1 Page

Preview

Page 1

CLEANING AND STERILIZATION PROTOCOL HTR® Hammer Toe Reaming Implant System

CLEANING

Non-sterile products must be carefully cleaned prior to sterilization. Trained personnel must perform cleaning and mechanical inspection prior to sterilization. Compliance is required with the equipment manufacturer’s user instructions (manual and/or machine cleaning, ultrasound treatment, etc.) and recommendations for chemical detergents. Trilliant Surgical recommends the following cleaning and sterilization instructions:

Recommended Manual Cleaning Instructions:

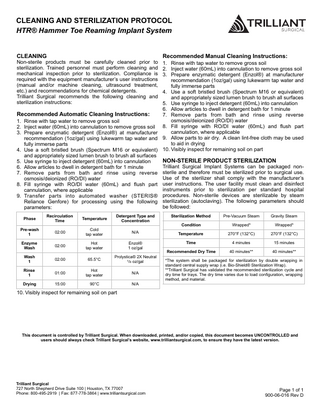

1. Rinse with tap water to remove gross soil 2. Inject water (60mL) into cannulation to remove gross soil 3. Prepare enzymatic detergent (Enzol®) at manufacturer recommendation (1oz/gal) using lukewarm tap water and fully immerse parts 4. Use a soft bristled brush (Spectrum M16 or equivalent) and appropriately sized lumen brush to brush all surfaces 5. Use syringe to inject detergent (60mL) into cannulation 6. Allow articles to dwell in detergent bath for 1 minute Recommended Automatic Cleaning Instructions: 7. Remove parts from bath and rinse using reverse osmosis/deionized (RO/DI) water 1. Rinse with tap water to remove gross soil 2. Inject water (60mL) into cannulation to remove gross soil 8. Fill syringe with RO/DI water (60mL) and flush part cannulation, where applicable 3. Prepare enzymatic detergent (Enzol®) at manufacturer recommendation (1oz/gal) using lukewarm tap water and 9. Allow parts to air dry. A clean lint-free cloth may be used to aid in drying fully immerse parts 4. Use a soft bristled brush (Spectrum M16 or equivalent) 10. Visibly inspect for remaining soil on part and appropriately sized lumen brush to brush all surfaces NON-STERILE PRODUCT STERILIZATION 5. Use syringe to inject detergent (60mL) into cannulation Trilliant Surgical Implant Systems can be packaged non6. Allow articles to dwell in detergent bath for 1 minute 7. Remove parts from bath and rinse using reverse sterile and therefore must be sterilized prior to surgical use. Use of the sterilizer shall comply with the manufacturer’s osmosis/deionized (RO/DI) water 8. Fill syringe with RO/DI water (60mL) and flush part user instructions. The user facility must clean and disinfect instruments prior to sterilization per standard hospital cannulation, where applicable 9. Transfer parts into automated washer (STERIS® procedures. Non-sterile devices are sterilizable by steam Reliance Genfore) for processing using the following sterilization (autoclaving). The following parameters should be followed: parameters: Phase

Recirculation Time

Temperature

Detergent Type and Concentration

Sterilization Method

Pre-Vacuum Steam

Gravity Steam

Condition

Wrapped*

Wrapped*

Pre-wash 1

02:00

Cold tap water

N/A

Temperature

270°F (132°C)

270°F (132°C)

Enzyme Wash

02:00

Hot tap water

Enzol® 1 oz/gal

Time

4 minutes

15 minutes

Recommended Dry Time

40 minutes**

40 minutes**

Wash 1

02:00

65.5°C

Prolystica® 2X Neutral 1/8 oz/gal

Rinse 1

01:00

Hot tap water

N/A

Drying

15:00

90°C

N/A

*The system shall be packaged for sterilization by double wrapping in standard central supply wrap (i.e. Bio-Shield® Sterilization Wrap). **Trilliant Surgical has validated the recommended sterilization cycle and dry time for trays. The dry time varies due to load configuration, wrapping method, and material.

10. Visibly inspect for remaining soil on part

This document is controlled by Trilliant Surgical. When downloaded, printed, and/or copied, this document becomes UNCONTROLLED and users should always check Trilliant Surgical’s website, www.trilliantsurgical.com, to ensure they have the latest version.

Trilliant Surgical 727 North Shepherd Drive Suite 100 | Houston, TX 77007 Phone: 800-495-2919 | Fax: 877-778-3864 | www.trilliantsurgical.com

Page 1 of 1 900-06-016 Rev D