope must not be used and a repair must be arranged. Check that the glass surfaces and fiber optic end faces of the telescope are clean and smooth. Do not use the telescope if the surfaces are soiled or scratched. Set aside the telescope and follow the steps described in Section 5.1. Make sure you can see a clear, bright, complete image. Look through the eyepiece and assess the image quality. Do not use the telescope if the image is yellowed, dark, speckled, or cropped. Set aside the telescope and follow the steps described in Section 5.1. Check that all the equipment to be used for the procedure is mutually compatible. Operate all equipment according to manufacturer's instructions. Only use electrical equipment with an isolation barrier for protecting against electric shock; equipment must comply with the requirements for applied parts classified as type BF according to IEC 60601-1 (see Section 2.2 "Electrical Equipment Safety Requirements"). Complete a Functional Test Prior to Each Use of the Device Connect the camera and the light source to the telescope. Verify that the connections are secure. Switch on all the system components that you intend to use for the procedure.

Instructions For Use | 4 - May - 2021 | Version: F

Page 26 of 376

3 Device Operation Including Inspection and Assembly 3.5 Device Assembly Direct the camera head at a nearby object in the room and focus the image. Verify that you are able to achieve a sharp, bright, good quality image. Do not use the system if the image contains vertical lines or color variations, flickers, or you are unable to achieve a sharp, bright, good quality image. Connect the fittings of all of the mating equipment items. Verify that the connections are secure.

3.5

Device Assembly

The Visual Obturator is to be used with the 2.9 mm Telescope (ULSCOPE). Align the swivel joints on the Telescope Connection and Sheath Connection on the Visual Obturator such that the rotatable pieces snap into place. Align the Visual Obturator and the Sheath so that the two zeros are across from each other (Figure 3-1).

Figure 3-1: Visual Obturator and Sheath in alignment. Push the Visual Obturator completely into the Sheath (Figure 3-2).

Figure 3-2: Visual Obturator and Sheath engaged, ready for the lever to be locked. Lock the Visual Obturator into the Sheath by rotating the lever on the Sheath connector one-quarter turn.

Figure 3-3: Visual Obturator and outer sheath are tightly joined. Insert the Telescope into the Telescope Connector on the Visual Obturator. Align the Telescope light guide connector with the engraved line on the Visual Obturator.

Instructions For Use | 4 - May - 2021 | Version: F

Page 27 of 376

3 Device Operation Including Inspection and Assembly 3.6 Device Pre-Cleaning

Figure 3-4: Telescope light guide connector aligned with the engraved line on the Telescope Connector of the Visual Obturator. Push the Telescope completely into the Visual Obturator. Lock the Telescope into the Visual Obturator by rotating the lever on the Telescope Connector one-quarter turn (Figure 3-5).

Figure 3-5: Telescope and Visual Obturator are engaged, the lever is locked. Basic assembly is complete (Figure 3-6).

Figure 3-6: Complete Assembly of Telescope, Visual Obturator and Sheath. To connect the Light Guide, screw the appropriate adapter to the Light Guide connector on the Telescope (Figure 1-1). Screw or press the Light Guide onto the Light Guide connector. Attach the free end of the Light Guide to the light source. Pull gently to verify that all components are securely connected (Figure 3-6). The device is now assembled and ready for the intended use.

3.6

Device Pre-Cleaning

Pre-clean the device immediately after use as follows: Unlock and fully separate all devices and detach all removable parts. NOTICE! The eyepiece cup is not removable. Prepare enzymatic cleaning solution per the manufacturer’s instructions. For details on cleaning agents see section 4.6. Pre-clean all used parts of the fully disassembled device at the conclusion of the procedure by wiping with a lint-free wipe wetted with an enzymatic cleaning solution until visibly clean. Arrange for reprocessing. All devices should be reprocessed within six hours.

4

Reprocessing

4.1

General Information

The instructions provided in this document include multiple methods of device reprocessing. Reprocessing procedures may be subject to institutional, local, and national regulations and standards. It is the responsibility of the end user to select and adhere to the appropriate methods in accordance with all relevant requirements. If particular instructions are specific to reprocessing within the United States or outside of the United States, a note will be used to indicate the relevant geography.

Instructions For Use | 4 - May - 2021 | Version: F

Page 28 of 376

4 Reprocessing 4.2 Safety Instructions

4.2

Safety Instructions

WARNING Suspicion of product contact with pathogens causing Creutzfeldt-Jakob Disease - reprocessing of contaminated product is not possible Risk of cross-contamination during reprocessing Do not reprocess products suspected of being crosscontaminated Dispose of products suspected of being cross-contaminated

WARNING Disinfection Risk to patient Cidex OPA is contraindicated for patients with a history of bladder cancer

CAUTION Improper cleaning and disinfection Risk to patient due to inadequate cleaning and disinfection, damage to the device If automated cleaning and disinfection equipment is used, it must meet the performance requirements of ISO 15883-1 Load the device in such a way as to ensure that all contents are rinsed and cleaned fully (no rinsing ‘blind spots’) Connect all instruments with lumens and channels directly to the dedicated ports on the reprocessing tray or the automated washer/disinfector Disassemble all valves on instruments Ensure proper maintenance of cleaning and disinfection equipment Only use cleaning and disinfecting media that are approved for the device The devices must be pre-cleaned immediately after use and reprocessed within 6 hours When pre-cleaning, do not use fixing temperatures in excess of 45 °C When pre-cleaning, do not use fixing detergents or disinfectants (active ingredients: aldehyde, alcohol)

NOTICE Damage from contact with chloride-based solutions Corrosion and destruction of the device Avoid contact with chloride-based solutions as contained for example in: surgical residue, tinctures, pharmaceutical products, saline solutions and cleaning and disinfection solutions After contact with chloride-based solutions, rinse devices thoroughly with deionised water and dry completely

Instructions For Use | 4 - May - 2021 | Version: F

Page 29 of 376

4 Reprocessing 4.3 Staff Qualifications

NOTICE Damage from ultrasonic cleaning Damage to telescope Do not expose telescope to ultrasonic cleaning bath

NOTICE Unsuitable detergents and process chemicals Corrosion damage, premature aging and visible material deterioration Only use cleaning and disinfecting media that are approved for the device Only use process chemicals that are compatible with the device’s materials according to the chemical manufacturer’s recommendations Follow all the chemical manufacturer’s application specifications regarding temperature, concentration and contact time Do not use process chemicals that may cause stress cracking or brittleness of plastic materials

4.3

Staff Qualifications

The qualifications required by personnel responsible for the reprocessing and sterilization of medical devices are regulated by law in most countries. The reprocessing of the devices must be performed by qualified personnel who have the necessary knowledge and expertise.

4.4

General Guidelines for Reprocessing

The device has been validated to multiple processing methods (Table 4-1). It is the operator’s responsibility to introduce, document, implement, and maintain a validated reprocessing procedure and to make sure the equipment used for reprocessing is properly installed and maintained. Users should wear personal protective equipment during reprocessing. The device must be thoroughly cleaned at the start of reprocessing. It is essential that the sterilization and/or disinfection medium reach all parts of the device. New and recently repaired devices must undergo the entire reprocessing procedure prior to their initial use. Table 4-1: Validated Reprocessing Methods Product

Manual Cleaning

Manual Cleaning with Disinfection

Automated Cleaning (with Thermal Disinfection)**

High Level Disinfection (HLD)

Sterilization

Enzymatic Enzymatic Alkaline Cidex OPA 134 ºC, cleaner cleaner detergent 12 minutes, 3 minutes 2-5 minutes, 2-5 minutes, @ 60 ºC; 3x rinse* minimum* 3x rinse* rinse, water (section / 132 °C (section Cidex OPA rinse @ 4.6.4) 4 minutes 4.6.1) 12 minutes, 90 ºC* minimum*, 3x rinse* (section (section (section 4.6.3) 4.6.5) 4.6.2) ULSCOPE

X

X

X

X

X

ULSCOPE4

X

X

X

X

X

Instructions For Use | 4 - May - 2021 | Version: F

Page 30 of 376

4 Reprocessing 4.5 Typical Reprocessing Sequences (Process Flows)

Product

Manual Cleaning

Manual Cleaning with Disinfection

Automated Cleaning (with Thermal Disinfection)**

High Level Disinfection (HLD)

Sterilization

ULSHEATH

X

X

X

X

X

UL-VO

X

X

X

X

X

* Refer to section number listed in box for detailed instructions.

4.5

Typical Reprocessing Sequences (Process Flows)

Reprocessing procedures may be subject to institutional, local, and national regulations and standards. The Reprocessing Sequences illustrated below are typical in the indicated geography. Typical Reprocessing Sequence in the United States Pre-Cleaning Immediately After Use (Section 3.6) Manual or Automated Cleaning (Section 4.6.1 or 4.6.3) Sterilization or HLD (Section 4.6.5 or 4.6.4) Typical Reprocessing Sequence in Europe and Australia Pre-Cleaning Immediately After Use (Section 3.6) Manual Cleaning with Disinfection or Automated Cleaning with thermal disinfection (Section 4.6.2 or 4.6.3) Sterilization (Section 4.6.5)

4.6

Detailed Reprocessing Instructions

4.6.1

Manual Cleaning

Follow the manufacturer’s instructions when preparing the cleaning solution. Manual Cleaning validation was performed with Cidezyme/Enzol (Johnson & Johnson). NOTICE! Damage resulting from rough handling. Telescopes contain glass rods that are extremely fragile. Handle the device with care. Do not bump or bend. Set down with care. NOTICE! (Telescopes) Scratch-sensitive surfaces. Risk of abrasion. Do not use metal brushes, metal objects, or abrasive cleaners. To remove soiling on optical surfaces use soft materials with cleaning solution only. NOTICE! Scratch-sensitive surfaces. Risk of corrosion due to abrasion. Do not use metal brushes, metal objects, or abrasive cleaners to clean the instruments. To remove soiling use soft materials with cleaning solution only. Stage I: Clean Fully immerse all used parts of the completely disassembled device in the cleaning solution for two (2) to five (5) minutes. All accessible surfaces must remain immersed in the cleaning solution throughout the entire cleaning time. Make sure that there are no air bubbles in lumens or cavities. After soaking in the cleaning solution, clean all outer surfaces while all parts are fully immersed in the cleaning solution using a soft, clean, lintfree wipe or a soft bristled brush until visibly clean. Thoroughly brush the cavities of all parts while they are fully immersed in the cleaning solution. Brush until no more residues can be recognized on the brush. For cleaning the sheath, use an 8 mm diameter brush. For cleaning the visual obturator, the sheath's side openings, the hose connectors and the stopcock valves, use a 5 mm diameter brush. Stage II: Rinse

Instructions For Use | 4 - May - 2021 | Version: F

Page 31 of 376

4 Reprocessing 4.6 Detailed Reprocessing Instructions Fully immerse all parts in a tap water bath (less than 45 °C / 113 °F) and rinse all accessible surfaces twice for a minimum of one (1) minute each. Use fresh water for each cycle. Rinse lumens and cavities of all parts at least three (3) times using 50 mL of tap water. Allow water to drip off for a sufficient length of time. Stage III: Final rinse Outside United States: Fully immerse all parts in a deionized water bath (less than 45 °C / 113 °F) and rinse all accessible surfaces for a minimum of one (1) minute each. Rinse lumens and cavities of all parts at least three (3) times using 50 mL of deionized water. Allow water to drip off for a sufficient length of time. United States: Fully immerse all parts in a high purity water bath (less than 45 °C / 113 °F) and rinse all accessible surfaces for a minimum of one (1) minute each. Rinse lumens and cavities of all parts at least three (3) times using 50 mL of high purity water. Allow water to drip off for a sufficient length of time. Stage IV: Dry Thoroughly dry all parts with a clean, lint-free wipe or clean, lint-free cotton weave operating room towels and use medical-quality filtered compressed air (pmax. 0.5 bar) to dry cavities. After drying, perform a visual check in bright ambient light (see section 3.4), and ensure that the device is dry, undamaged and free of visible residue. Repeat the cleaning process if necessary. Remove damaged devices from use immediately. Lubricants (for example, Sterilit® JG600 by BBraun) can be applied to stopcocks for better performance. Lubricant requirements: steam sterilization according to ISO 17665-1 and ANSI/AAMI ST8 microbial efficiency according to ISO 17664 and AAMI TIR 12 biocompatibility testing according to ISO 10993-1 Table 4-2: Manual Cleaning Process Details Stage

Step

Temperature (°C/°F)

Time (min)

Water quality

Cleaning solution

I

Cleaning

(according to manufacturer's instruction)

2-5

Tap water

Enzymatic cleaning solution

II

Rinse 2x

< 45/113

2x ≥1

Tap water

---

III

Final rinse

< 45/113

≥1

Deionized / high purity water

---

IV

Drying

---

---

---

---

4.6.2

Manual Cleaning with Disinfection

Follow the manufacturer’s instructions when preparing the cleaning and disinfection solutions. Manual Cleaning with Disinfection validation was completed with Cidezyme/Enzol (Johnson & Johnson) and CIDEX OPA (Johnson & Johnson). NOTICE! Damage resulting from rough handling. Telescopes contain glass rods that are extremely fragile. Handle the device with care. Do not bump or bend. Set down with care. NOTICE! (Telescopes) Scratch-sensitive surfaces. Risk of abrasion. Do not use metal brushes, metal objects, or abrasive cleaners. To remove soiling on optical surfaces use soft materials with cleaning solution only.

Instructions For Use | 4 - May - 2021 | Version: F

Page 32 of 376

4 Reprocessing 4.6 Detailed Reprocessing Instructions NOTICE! Scratch-sensitive surfaces. Risk of corrosion due to abrasion. Do not use metal brushes, metal objects, or abrasive cleaners to clean the instruments. To remove soiling use soft materials with cleaning solution only. Stage I: Clean - Follow instructions of Section 4.6.1 Stage II: Rinse - Follow instructions of Section 4.6.1 Stage III: Disinfect Fully immerse all parts for a minimum of twelve (12) minutes in the disinfection solution. Remove any air bubbles adhered onto the parts' surfaces. All accessible surfaces must remain immersed in the disinfectant solution bath throughout the entire disinfection time. Stage IV: Rinse - Follow instructions of Section 4.6.1 Stage V: Final rinse - Follow instructions of Section 4.6.1 Stage VI: Dry – Follow instructions of Section 4.6.1 Lubricants (for example, Sterilit® JG600 by BBraun) can be applied to stopcocks for better performance. Lubricant requirements: steam sterilization according to ISO 17665-1 and ANSI/AAMI ST8 microbial efficiency according to ISO 17664 and AAMI TIR 12 biocompatibility testing according to ISO 10993-1 Table 4-3: Manual Cleaning Process with Disinfection Process Details Stage

Step

Temperature (°C/°F)

Time (min)

Water quality

Cleaning solution

I

Cleaning

(according to manufacturer's instruction)

2-5

Tap water

Enzymatic cleaning solution

II

Rinse 2x

< 45/113

2x ≥1

Tap water

---

III

Disinfection

(according to manufacturer's instruction)

12

---

Disinfectant solution (undilued)

IV

Rinse 2x

< 45/113

2x ≥1

Tap water

---

---

---

V

Final rinse

< 45/113

≥1

Deionized / high purity water

VI

Dry

---

---

---

4.6.3

Automated Cleaning (with Thermal Disinfection)

Use cleaning equipment that has been validated as effective and meets the performance requirements of ISO 15883-1 or the relevant country-specific version thereof. Follow the manufacturer’s instructions when preparing the cleaning solution. Automated Cleaning validation was performed with Neodisher MediClean Forte 0.5% (Dr. Weigert GmbH & Co.). CAUTION! Risk of scalding when loading/unloading the device. Wear gloves. NOTICE! Thermal disinfection should be performed only with products that are labeled as autoclavable. NOTICE! Automated cleaning can cause color-anodized or plastic components (e.g. standard rings and the eyepiece of the telescope) to fade. This will not impact device performance. Place the devices in an automated washer/disinfector. When loading avoid rinsing blind spots. Instruments with lumens must be connected to suitable connectors of instrument trays or of the automated washer/disinfector to

Instructions For Use | 4 - May - 2021 | Version: F

Page 33 of 376

4 Reprocessing 4.6 Detailed Reprocessing Instructions ensure appropriate flushing. Open the jaws of instruments to ensure thorough flushing of hinges. Do not stack devices or place them in close contact. Only devices listed in Section 1.3 Device Descriptions should be included in the trays or cases of the automated washer/disinfector. Run the cleaning cycle (Table 4-4) in accordance with the manufacturer’s instructions for the washer/disinfector. Remove the devices from the automated washer/disinfector. After cleaning perform a visual check in bright ambient light (see Section 3.4), and ensure that the device is dry, undamaged and free of visible residue. Repeat the cleaning process if necessary. Remove damaged devices from use immediately. Lubricants (for example, Sterilit® JG600 by BBraun) can be applied to stopcocks for better performance. Lubricant requirements: steam sterilization according to ISO 17665-1 and ANSI/AAMI ST8 microbial efficiency according to ISO 17664 and AAMI TIR 12 biocompatibility testing according to ISO 10993-1 Table 4-4: Automated Cleaning (with Thermal Disinfection) Process Details Stage

Step

Temperature (°C/°F)

Time (min)

Cleaning solution / Water quality

I

Pre-rinse

Cold

2

Tap water

II

Clean

60/140

10

Alkaline detergent

III

Rinse

per the equipment manufacturer's standard cycle

1

Tap water

IV

Rinse

per the equipment manufacturer's standard cycle

1

Tap water

V

Thermal disinfection

90/194

5

Deionized or high purity water

VI

Dry

98.8/210

30

---

4.6.4

High Level Disinfection (HLD) CAUTION! Only perform HLD with cleaned, rinsed, and dried products. Cleaning agents and organic matter residues may have a negative impact on disinfection results.

Follow the manufacturer’s instructions when preparing the disinfection solution. HLD validation was completed with Cidex OPA (Johnson & Johnson). NOTICE! Damage resulting from rough handling. Telescopes contain glass rods that are extremely fragile. Handle the device with care. Do not bump or bend. Set down with care. Stage I: Disinfect Verify the disinfection solution has an acceptable concentration using an original Cidex OPA test strip. Fully immerse all used parts of the completely disassembled device in the disinfection solution for at least twelve (12) minutes. All accessible surfaces must remain immersed in the disinfection solution throughout the entire disinfection time. Make sure that there are no air bubbles in lumens or cavities or adhering to the device’s surface. Stage II: Rinse Thoroughly rinse the device by immersing it completely in a large volume (e.g. 2 gallons/8 litres) of sterile water for at least one (1) minute.

Instructions For Use | 4 - May - 2021 | Version: F

Page 34 of 376

4 Reprocessing 4.6 Detailed Reprocessing Instructions Rinse all cavities and lumens using at least 100 ml of sterile water. Repeat both preceding steps two times (three (3) rinses in total). Use fresh sterile water for each rinse. Do not reuse the rinse water for any purpose. Stage III: Dry Thoroughly dry all parts with a clean, lint-free sterile wipe or towel and use medical-quality filtered compressed air (pmax. 0.5 bar) to dry cavities. After cleaning, visually inspect the device in bright ambient light (see Section 3.4), and ensure that the device is dry, undamaged and free of visible residue. Repeat the disinfection process if necessary. Lubricants (for example, Sterilit® JG600 by BBraun) can be applied to stopcocks for better performance. Lubricant requirements: steam sterilization according to ISO 17665-1 and ANSI/AAMI ST8 microbial efficiency according to ISO 17664 and AAMI TIR 12 biocompatibility testing according to ISO 10993-1 Table 4-5: HLD Process Details Stage

Step

Temperature (°C/°F)

Time (min)

Cleaning solution / Water quality

I

Disinfection

≥ 20/68

12

Cidex OPA

II

Rinse 3x

< 45/113

3x ≥ 1

Sterile water

III

Dry

Room temperature

---

---

4.6.5

Sterilization WARNING! Only use sterilization equipment (biological indicators, barriers and trays) that are FDA-cleared and labeled for use for sterilization with United states parameters. Note: This only applies within the United States. CAUTION! Only perform sterilization with cleaned, rinsed, and dried products. Cleaning agents and organic matter residues may have a negative impact on sterilization results. CAUTION! Risk of scalding when loading/unloading the device. Wear suitable gloves.

NOTICE! Damage resulting from rough handling. Telescopes contain glass rods that are extremely fragile. Handle the device with care. Do not bump or bend. Set down with care. NOTICE! Products can be shock sensitive when hot. Avoid knocking or shaking. NOTICE! Damage resulting from a sudden change in temperature. Allow products to cool to room temperature, do not use additional cooling measures. NOTICE! Steam sterilization should be performed only with products that are labeled as autoclavable. Note: It is the responsibility of the user to establish that the autoclave used meets the appropriate sterilization parameters. Note: This only applies within the United States. Double-wrap the device with two single layers of legally marketed sterilization wrap using a sequential double wrapping technique. Load the wrapped device in the sterilizer.

Instructions For Use | 4 - May - 2021 | Version: F

Page 35 of 376

4 Reprocessing 4.6 Detailed Reprocessing Instructions Devices should be positioned to permit adequate steam circulation and penetration, good air circulation, and sufficient condensate drainage. Do not stack wrapped devices or place them in close contact in the sterilization chamber. Only devices listed in Section 1.4 Device Descriptions should be included in the trays or cases of the sterilizer. Start the sterilization cycle (Table 4.6) in accordance with the manufacturer’s instructions and the parameters appropriate to the institutional, local, and national requirements. Remove products from the autoclave. Ensure that the products remain sterile until unwrapped at the time of use. Table 4-6: Steam sterilization parameters Parameter

Value in United States

Value outside United States

Temperature

270 ºF (132 ºC)

273 ºF (134 ºC)

Holding Time

4 minutes minimum

3 minutes minimum

Minimum Dry Time

30 minutes

No requirement

Cycle type

Prevaccum

Prevaccum

Pulses

4

4

5

Maintenance and Repairs

5.1

Common Issues and Solutions

Table 5-1: Common Issues and Solutions Issue

Possible causes

Solutions

Telescope image cloudy

Glass surfaces soiled

Clean manually, then reprocess (section 4.6), check the water quality

Stubborn deposits on glass surfaces

Remove deposits, then reprocess (section 4.6), check the water quality

Leaky, defective lens system

Send the telescope for repair

Glass surfaces soiled

Clean manually, then reprocess (section 4.6), check the water quality

Stubborn deposits on glass surfaces

Remove deposits, then reprocess (section 4.6), check the water quality

Light guide incorrectly attached to telescope

Check that the light guide is seated properly

Defective fiber optics

Check the fiber optics as per section 3.4

Defective light guide or light source

Check the light guide and light source

Soiled fiber optics

Clean manually, then reprocess (section 4.6), check the water quality

Light guide soiled or defective

Check the light guide (e.g. by illuminating a white surface)

Telescope image too dark, insufficient illumination

Telescope image is yellowed

5.2

Repair

Contact Customer Service for repair information (Appendix A).

Instructions For Use | 4 - May - 2021 | Version: F

Page 36 of 376